- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

RP Qub Zog Graphite Hluav Taws Xob

-

Tag nrho ntau yam ntawm graphite electrodes: 450, 500, 550 mm qhov ntau thiab tsawg muaj, muaj zog thiab ultra-high-power xaiv, txhua qhov ntau thiab tsawg hauv Tshuag

-

High-sulfur thiab low-sulfur petroleum coke, tshwj xeeb tshaj yog rau metallurgy thiab casting daim ntaub ntawv. Muab khoom ncaj qha los ntawm cov chaw tsim khoom, hauv Tshuag thiab npaj rau kev xa khoom sai

-

Graphite crucibles tshwj xeeb tsim rau cov khoom tsis zoo electrode: kub tsis kam thiab oxidation tsis kam; zoo tagnrho rau lithium-ion roj teeb ntau lawm

-

960 Graphite Electrodes - Lub Hwj Chim Siab, Ultra-High Power - Kev xa khoom thoob ntiaj teb

-

Metallurgical steelmaking ultra-siab zog graphite electrodes, kub resistant thiab cuam tshuam resistant, khoom ncaj qha los ntawm cov chaw tsim tshuaj paus

-

High-power graphite electrodes: qhov kev xaiv zoo tshaj plaws rau kev txuag hluav taws xob, txo kev noj, thiab txhim kho steelmaking efficiency

-

High-power graphite electrode rods, tshwj xeeb tshaj yog rau steelmaking thiab refining. Hauv Tshuag thiab npaj rau kev xa khoom sai. Kev txiav txim ntau tau txais luv nqi.

-

450mm ultra-high / high-power graphite electrodes, siab ceev thiab tsis muaj zog, nkag ncaj qha los ntawm cov chaw tsim khoom.

-

Kheej kheej carburizer

-

85-1260mm tag nrho cov kev pab cuam, high-power thiab ultra-high-power graphite electrodes - lub zog tseem ceeb ntawm industrial smelting

-

600mm ultra-siab zog graphite electrodes nrog siab ceev thiab tsis kam: teeb tsa tus qauv tshiab rau smelting efficiency

-

Calcined petroleum coke carbon additive: siab nqus tus nqi, adjustable particle loj, zoo tagnrho rau casting thiab metallurgy

-

High-power graphite electrode anti-oxidation txheej: kub tsis kam, hnav tiv thaiv, thiab txuas ntxiv electrode lifespan.

-

UHP Ultra High Fais Fab Graphite Hluav Taws Xob

-

Cuaj-qhov crucible tshwj xeeb tsim rau cov khoom tsis zoo electrode; nta cov ntsiab lus uas tsis muaj impurity, siab kub tsis kam, thiab compatibility nrog cov txheej txheem graphitization

HP Lub Zog Hluav Taws Graphite Hluav Taws Xob

HP lub zog loj graphite: hom kab mob hluav taws xob hauv electrode: 1600 ~ iTallal expardion: 100-165

Kev piav txog

tus cim

HP Lub Zog Hluav Taws Graphite Hluav Taws Xob

Cov lus piav qhia luv luv:

Hom: HP graphite electrode

Daim Ntawv Thov: Hlau / Hlau Hlau

Ntev: 1600 ~ 2800mm

Qib: HP (High Fiber)

Kuj (μω.m): 5.8-6.6

Pom meej ntom ntom (g / cm³): 1.65-1.70 Nws

Thermal Expansion: 100-600 3DI / 4pi / 4pil

Cov Khoom Siv Raw: Koob coke, roj av coke, thee tar pitch

Hom tau zoo: Tsawg Siv Tus Nqi

Xim: Black dub

Inch: 250 hli, 300mm, 400mm, 400mm, 450mm, 600mm, 600mm, 800mm, 800mm, 800mm, 800mm

•Cov yam ntxwv ua tau zoo

•Siab zoo: Kev tiv thaiv qis tsis tau, nruab nrab ntawm 5.8-6.6Hen ·, tuaj yeem ua kev coj ua tau zoo, txhim kho kev ruaj khov thiab ua kom ceev nrawm thaum 18-25a / cm².

•Zoo siab siab tiv thaiv kub: Ua los ntawm cov khoom siv raw xws li roj cream thiab koob tshuaj, tom qab kev kub ntxhov hauv lub cev thiab tsis yooj yim rau deform lossis kev puas tsuaj.

