- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Graphite Electrode Cost: A Comprehensive Guide

2025-05-16

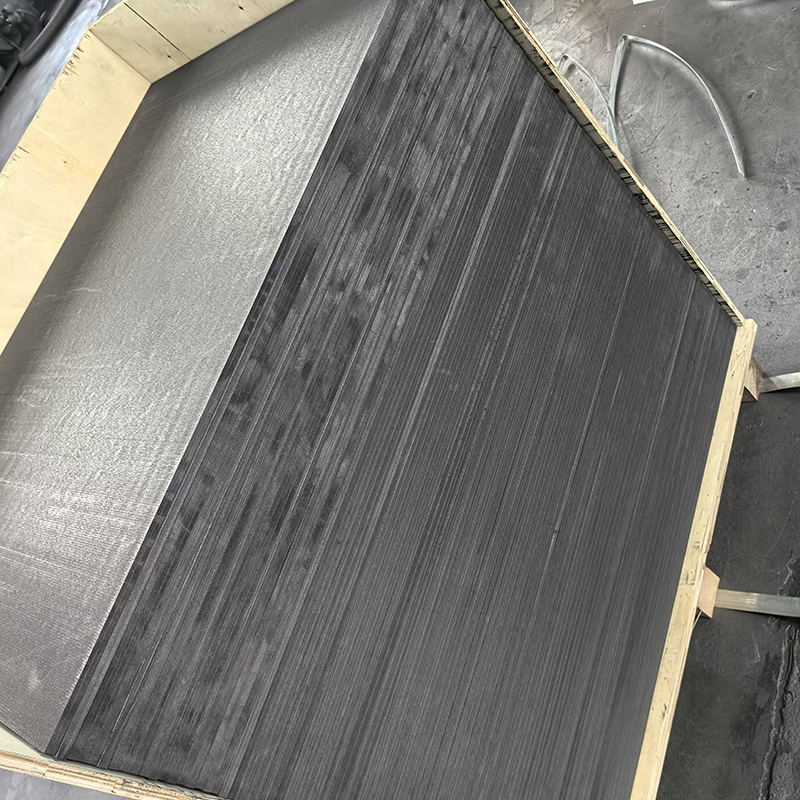

Graphite Electrode Cost: A Comprehensive Guide

This guide provides a detailed overview of graphite electrode cost, exploring factors influencing price, types of electrodes, and considerations for purchasing. Learn how to effectively manage your budget and select the optimal electrodes for your needs.

Factors Influencing Graphite Electrode Prices

Raw Material Costs

The cost of petroleum coke, the primary raw material for graphite electrodes, significantly impacts the final price. Fluctuations in global petroleum coke markets directly affect manufacturing costs and, consequently, the price of electrodes. Other factors, such as the quality and purity of the coke, also play a role.

Manufacturing Processes

The manufacturing process is complex and energy-intensive. Energy costs, labor, and equipment maintenance contribute substantially to the overall cost of production. Advancements in manufacturing technology can lead to efficiencies, but these improvements often require significant capital investment.

Electrode Specifications

The specifications of the graphite electrode, including size, grade, and quality, heavily influence price. Higher-grade electrodes, engineered for demanding applications, generally command higher prices due to their superior properties and the more stringent manufacturing processes involved. For example, ultra-high power (UHP) graphite electrodes will cost more than standard electrodes. Size also plays a major role: larger diameter electrodes tend to be more expensive to produce and transport.

Market Demand and Supply

Like any commodity, market dynamics impact graphite electrode cost. High demand coupled with limited supply can drive prices up. Conversely, oversupply can lead to price reductions. Geopolitical factors and global economic conditions can also influence market dynamics.

Transportation and Logistics

The transportation and logistics costs associated with moving graphite electrodes from the manufacturing facility to the end-user also contribute to the overall cost. These costs can vary significantly depending on the distance, mode of transportation, and packaging requirements.

Types of Graphite Electrodes and Their Costs

Graphite electrodes are categorized into different grades based on their physical and electrical properties. These grades, such as HP (high-power), UHP (ultra-high power), and RP (regular power) electrodes, differ in their purity, density, and electrical conductivity. Consequently, their prices vary considerably. UHP electrodes, due to their superior quality, typically command the highest price.

| Electrode Type | Typical Cost Range (USD/kg) | Key Features |

|---|---|---|

| RP (Regular Power) | $2.00 – $3.50 | Standard quality, suitable for general applications |

| HP (High Power) | $3.50 – $5.00 | Improved conductivity and strength, better suited for high-intensity operations |

| UHP (Ultra-High Power) | $5.00 – $7.00+ | Highest purity and performance, ideal for demanding applications |

Note: Price ranges are approximate and can vary based on several factors. Contact suppliers for current pricing information.

Tips for Managing Graphite Electrode Costs

Effective cost management involves careful planning, sourcing, and maintenance. Consider exploring options like negotiating favorable contracts with reliable suppliers, optimizing electrode consumption through efficient process control, and implementing regular maintenance schedules to prolong the lifespan of your electrodes. Partnering with a reputable supplier, such as Hebei Yaofa Carbon Co., Ltd., can provide access to competitive pricing and expert technical support.

Conclusion

Understanding the factors that influence graphite electrode cost is crucial for effective budget management and procurement. By considering the electrode type, specifications, market dynamics, and supplier relationships, businesses can make informed decisions to optimize their operations and minimize expenses.