- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

Full range of graphite electrodes: 450, 500, 550 mm sizes available, high-power and ultra-high-power options, all sizes in stock

-

Nine-hole crucible specifically designed for negative electrode materials; features low impurity content, high temperature resistance, and compatibility with graphitization processes

-

HP high power graphite electrode

-

960 Graphite Electrodes – High Power, Ultra-High Power – Worldwide Shipping

-

RP normal power graphite electrode

-

Graphite crucibles specifically designed for negative electrode materials: high temperature resistance and oxidation resistance; ideal for lithium-ion battery production

-

High-power graphite electrode rods, specifically for steelmaking and refining. In stock and ready for immediate shipment. Bulk orders receive discounted pricing.

-

Metallurgical steelmaking ultra-high power graphite electrodes, high temperature resistant and impact resistant, direct supply from the manufacturer

-

Graphite Crucible

-

High-power graphite electrodes: the preferred choice for energy saving, reduced consumption, and improved steelmaking efficiency

-

High-power graphite electrodes, 600 mm diameter, for export.

-

Spherical carburizer

-

A supplier of graphite electrodes with a global distribution network.

-

High-temperature resistant silicon carbide crucible, specially designed for melting aluminum and copper, corrosion-resistant and impact-resistant, direct from the manufacturer.

-

High-power graphite electrode anti-oxidation coating: high temperature resistance, wear protection, and extended electrode lifespan.

-

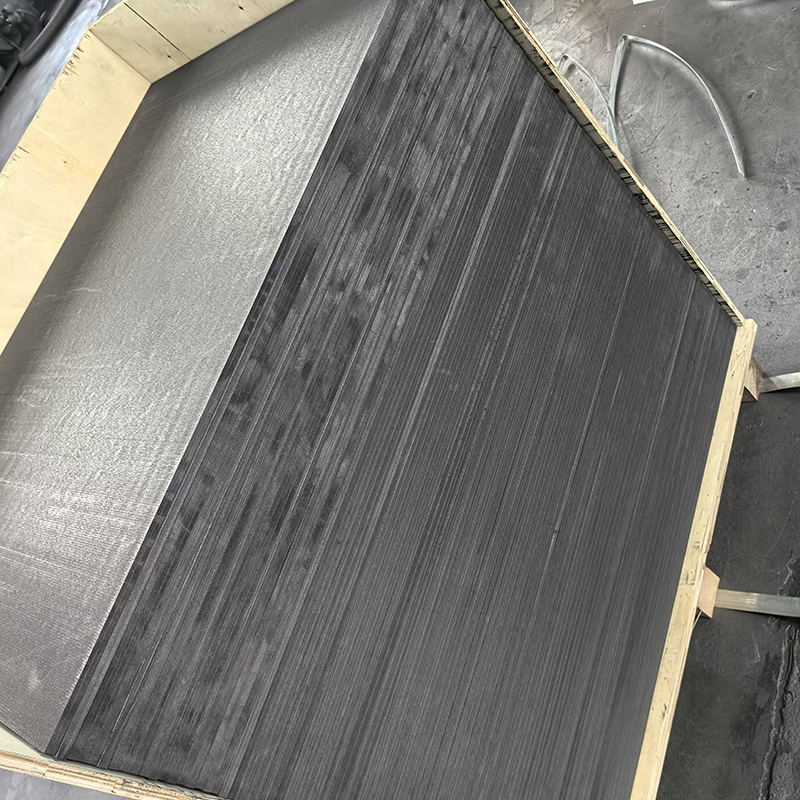

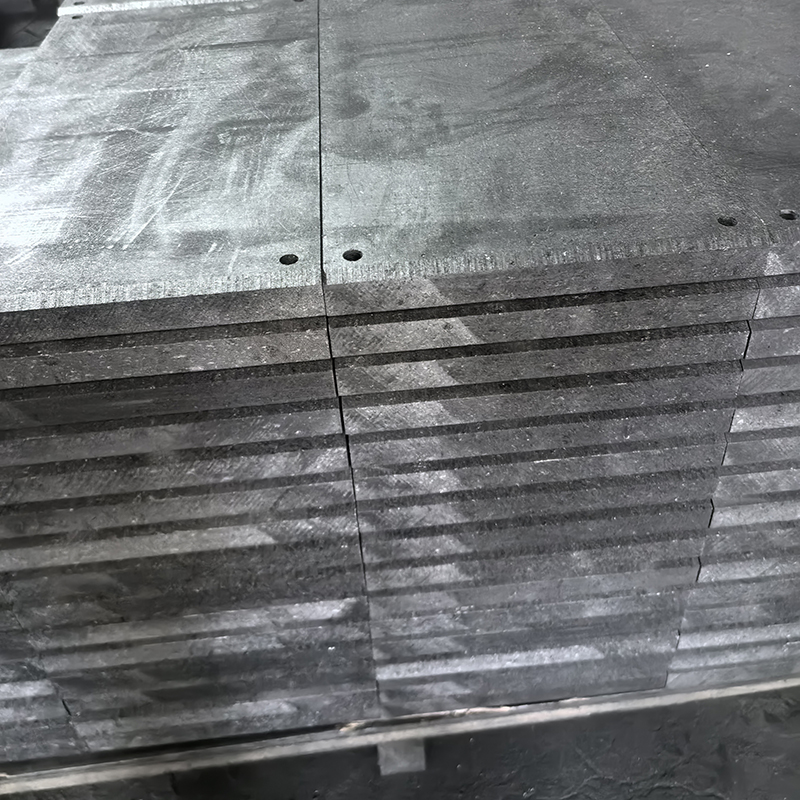

High-temperature resistant graphite plates: conductive, thermally conductive, and corrosion-resistant; custom processing available for industrial furnaces