•Xav muaj zog txhua yam: Nws muaj qhov khoov rau nws lub zog thiab cuam tshuam tsis kam, ≥11.0MPA, tuaj yeem tiv thaiv kom yooj yim thaum siv, thiab ua kom muaj kev ruaj khov thiab pabcuam lub neej ntawm electrode.

•Zoo thermal poob siab: Nyob rau hauv cov txheej txheem ntawm cov cua sov nquag thiab yuav tawm tsam cov nyhuv ntawm kev ntxhov siab thermal, tev tawm, tev tawm, tev tawm, thiab lwm yam kev ruaj khov ntawm electrode.

•Cov ntsiab lus tshauv tsawg: hmoov av ≤0,2%, tsawg dua impurities, tuaj yeem txo cov kuab paug ntawm molten

•Cov txheej txheem ntau lawm

•Xaiv cov khoom siv Raw: Roj roj Coke thiab koob Coke yog qhov sib xyaw ua ke tseem ceeb, thiab ntim cov tawv ntoo yog lub phau ntawv. Ntawm lawv, koob coke account rau li 30%, thiab nws lub zog siab, siab zog thiab siab thermal ruaj khov kom txhim kho cov khoom hluav taws xob.

•Kho: Caline cov ntaub ntawv nyoos ntawm qhov kub kom tshem tawm impurities xws li noo noo thiab lub zog ntawm cov khoom siv raw, thiab txhim kho lawv cov kev coj ua thiab thermal ruaj khov.

•Crushing thiab sib tsoo: Kev sib tsoo thiab sib tsoo cov ntaub ntawv uas muaj calhined kom ua tiav qhov tsim nyog particle loj faib rau kev sib txuas lus ntxiv thiab cov txheej txheem kneading.

•Batching thiab Kneading: Ntau cov ntaub ntawv raw yog tsoo raws li ib qho kev faib ua feem, thiab ib qho tsim nyog ntawm cov phaj thee yog ntxiv ua phau ntawv. Kneading yog nqa tawm ntawm qhov kub kom siab muab cov khoom siv raw thiab ua ib cov tshuaj txhuam nrog cov yas zoo.

•Moulding: Lub kneaded paste yog muab tso rau hauv cov pwm, thiab electrode dawb paug ntawm cov duab uas yuav tsum tau thiab loj yog ua los ntawm extrusion, molding thiab lwm yam moulding txoj kev.

•Kho: Cov hluav taws xob tsis muaj hluav taws xob yog calcined thaum muaj cua sov nyob rau hauv cov huab cua-nruj me ntsis rau cov pob zeb thee, txhim kho lub zog ntawm cov hluav taws xob, thiab txuas ntxiv tshem tawm impurities.

•Impregnation: Cov calcers electrode yog raus rau hauv cov kua impregnating, xws li siv cov nplaim hluav taws xob thiab lub zog los ua kom muaj qhov hws thiab lub zog thiab oxidation tsis kam ntawm electrode.

•Graphitizitizitization: Lub tshuab hluav taws xob impregnated yog graphitized nyob rau hauv lub siab--graphitization rauv taws ua kom hloov kho cov qauv siv roj nplaum, yog li kev coj ua zoo thiab kub ua rau ntawm cov electrode.

•Machining: Lub graphitized electrode yog kev siv tshuab ua, xws li tig, tho, thiab lwm yam, los tsim cov khoom siv hluav taws xob uas tau raws li cov kev xav tau ntawm cov khoom siv hluav taws xob raug thiab cov lus lossis cov ntawv sib txuas rau kev sib txuas ua tiav.

•Daim Ntawv Thov

•Fais arc rauve steelmaking: Nws yog qhov tseem ceeb ntawm high-zog hluav taws xob arc rauv me me, ua kom cov cua sov lub zog rau hauv lub zog cua sov, txhim kho cov hluav taws xob hluav taws xob, ua kom zoo dua kev siv hluav taws xob thiab qhov zoo, thiab txo qis zog kev noj haus.

•Cov hlau uas tsis yog ferrous: Nyob rau hauv cov txheej txheem smelting ntawm cov tsis muaj hlau xws li tooj liab, txhuas, thiab zinc, ua kom zoo nkauj thiab ua kom zoo dua qub thiab kev ua tau zoo ntawm cov hlau.

•Lwm Teb: Nws kuj tseem siv tau rau hauv daj phosphorus ntau lawm, kev lag luam silicon smelting, abrasive ua kom muaj hluav taws xob kom tau raws li cov kev xav tau ntawm lawv cov txheej txheem ntau lawm.

