- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

HP potentzia handiko grafito elektrodoa

-

A supplier of graphite electrodes with a global distribution network.

-

Karburizadore granularra

-

Grafito plaka

-

Karburagi esferikoa

-

Grafitoa Gurutzea

-

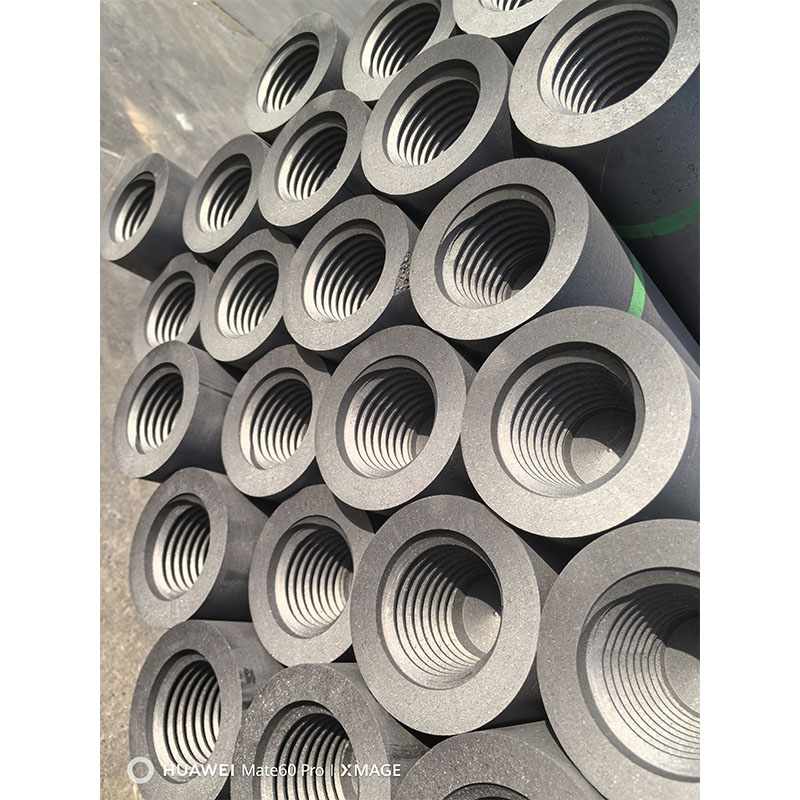

Ultra-High Power Graphite Electrode

-

High-quality graphite powder available in stock, with a full range of specifications and customizable options.

-

600mm diameter high-power and ultra-high-power graphite electrodes, electrically conductive, high-temperature resistant, industrial-grade, stable and durable.

-

High-power graphite electrodes, 600 mm diameter, for export.

-

Cumbarar Carburizador

-

UHP Ultra High Power Grafito Elektrodoa

-

High-temperature resistant silicon carbide crucible, specially designed for melting aluminum and copper, corrosion-resistant and impact-resistant, direct from the manufacturer.

-

High-power graphite electrode rods, specifically for steelmaking and refining. In stock and ready for immediate shipment. Bulk orders receive discounted pricing.

-

Factory direct sale! UHP ultra-high power electrodes, specifically designed for electric arc furnaces and refining furnaces.

-

RP potentzia grafito normala

High-power graphite electrode anti-oxidation coating: high temperature resistance, wear protection, and extended electrode lifespan.

This high-power graphite electrode anti-oxidation coating is specifically developed for high-temperature industrial smelting applications. It utilizes a nano-ceramic composite formula and is manufactured through precise spraying and high-temperature curing processes. The coating is tightly bon...

Deskribapen

markagailu

This high-power graphite electrode anti-oxidation coating is specifically developed for high-temperature industrial smelting applications. It utilizes a nano-ceramic composite formula and is manufactured through precise spraying and high-temperature curing processes. The coating is tightly bonded to the electrode substrate, exhibiting strong adhesion and resistance to peeling.

The coating boasts three core advantages: high-temperature oxidation resistance, low thermal conductivity, and corrosion resistance. It can reduce oxidation loss of the electrode by more than 60% in a 1800℃ high-temperature environment, effectively extending electrode lifespan, reducing replacement frequency, and lowering smelting production costs. It is suitable for various high-power electric arc furnace steelmaking and refining operations, especially for long-cycle continuous production conditions.

Directly supplied from the factory, we support customized coating thickness according to electrode specifications. Each batch of coating undergoes high-temperature performance and adhesion testing, ensuring stable quality. We offer fast delivery of stock items, competitive pricing for large orders, and professional technical guidance on coating application to help businesses achieve efficient and energy-saving production.