- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Graphite Electrode Tongs: A Comprehensive Guide

2025-07-08

Graphite Electrode Tongs: A Comprehensive Guide

This guide provides a detailed overview of graphite electrode tongs, covering their types, applications, safety considerations, and selection criteria. We explore the crucial factors to consider when choosing the right tongs for your specific needs, ensuring efficient and safe handling of graphite electrodes in various industrial settings. Learn about the different designs, materials, and functionalities available to optimize your operations.

Understanding Graphite Electrode Tongs

What are Graphite Electrode Tongs?

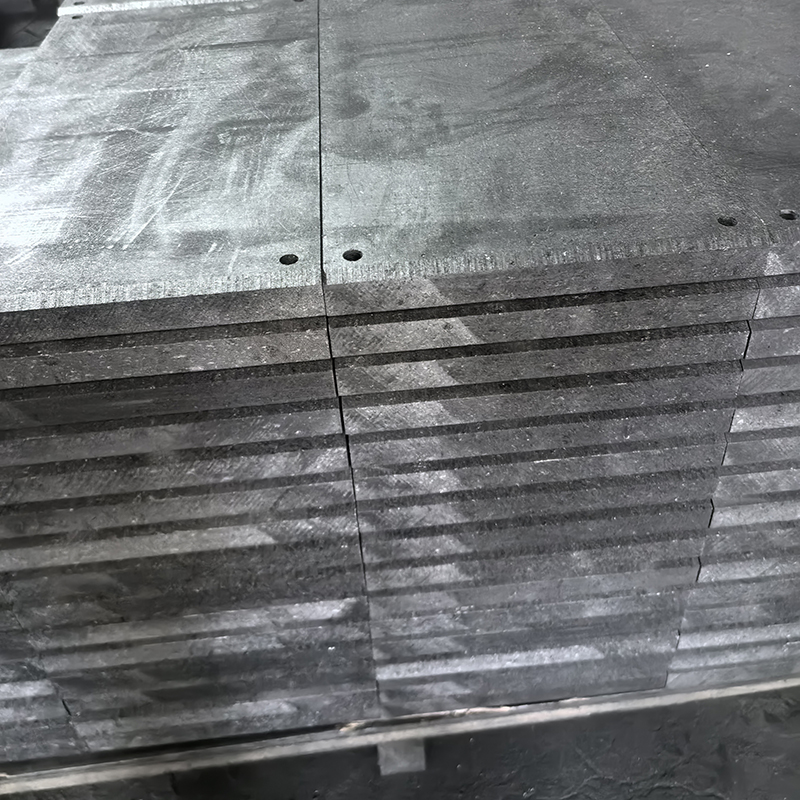

Graphite electrode tongs are specialized tools designed to safely grip and manipulate graphite electrodes during various industrial processes. These electrodes are commonly used in electric arc furnaces (EAFs) for steelmaking, and other high-temperature applications. The tongs are engineered to withstand extreme temperatures and provide a secure grip, preventing accidents and ensuring efficient electrode handling.

Types of Graphite Electrode Tongs

Several types of graphite electrode tongs exist, each designed for specific electrode sizes and applications. Common types include:

- Hydraulic graphite electrode tongs: These tongs utilize hydraulic power for precise and powerful gripping, suitable for larger and heavier electrodes.

- Pneumatic graphite electrode tongs: Pneumatic tongs use compressed air for operation, offering a good balance of power and speed.

- Manual graphite electrode tongs: These are simpler tongs operated manually, typically used for smaller electrodes or less demanding applications. However, caution must be exercised due to the potential for burns or injury.

Key Features and Considerations

When selecting graphite electrode tongs, several key features must be considered:

- Electrode Size Compatibility: Ensure the tongs are rated for the specific size and weight of the electrodes you handle.

- Grip Strength and Stability: The tongs should provide a secure and stable grip, even at high temperatures.

- Material and Durability: The material should withstand extreme temperatures and resist wear and tear. High-quality materials like forged steel are common.

- Safety Features: Features like thermal insulation and ergonomic design are crucial for operator safety.

- Maintenance Requirements: Consider the ease of maintenance and the availability of spare parts.

Selecting the Right Graphite Electrode Tongs

Factors Influencing Your Choice

The selection of appropriate graphite electrode tongs depends on several factors including:

- The size and weight of the graphite electrodes.

- The operating environment (temperature, dust, etc.).

- The required gripping force and precision.

- The budget and maintenance capabilities.

Comparison of Different Tong Types

| Type | Advantages | Disadvantages |

|---|---|---|

| Hydraulic | High gripping force, precise control | More complex, higher cost |

| Pneumatic | Faster operation, relatively low cost | May not provide as much gripping force as hydraulic |

| Manual | Simplest and cheapest option | Requires significant manual effort, safety concerns |

Safety Precautions When Using Graphite Electrode Tongs

Essential Safety Measures

Always prioritize safety when handling graphite electrodes and using graphite electrode tongs. Follow these safety measures:

- Wear appropriate personal protective equipment (PPE), including heat-resistant gloves, safety glasses, and protective clothing.

- Ensure proper training before operating the tongs.

- Regularly inspect the tongs for any damage or wear and tear.

- Follow the manufacturer’s instructions for operation and maintenance.

- Never attempt to operate damaged tongs.

Where to Find High-Quality Graphite Electrode Tongs

For high-quality graphite electrode tongs and other carbon products, consider contacting a reputable manufacturer such as Hebei Yaofa Carbon Co., Ltd.. They offer a wide range of products for various industrial applications.

Note: This information is for general guidance only. Always consult the manufacturer’s specifications and safety instructions before using any graphite electrode tongs or equipment. Specific safety requirements may vary depending on the application and local regulations.