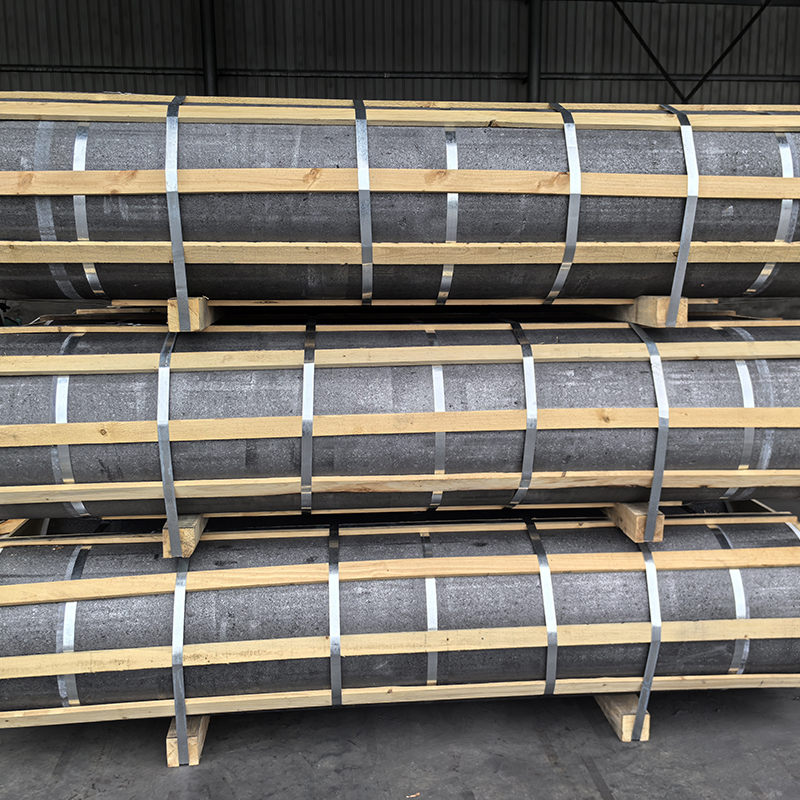

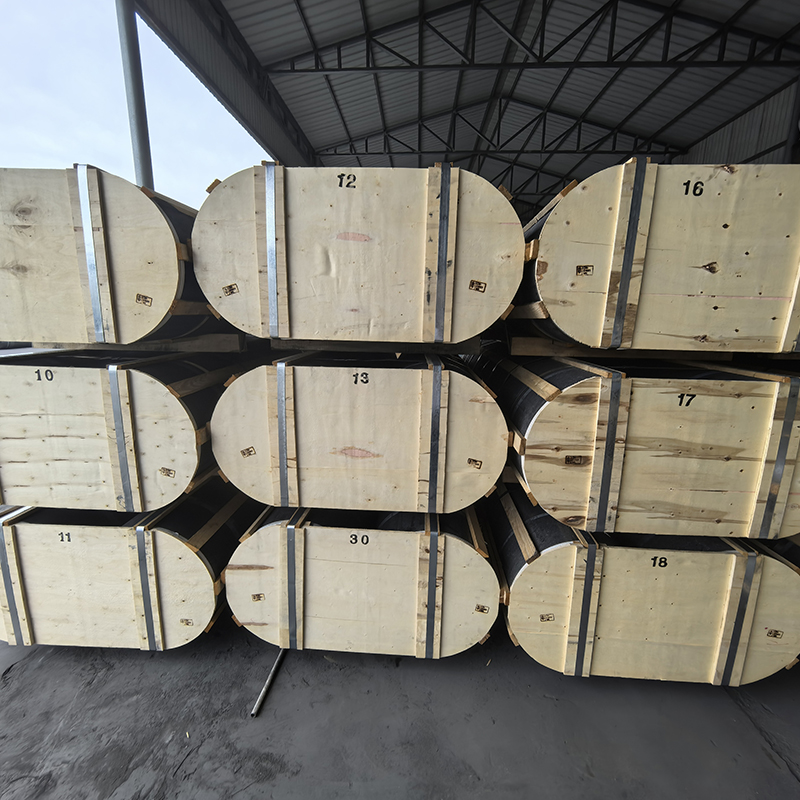

Ntim thiab xa khoom

Cov ntaub ntawv ntim: txheem ntim hauv pallet.

Chaw nres nkoj: Tianjin chaw nres nkoj