- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

Ultra-High Power Graphite Electrode

-

High-power graphite electrode rods, specifically for steelmaking and refining. In stock and ready for immediate shipment. Bulk orders receive discounted pricing.

-

UHP ultra high power graphite electrode

-

Granular carburizer

-

High-temperature resistant graphite plates: conductive, thermally conductive, and corrosion-resistant; custom processing available for industrial furnaces

-

Full range of graphite electrodes: 450, 500, 550 mm sizes available, high-power and ultra-high-power options, all sizes in stock

-

Graphite plate

-

High-quality graphite powder available in stock, with a full range of specifications and customizable options.

-

Nine-hole crucible specifically designed for negative electrode materials; features low impurity content, high temperature resistance, and compatibility with graphitization processes

-

A supplier of graphite electrodes with a global distribution network.

-

High-power graphite electrode anti-oxidation coating: high temperature resistance, wear protection, and extended electrode lifespan.

-

High-power graphite electrodes: the preferred choice for energy saving, reduced consumption, and improved steelmaking efficiency

-

960 Graphite Electrodes – High Power, Ultra-High Power – Worldwide Shipping

-

Graphite crucibles specifically designed for negative electrode materials: high temperature resistance and oxidation resistance; ideal for lithium-ion battery production

-

450mm ultra-high/high-power graphite electrodes, high density and low resistance, supplied directly from the manufacturer.

-

Calcined petroleum coke carbon additive: high absorption rate, adjustable particle size, ideal for casting and metallurgy

