- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Furnace Graphite Electrodes: A Comprehensive Guide

2025-05-12

Furnace Graphite Electrodes: A Comprehensive GuideThis article provides a detailed overview of furnace graphite electrodes, covering their manufacturing process, applications, properties, and selection criteria. It aims to equip readers with a comprehensive understanding of this crucial component in various high-temperature industrial processes.

Furnace Graphite Electrodes: A Comprehensive Guide

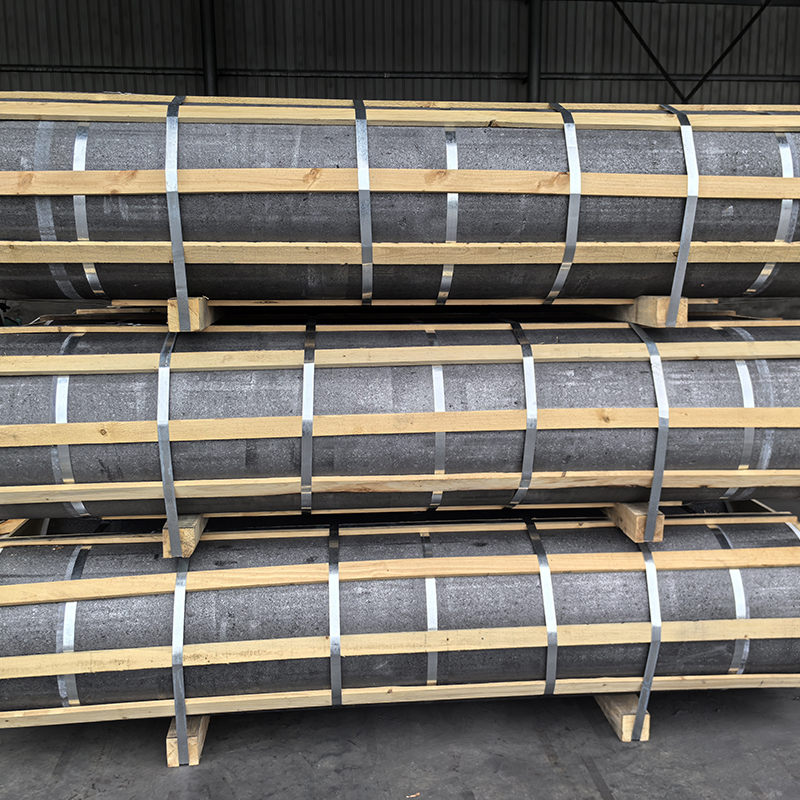

Furnace graphite electrodes are essential components in numerous high-temperature industrial processes, particularly in electric arc furnaces (EAFs) used for steelmaking. Understanding their properties, selection, and proper usage is crucial for optimizing furnace efficiency and product quality. This guide delves into the intricacies of furnace graphite electrodes, providing practical information for professionals involved in their selection and application.

Manufacturing Process of Furnace Graphite Electrodes

Raw Materials and Preparation

The production of high-quality furnace graphite electrodes begins with carefully selected raw materials, primarily petroleum coke and coal tar pitch. These materials undergo rigorous purification and processing to ensure consistent quality and performance. The precise composition and treatment of these raw materials significantly impact the final properties of the electrode.

Mixing and Forming

Once prepared, the raw materials are meticulously mixed to achieve the desired properties. This mixture is then formed into the desired electrode shape, typically cylindrical, through processes like extrusion or molding. The density and uniformity of the formed electrode are critical for its performance.

Baking and Graphitization

The formed electrodes undergo a high-temperature baking process to harden and strengthen them. Subsequently, they undergo graphitization at extremely high temperatures, transforming the amorphous carbon structure into highly crystalline graphite. This process drastically improves the electrode’s electrical conductivity and thermal shock resistance.

Machining and Finishing

After graphitization, the electrodes are machined to precise dimensions and surface finishes to ensure proper fit and function within the electric arc furnace. This final step is crucial for optimal performance and longevity.

Properties and Characteristics of Furnace Graphite Electrodes

Electrical Conductivity

High electrical conductivity is a paramount characteristic of furnace graphite electrodes. Their ability to efficiently conduct electricity is essential for the smooth operation of the electric arc furnace. The specific conductivity varies depending on the manufacturing process and the grade of the electrode. Higher grade electrodes generally exhibit superior conductivity.

Thermal Shock Resistance

Furnace graphite electrodes experience significant temperature fluctuations during operation. Resistance to thermal shock, the ability to withstand rapid temperature changes without fracturing, is therefore crucial for their longevity and reliability. The microstructure of the graphite and the manufacturing process greatly influence this property.

Mechanical Strength

The mechanical strength of the electrode is critical for withstanding the stresses and strains of operation within the furnace. This includes resistance to compression, bending, and abrasion. Strength is impacted by the density of the graphite and the overall manufacturing process.

Resistance to Oxidation

Oxidation resistance is another important property, especially at high temperatures. The rate of oxidation affects the lifespan of the electrode and the overall efficiency of the furnace. Specialized coatings and additives are sometimes utilized to improve this property.

Selection Criteria for Furnace Graphite Electrodes

Choosing the right furnace graphite electrode is crucial for optimal furnace performance. Key selection criteria include:

| Criterion | Considerations |

|---|---|

| Grade | Higher grades generally offer better properties but come at a higher cost. The specific application requirements will dictate the appropriate grade. |

| Diameter | The electrode diameter should be appropriate for the furnace size and power requirements. |

| Length | The length affects the overall efficiency and operation of the electric arc furnace. |

| Manufacturer | Choose a reputable manufacturer with a proven track record of producing high-quality electrodes. For example, consider Hebei Yaofa Carbon Co., Ltd. for their experience and expertise in the field. |

Applications of Furnace Graphite Electrodes

Furnace graphite electrodes find widespread applications in various industries, primarily in electric arc furnaces (EAFs) used for:

- Steelmaking

- Ferroalloy production

- Non-ferrous metal smelting

- Other high-temperature industrial processes

The specific type and grade of furnace graphite electrode selected will depend heavily on the specific application and its unique requirements.

This comprehensive guide provides a foundational understanding of furnace graphite electrodes. For further information and specific product inquiries, please consult relevant industry resources and manufacturers.