- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

High-sulfur and low-sulfur petroleum coke, specifically for metallurgy and casting applications. Directly supplied by the manufacturer, in stock and ready for immediate shipment

-

Factory direct sale! UHP ultra-high power electrodes, specifically designed for electric arc furnaces and refining furnaces.

-

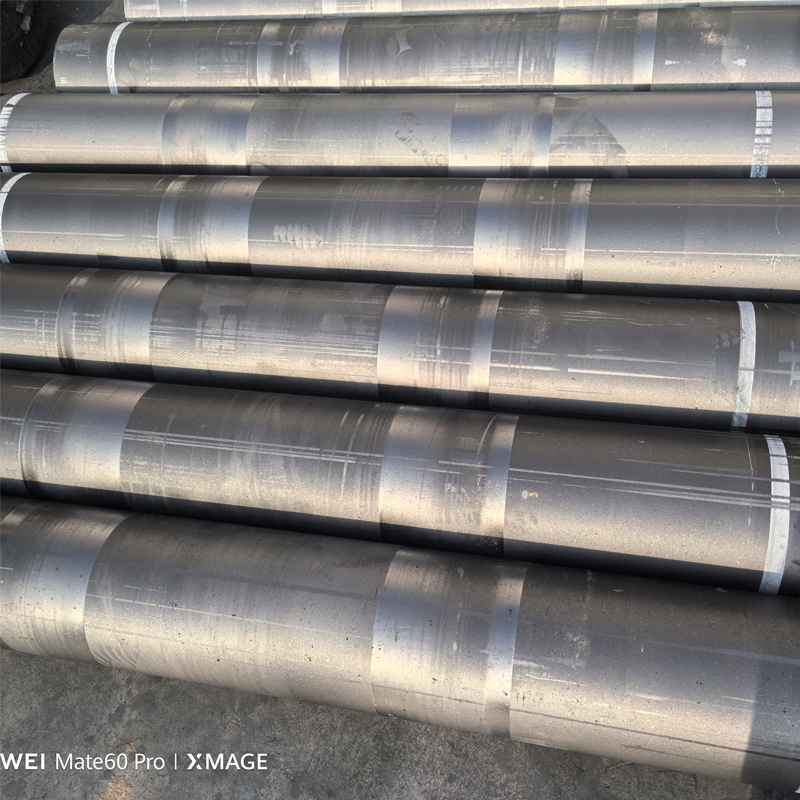

85-1260mm full range coverage, high-power and ultra-high-power graphite electrodes – the energy core of industrial smelting

-

Columnar carburizer

-

Graphite crucibles specifically designed for negative electrode materials: high temperature resistance and oxidation resistance; ideal for lithium-ion battery production

-

High-power graphite electrodes, 600 mm diameter, for export.

-

High-temperature resistant graphite plates: conductive, thermally conductive, and corrosion-resistant; custom processing available for industrial furnaces

-

Graphite Crucible

-

UHP ultra high power graphite electrode

-

Full range of graphite electrodes: 450, 500, 550 mm sizes available, high-power and ultra-high-power options, all sizes in stock

-

Calcined petroleum coke carbon additive: high absorption rate, adjustable particle size, ideal for casting and metallurgy

-

HP high power graphite electrode

-

Granular carburizer

-

960 Graphite Electrodes – High Power, Ultra-High Power – Worldwide Shipping

-

High-power graphite electrodes: the preferred choice for energy saving, reduced consumption, and improved steelmaking efficiency

-

A supplier of graphite electrodes with a global distribution network.

Metallurgical steelmaking ultra-high power graphite electrodes, high temperature resistant and impact resistant, direct supply from the manufacturer

Ultra-high power graphite electrodes are a core consumable in modern electric arc furnace steelmaking, specifically designed for the high-current, high-temperature smelting scenarios in steel plants. They can generate temperatures exceeding 3000°C through a high-intensity arc, enabling rapid m...

Description

marker

Ultra-high power graphite electrodes are a core consumable in modern electric arc furnace steelmaking, specifically designed for the high-current, high-temperature smelting scenarios in steel plants. They can generate temperatures exceeding 3000°C through a high-intensity arc, enabling rapid melting of scrap steel and refining of molten steel. The product is made from 100% imported needle coke, processed through three impregnations and four baking cycles, and high-temperature graphitization, resulting in top-tier performance: bulk density ≥1.69 g/cm³, resistivity ≤5.5 μΩm, thermal expansion coefficient ≤1.5×10⁻⁶/℃, and flexural strength ≥12.0 MPa, with superior joint performance (bulk density ≥1.75 g/cm³, resistivity ≤4.5 μΩm).

Suitable for 145-ton and larger ladle refining furnaces, the refining time is only 11-15 minutes per furnace, with electrode consumption as low as 0.30 kg/ton of steel, saving over 15% energy compared to ordinary electrodes and increasing smelting efficiency by 20%. The product features tightly fitting joints, resistance to extreme temperature differences and electromagnetic vibration, and no risk of detachment or breakage, effectively ensuring continuous production in steel plants, reducing overall operating costs, and serving as a key supporting material for the green upgrade of short-process steelmaking.