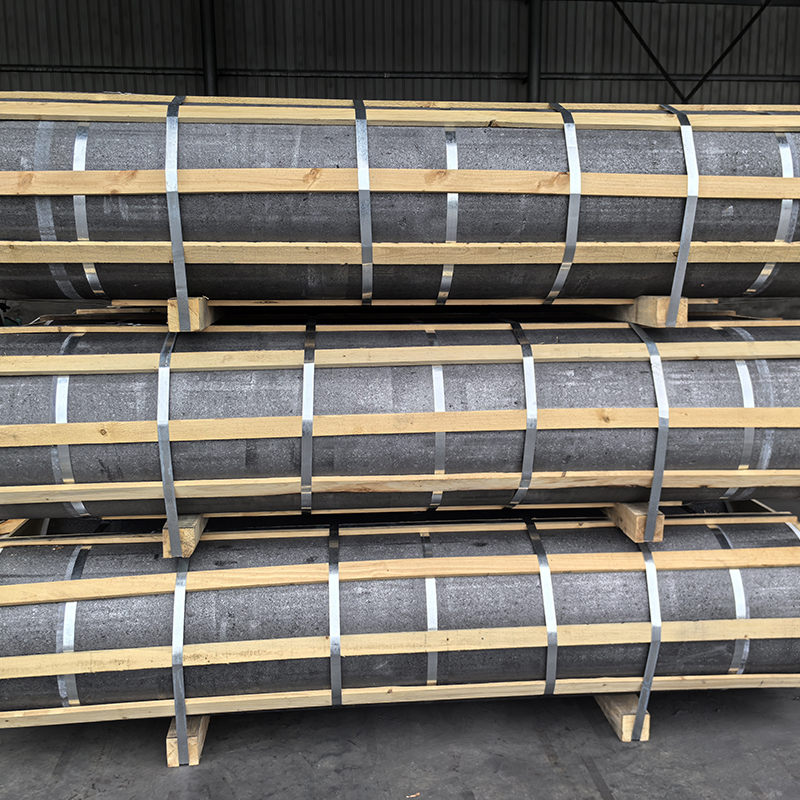

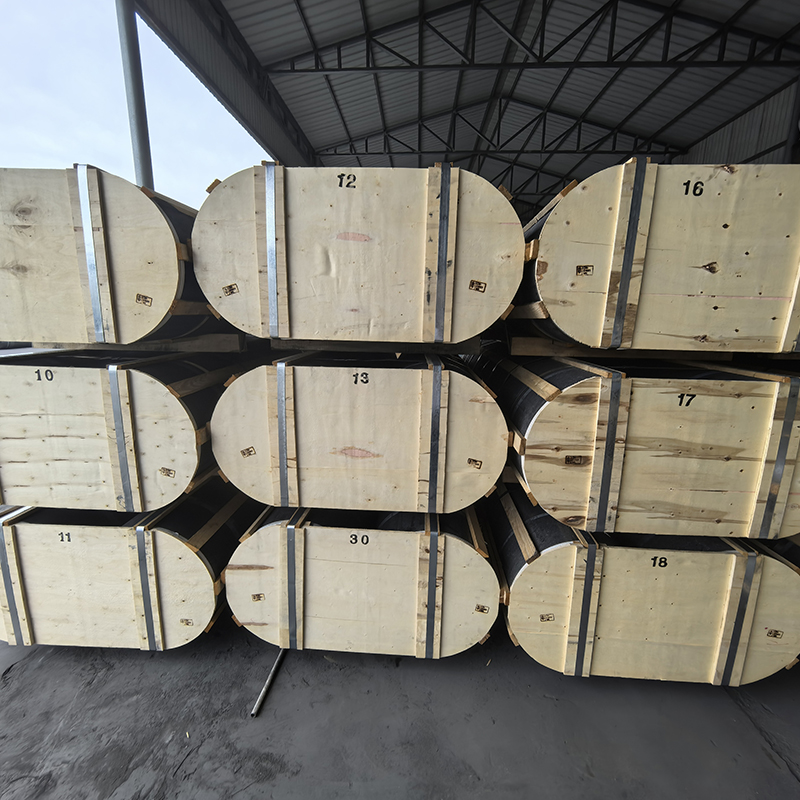

HP high power graphite electrode

HP high power graphite electrode Short description: Type: HP graphite electrode Application: steel/metallurgical steel Length: 1600~2800mm Grade: HP (high power) Resistance (μω.m): 5.8-6.6 Apparent density (G/CM³): 1.65-1.70 Thermal expansion: 100-600 3TPI/4TPI/4TPIL Raw materials: needle coke...

Description

marker

HP high power graphite electrode

Short description:

Type: HP graphite electrode

Application: steel/metallurgical steel

Length: 1600~2800mm

Grade: HP (high power)

Resistance (μω.m): 5.8-6.6

Apparent density (G/CM³): 1.65-1.70

Thermal expansion: 100-600 3TPI/4TPI/4TPIL

Raw materials: needle coke, petroleum coke, coal tar pitch

Advantage: low consumption rate

Color: black grey

Diameter: 250mm, 300mm, 400mm, 400mm, 450mm, 450mm, 500mm, 600mm, 650mm, 650mm, 700mm, 800mm, 800mm, 800mm

•Performance characteristics

•High conductivity: low resistivity, between 5.8-6.6μΩ・m, can efficiently conduct current, reduce energy loss, improve arc stability and efficiency, and allow current density between 18-25A/cm².

•Good high temperature resistance: Made of high-quality raw materials such as petroleum coke and needle coke, after high-temperature treatment, it can maintain stable physical and chemical properties in high temperature environment and is not easy to deform or damage.

•High mechanical strength: It has high bending strength and impact resistance, ≥11.0MPa, can withstand greater stress and impact, is not easy to break during use, and ensures the stability and service life of the electrode.

•Good thermal shock resistance: In the process of frequent heating and cooling cycles, it can resist the effect of thermal stress, is not easy to crack, peel off, etc., and improves the durability of the electrode.

•Low ash content: ash content ≤0.2%, less impurities, can reduce the pollution of molten

•Production process

•Raw material selection: Petroleum coke and needle coke are the main aggregates, and coal tar is the binder. Among them, needle coke accounts for about 30%, and its high strength, high conductivity and high thermal stability are crucial to improving electrode performance.

•Calcination: Calcine the raw materials at high temperature to remove impurities such as moisture and volatiles, increase the density and strength of the raw materials, and improve their conductivity and thermal stability.

•Crushing and grinding: Crushing and grinding the calcined raw materials to achieve a suitable particle size distribution for subsequent batching and kneading processes.

•Batching and kneading: Various raw materials are batched according to a certain proportion, and an appropriate amount of coal tar is added as a binder. Kneading is carried out at high temperature to fully mix the raw materials and form a paste with good plasticity.

•Molding: The kneaded paste is placed in a mold, and the electrode blank of the required shape and size is made by extrusion, molding and other molding methods.

•Calcination: The electrode blank is calcined at high temperature under air-tight conditions to carbonize the coal tar, improve the strength and conductivity of the electrode, and further remove impurities.

•Impregnation: The calcined electrode is immersed in a liquid impregnating agent, such as coal tar, resin, etc., and the impregnating agent penetrates into the pores of the electrode at a certain temperature and pressure to fill the pores and improve the density, strength and oxidation resistance of the electrode.

•Graphitization: The impregnated electrode is graphitized in a high-temperature graphitization furnace to convert amorphous carbon into a graphite crystal structure, thereby improving the conductivity, thermal conductivity and high temperature resistance of the electrode.

•Machining: The graphitized electrode is mechanically processed, such as turning, drilling, tapping, etc., to produce electrode products that meet the requirements of dimensional accuracy and surface quality, and at the same time, threads or joints for connection are processed.

•Application fields

•Electric arc furnace steelmaking: It is a key component of high-power electric arc furnace steelmaking, used to conduct current, generate electric arc, convert electrical energy into heat energy, make the furnace charge melt and refine quickly, improve steelmaking efficiency and quality, and reduce energy consumption.

•Non-ferrous metal smelting: In the smelting process of non-ferrous metals such as copper, aluminum, and zinc, it is used to provide high-temperature heat source, promote the melting and refining of metals, and improve the purity and quality of metals.

•Other fields: It can also be used in yellow phosphorus production, industrial silicon smelting, abrasive manufacturing and other industries to provide electrical conduction and heating functions for the electric furnaces in these industries to meet the requirements of their production processes.

Packaging and Delivery

Packing Details: Standard packaging in pallet.

Port: Tianjin Port