- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

What’s a recarburizer’s purpose?

2025-07-22

Recarburizer Meaning: A Comprehensive GuideRecarburizer is a crucial element in steelmaking, impacting the final product’s properties significantly. This article provides a comprehensive understanding of what a recarburizer is, its types, applications, and importance in various industries. We’ll explore the chemistry behind its function and examine best practices for its use.

What is a Recarburizer?

A recarburizer is a material added to molten iron or steel to increase its carbon content. During the steelmaking process, carbon is often removed to achieve the desired properties. However, many steel grades require a specific carbon level to meet their performance requirements. This is where recarburizers play a vital role. They carefully introduce carbon back into the melt, allowing for precise control over the final steel composition. The choice of recarburizer depends on factors like the desired carbon content, the steelmaking process, and cost considerations. Understanding the meaning of recarburizer is fundamental to achieving high-quality steel products.

Types of Recarburizers

Several types of recarburizers are available, each with unique characteristics and applications:

- Coke: A traditional and widely used recarburizer, coke is relatively inexpensive but can introduce impurities. It is frequently employed in blast furnaces and other high-temperature processes.

- Petroleum Coke: A byproduct of petroleum refining, petroleum coke offers a higher carbon content compared to conventional coke, leading to improved efficiency. However, it might contain higher levels of sulfur, requiring careful control.

- Coal Tar Pitch: A viscous material produced from coal tar, coal tar pitch is used as a recarburizer particularly in the production of graphite electrodes.

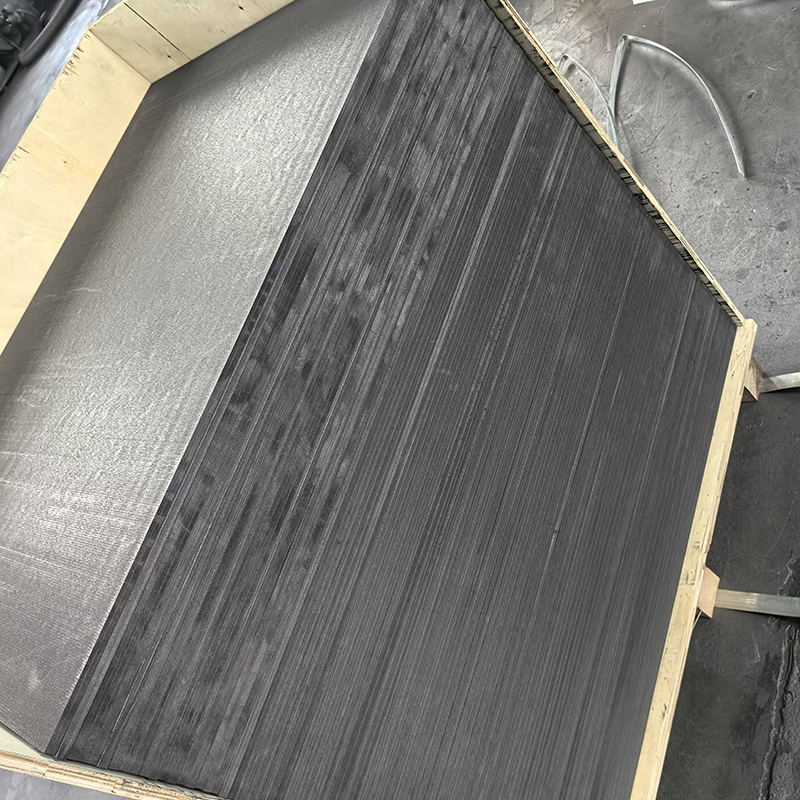

- Graphite: Highly pure graphite provides a clean and efficient way to increase carbon content, minimizing impurity introduction. It is frequently preferred in applications where high purity is essential.

- Synthetic Recarburizers: These are specially formulated materials designed to provide precise carbon additions while minimizing unwanted elements. They offer high purity and consistency, making them suitable for high-value steel applications.

Applications of Recarburizers

The application of recarburizers spans various steelmaking processes and industries. They are crucial for producing a wide range of steel grades, each requiring specific carbon levels for desired properties.

Steelmaking Processes

Recarburizers are integral to various steelmaking processes, including:

- Basic Oxygen Furnace (BOF): Widely used for steelmaking, the BOF process often requires recarburizer addition to achieve the target carbon content.

- Electric Arc Furnace (EAF): EAF processes also utilize recarburizers to adjust the carbon content in the molten steel.

- Induction Furnace: Similar to the EAF, induction furnaces use recarburizers for precise carbon control.

Choosing the Right Recarburizer

Selecting the appropriate recarburizer is crucial for achieving the desired steel properties and optimizing the overall steelmaking process. Factors to consider include:

| Factor | Considerations |

|---|---|

| Carbon Content | The desired carbon level in the final steel product dictates the type and amount of recarburizer needed. |

| Purity | Impurities can negatively affect the steel’s quality. High-purity recarburizers are crucial for demanding applications. |

| Cost | The cost of the recarburizer should be considered in relation to its overall contribution to the steelmaking process. |

| Reaction Rate | The speed at which the recarburizer reacts with the molten metal is important for efficient process control. |

Conclusion

Understanding the meaning and application of recarburizers is essential for anyone involved in steelmaking or related industries. By carefully selecting the appropriate recarburizer and managing its addition to the melt, steel producers can ensure consistent product quality and meet the demanding requirements of diverse applications. For high-quality recarburizers, consider exploring the offerings of reputable suppliers like Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/). They provide a wide range of recarburizers to meet various industrial needs.