- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

550mm ultra-high power/high-power graphite electrodes: Low resistance, high density, and a pioneer in reducing energy consumption

-

Spherical carburizer

-

High-quality graphite powder available in stock, with a full range of specifications and customizable options.

-

Factory direct sale! UHP ultra-high power electrodes, specifically designed for electric arc furnaces and refining furnaces.

-

Ultra-High Power Graphite Electrode

-

RP normal power graphite electrode

-

High-power graphite electrode rods, specifically for steelmaking and refining. In stock and ready for immediate shipment. Bulk orders receive discounted pricing.

-

450mm ultra-high/high-power graphite electrodes, high density and low resistance, supplied directly from the manufacturer.

-

Columnar carburizer

-

High-sulfur and low-sulfur petroleum coke, specifically for metallurgy and casting applications. Directly supplied by the manufacturer, in stock and ready for immediate shipment

-

Graphite plate

-

High-power graphite electrode anti-oxidation coating: high temperature resistance, wear protection, and extended electrode lifespan.

-

High-power graphite electrodes: the preferred choice for energy saving, reduced consumption, and improved steelmaking efficiency

-

600mm ultra-high power graphite electrodes with high density and low resistance: setting a new benchmark for smelting efficiency

-

Nine-hole crucible specifically designed for negative electrode materials; features low impurity content, high temperature resistance, and compatibility with graphitization processes

-

85-1260mm full range coverage, high-power and ultra-high-power graphite electrodes – the energy core of industrial smelting

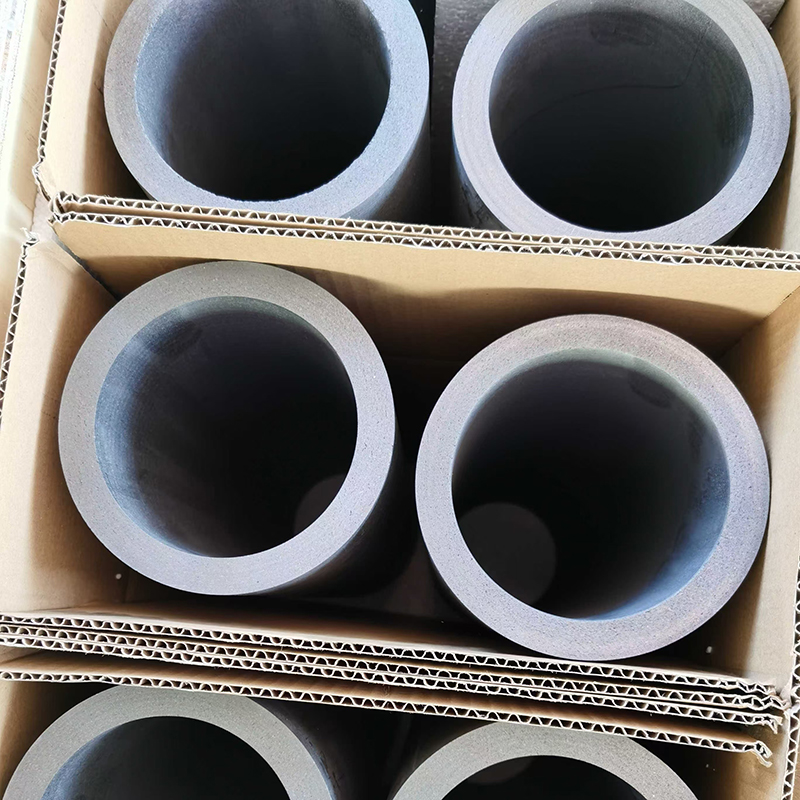

Graphite Crucible

Graphite Crucible Main ingredients and structure •Main ingredients: mainly composed of graphite, usually containing more than 90% carbon, and may also add a small amount of clay, silicon carbide and other additives to improve its performance. •Structural features: It has a typical layered cr...

Description

marker

Graphite Crucible

Main ingredients and structure

•Main ingredients: mainly composed of graphite, usually containing more than 90% carbon, and may also add a small amount of clay, silicon carbide and other additives to improve its performance.

•Structural features: It has a typical layered crystal structure, and the graphite layers are bonded by weak van der Waals forces. This structure gives the graphite crucible good high temperature resistance, conductivity and lubricity.

Performance characteristics

•Strong high temperature resistance: It can withstand high temperatures of 1500℃-2000℃, and can still maintain good stability in high temperature environments, and is not easy to soften and deform.

•Good thermal conductivity: It can quickly and evenly transfer heat, so that the materials in the crucible are heated evenly, which is conducive to chemical reactions and smelting processes, and can improve production efficiency and product quality.

•Good chemical stability: In most chemical environments from room temperature to high temperature, graphite crucibles have good corrosion resistance, are not easy to react with acids, alkalis and other chemicals, can ensure the purity of the processed materials, and are suitable for the smelting and reaction of a variety of chemical substances.

•Good mechanical properties: It has certain strength and impact resistance, is not easy to break during loading and unloading and use, and can withstand certain mechanical stress.

Application areas

•Metal smelting: widely used in the smelting of non-ferrous metals and alloys such as gold, silver, copper, and aluminum. It can provide a high-temperature environment for metal smelting, ensure that the metal is fully melted and evenly mixed, and improve the purity and quality of the metal.

•Chemical experiments: in the laboratory, it is often used for high-temperature chemical reactions, melting experiments, and sample ashing operations. It can be used as a reaction vessel to meet the requirements of various chemical experiments for high temperature and chemical stability.

•Glass manufacturing: in the glass production process, it is used to melt glass raw materials, which helps to improve the melting efficiency and uniformity of the glass and improve the quality and performance of the glass.

Types

•Ordinary graphite crucible: Made of natural graphite and clay, it is relatively cheap and suitable for general metal smelting and experiments.

•High-purity graphite crucible: Made of high-purity graphite raw materials and processed by special technology, it has higher purity, better high temperature resistance and chemical stability. It is suitable for precious metal smelting and high-end chemical experiments with high purity requirements.

•Silicon carbide graphite crucible: Adding materials such as silicon carbide to graphite improves the strength, high temperature resistance and thermal shock resistance of the crucible. It is often used for smelting and reactions in high temperature and highly corrosive environments.