- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

How is bituminous coal tar used in industries today?

2025-10-18

Bituminous coal tar, the thick and sticky byproduct of coal processing, often flies under the radar when people discuss industrial materials. Yet, its role in modern industries is crucial and multifaceted. But how exactly is this substance harnessed in today’s industrial landscape? Let’s explore the practical applications and peculiarities you might not hear about in your everyday discussions.

The Role of Bituminous Coal Tar in Construction

One of the most common uses of bituminous coal tar is in the construction sector, specifically for paving roads and sealing surfaces. Its waterproofing properties make it a prime candidate for road construction. Now, I’ve seen projects where the application was hurried, resulting in uneven surfaces. The timing and method of application can make all the difference to the final product. It’s a bit of an art combined with science.

In practice, various additives are sometimes mixed to enhance the material’s properties. This can include anything from natural fibers to synthetic elements, all in the quest for durability and surface smoothness. Technicians often conduct trial runs to determine the best mix, which can be time-consuming but crucial for areas exposed to heavy traffic and extreme weather conditions.

It’s also worth mentioning that environmental regulations are influencing changes in the formulation of these mixtures. As industries strive to be more eco-friendly, bituminous coal tar is being scrutinized for its environmental impact. Research and development play significant roles here, aiming to balance performance with sustainability.

The Industrial Use in Waterproofing

Another significant application is waterproofing solutions. For its sheer ability to resist water ingress, bituminous coal tar remains in heavy rotation across industries like roofing and industrial tank linings. The CRC Petroleum Handbook discusses these applications, and it’s a must-read for anyone in the trade.

Application techniques are crucial—as any leak in these systems can lead to catastrophic failures. A former colleague of mine learned this the hard way when a hastily applied layer led to a slow seepage issue that took months to remediate. Such errors underline the importance of skill over merely following a protocol.

Being in the field, I can tell you that recent technology has allowed for faster applications and better coverage, reducing the margin for error. Companies now offer specialized equipment to make the process more efficient—this is where experience counts, especially when training new hires to handle the equipment properly.

Insights from Hebei Yaofa Carbon Co., Ltd.

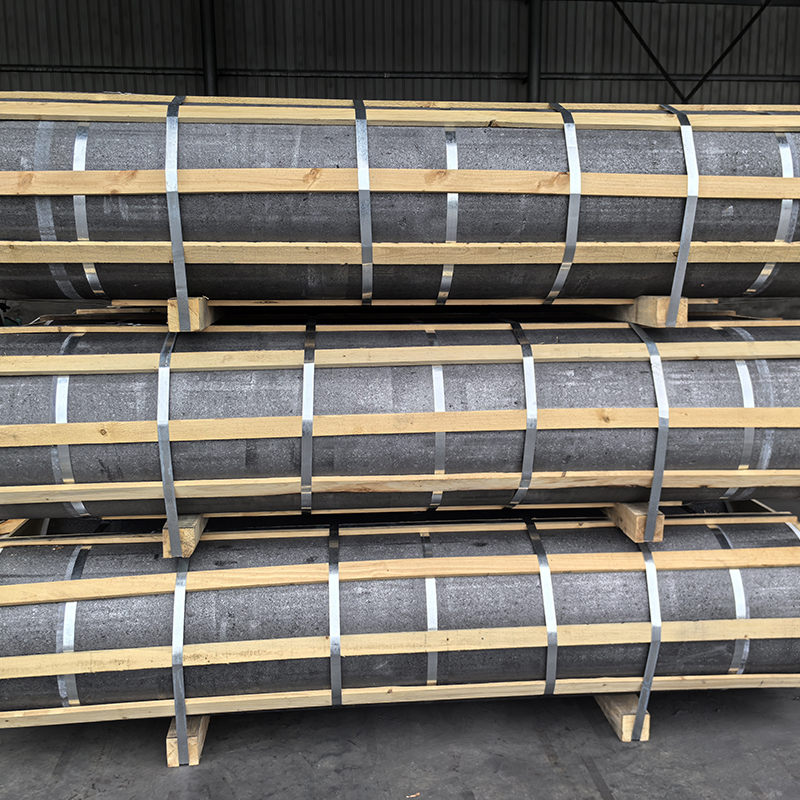

Hebei Yaofa Carbon Co., Ltd., found at yaofatansu.com, offers a variety of carbon materials that often complement coal tar applications. With over 20 years of experience in carbon manufacturing, their expertise shines through in innovative products that support both efficiency and durability.

They produce carbon additives used in enhancing the properties of bituminous coal tar, making it more adaptable for different industrial needs. From their state-of-the-art facilities in China, these products find their way into many global markets, symbolizing the international demand for reliable carbon solutions.

Close collaborations with their team have allowed many companies to refine their processes, tweaking traditional methods with modern technology—an approach that is quite necessary in today’s competitive industrial environment.

Considerations for Environmental Impact

While bituminous coal tar is effective, it’s not without environmental concerns. Industries are increasingly mindful of waste management and emissions. The trend is toward greener alternatives, but the challenge lies in maintaining performance.

In Europe, for example, stricter environmental laws have sparked innovation. Coal tar producers are exploring low-emission formulas to meet the regulatory demands without sacrificing quality. These ongoing developments signal a shift, emphasizing sustainability as a core principle rather than a peripheral goal.

As for future prospects, we’re likely to see a steady rise in bio-based alternatives, which could complement existing coal tar applications. This transition won’t happen overnight but is undeniably the direction in which the industry is heading.

Challenges and Innovations in Application

Applying bituminous coal tar might sound straightforward but involves complex decision-making processes. Different industries have varying specifications and challenges—what works for road construction might not suit roofing applications.

For instance, the temperature and humidity levels during application can lead to varying results. In regions with extreme weather, companies often use technologies that allow real-time monitoring of these environmental factors to tweak on-the-go.

In the end, choosing the right formulation and application method requires both an understanding of the material itself and the specific industrial requirements. As innovations continue, those who stay informed and adaptable will likely have the edge in utilizing bituminous coal tar effectively.