- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Graphite Electrode Price: A Comprehensive Guide

2025-04-25

Graphite Electrode Price: A Comprehensive Guide

This guide provides a comprehensive overview of graphite electrode price factors, influencing market trends, and considerations for buyers. Learn about different types of graphite electrodes, their applications, and how to find reliable suppliers. We’ll explore the key factors affecting pricing and offer insights to help you make informed purchasing decisions.

Factors Influencing Graphite Electrode Prices

Raw Material Costs

The price of graphite electrodes is heavily influenced by the cost of raw materials, primarily petroleum coke and needle coke. Fluctuations in global energy prices and the availability of these cokes directly impact the manufacturing cost and, consequently, the final graphite electrode price. Increases in raw material costs often lead to higher electrode prices.

Manufacturing Processes and Technology

The manufacturing process for graphite electrodes is complex and energy-intensive. Advances in technology and efficiency improvements can influence the overall cost. Companies investing in modern, efficient manufacturing processes may be able to offer more competitive graphite electrode prices. However, initial investments in advanced technology can also drive up costs in the short term.

Market Demand and Supply

Like any commodity, the interplay of supply and demand significantly impacts graphite electrode prices. High demand, particularly from the steel industry, coupled with limited supply can lead to price increases. Conversely, lower demand or increased production capacity can result in lower prices. Global economic conditions and the growth of key industries consuming graphite electrodes are crucial factors.

Global Economic Conditions

Macroeconomic factors, such as inflation, currency exchange rates, and geopolitical events, can significantly impact graphite electrode prices. Economic downturns can reduce demand and lead to price reductions, while periods of strong economic growth can drive up prices. These external factors are often difficult to predict and can create market volatility.

Transportation and Logistics

The transportation and logistics involved in getting graphite electrodes from the manufacturer to the end-user also contribute to the final price. Fuel costs, shipping distances, and logistical complexities can all add to the overall cost.

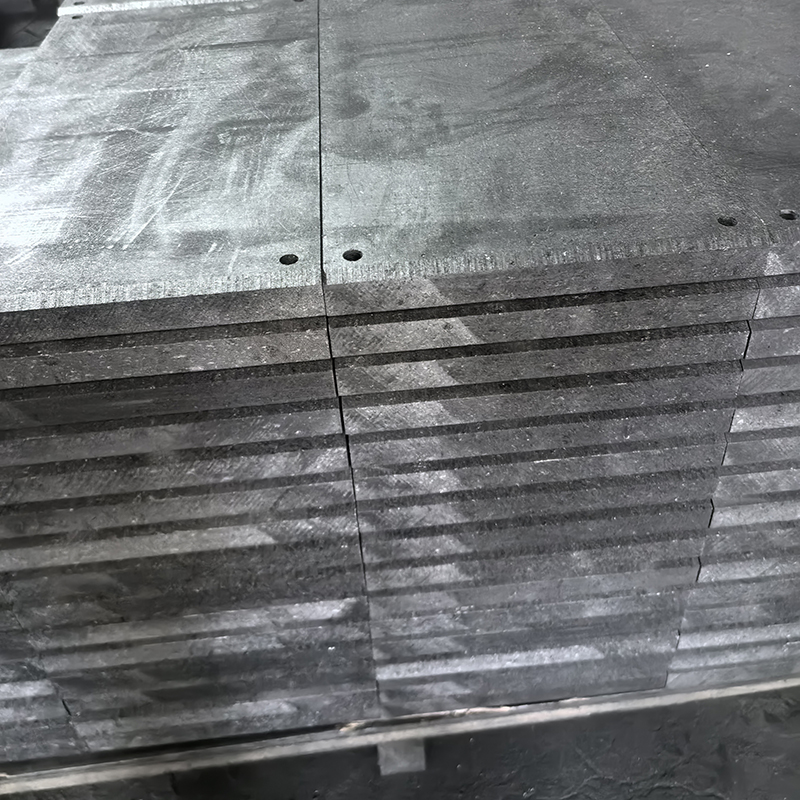

Types of Graphite Electrodes and Their Applications

Graphite electrodes come in various sizes and grades, each suited for specific applications. The type of electrode needed impacts the graphite electrode price. High-quality electrodes, designed for demanding applications, typically command higher prices.

RP (Regular Packed) Graphite Electrodes

These are widely used in various applications due to their balance of performance and cost.

HP (High-Packed) Graphite Electrodes

These electrodes offer superior properties, resulting in a higher graphite electrode price but also greater efficiency and longer service life.

Finding Reliable Suppliers

Choosing a reliable supplier is crucial for securing quality graphite electrodes at competitive prices. Consider factors like supplier reputation, manufacturing capabilities, and after-sales service. Conduct thorough research and request quotes from multiple suppliers before making a purchase decision. For high-quality graphite electrodes and excellent customer service, consider contacting Hebei Yaofa Carbon Co., Ltd., a leading manufacturer in the industry.

Price Trends and Forecasting

Predicting future graphite electrode prices is challenging due to the many variables involved. However, by monitoring raw material costs, market demand, and global economic conditions, you can gain a better understanding of potential price fluctuations. Consulting industry reports and market analyses can provide additional insights.

Conclusion

Understanding the factors influencing graphite electrode prices is essential for informed purchasing decisions. By considering the various aspects discussed above, buyers can navigate the market effectively and secure the best possible value for their needs. Remember to always prioritize quality and reliability when selecting a supplier.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}