Graphite plate

Graphite sheet (customizable) Definition and classification •Definition: Graphite plate is a plate made of graphite material after processing, which inherits many excellent properties of graphite. •Classification: According to the purity of raw materials, it can be divided into high-purity g...

Description

marker

Graphite sheet (customizable)

Definition and classification

•Definition: Graphite plate is a plate made of graphite material after processing, which inherits many excellent properties of graphite.

•Classification: According to the purity of raw materials, it can be divided into high-purity graphite plate, ordinary graphite plate, etc.; according to the purpose, it can be divided into electrode graphite plate, refractory graphite plate, lubricating graphite plate, etc.; according to the production process, it can be divided into molded graphite plate, isostatic graphite plate, extruded graphite plate, etc.

Performance characteristics

•Physical properties: It has good thermal stability, can maintain stable physical properties under high temperature environment, and has little performance change when it is cooled or heated suddenly; it has a small thermal expansion coefficient, stable dimensions, and is not easy to deform significantly due to temperature changes; the density is generally between 1.7-2.3g/cm³, which is lighter than metal materials and easy to carry and install.

•Chemical properties: It has good chemical stability, is resistant to corrosion by chemicals such as acids, alkalis, and salts, and can be used in various harsh chemical environments; it has strong oxidation resistance, is not easily oxidized within a certain temperature range, and has a long service life.

•Mechanical properties: It has high strength, good compressive strength and flexural strength, and can withstand certain pressure and external forces; it has good wear resistance, high surface hardness, and is not easy to be worn.

•Electrical properties: It has excellent conductivity, low resistivity, can quickly conduct current, and is widely used in fields that require conductivity; it also has certain electromagnetic shielding properties, which can be used to prevent electromagnetic interference.

•Other properties: It has self-lubricating properties, a small friction coefficient, can work under conditions of no lubrication or less oil lubrication, and reduce equipment wear and energy consumption; it has low air permeability and can be used in occasions that require sealing.

Production process

•Raw material preparation: Select high-purity graphite raw materials, such as natural graphite, artificial graphite, etc., and perform pretreatment such as crushing and grinding to achieve the appropriate particle size requirements.

•Mixing: Mix the graphite raw materials with binders, additives, etc. in a certain proportion to form a mixture with good plasticity.

•Molding: Use compression molding, isostatic pressing, extrusion molding and other methods to make the mixture into graphite sheet blanks of the required shape and size.

•Calcination: Put the blank into the calcining furnace and roast it at high temperature to carbonize the binder and improve the strength and hardness of the graphite sheet.

•Graphitization: The graphite sheet after calcining is graphitized to rearrange the carbon atoms at a higher temperature to form a graphite crystal structure, further improving the performance of the graphite sheet.

•Processing: According to user needs, the graphitized graphite sheet is mechanically processed, such as cutting, drilling, grinding, polishing, etc., to obtain the required dimensional accuracy and surface quality.

Application fields

•Industrial field: In the metallurgical industry, it is used to manufacture refractory materials such as graphite crucibles, ingot protective agents, and smelting furnace linings; in the petrochemical industry, it is used as sealing materials, corrosion-resistant pipes, reactor linings, etc.; in the machinery manufacturing industry, it is used as wear-resistant parts, lubricants, mold materials, etc.

•Electronic and electrical fields: It is an important material for electronic components such as integrated circuits, semiconductor devices, and electron tubes. It can be used to make conductive parts such as electrodes, brushes, electric rods, and carbon tubes; in the field of new energy batteries, it is used as an electrode material or battery diaphragm material for lithium-ion batteries and fuel cells.

•Aerospace and nuclear energy fields: Due to its light weight, high strength, high temperature resistance, and radiation resistance, it is used to manufacture aerospace aircraft components such as thrusters, wings, and wheels; in the field of nuclear energy, it can be used as a neutron moderator, reflective layer material, and core structure material for nuclear reactors.

•Architecture and home furnishing: It can be used in exterior wall insulation systems, with good fire prevention, heat insulation and thermal insulation performance; it can also be used as floor paving materials, wall decoration materials, furniture making materials, etc., to add a sense of fashion and unique texture to the home space.

•Other fields: In the field of environmental protection, it can be used for sewage treatment, air purification, etc.; in the field of biomedicine, it can be used to prepare biosensors, drug carriers, artificial joints, etc.; in the military field, it can be used to manufacture pyrotechnic material stabilizers, electromagnetic shielding materials, etc.

Packaging and Delivery

Packing Details: Standard packaging in pallet.

Port: Tianjin Port