- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Graphite Electrodes: Uses and Applications in Various Industries

2025-05-26

Graphite Electrodes: Uses and Applications in Various Industries

This comprehensive guide explores the diverse applications of graphite electrodes across various industries. We delve into the properties that make them ideal for specific processes, examining their functionality and benefits in detail. Learn about the different types of graphite electrodes available and discover how they contribute to efficient and effective industrial operations.

Understanding Graphite Electrodes

What are Graphite Electrodes?

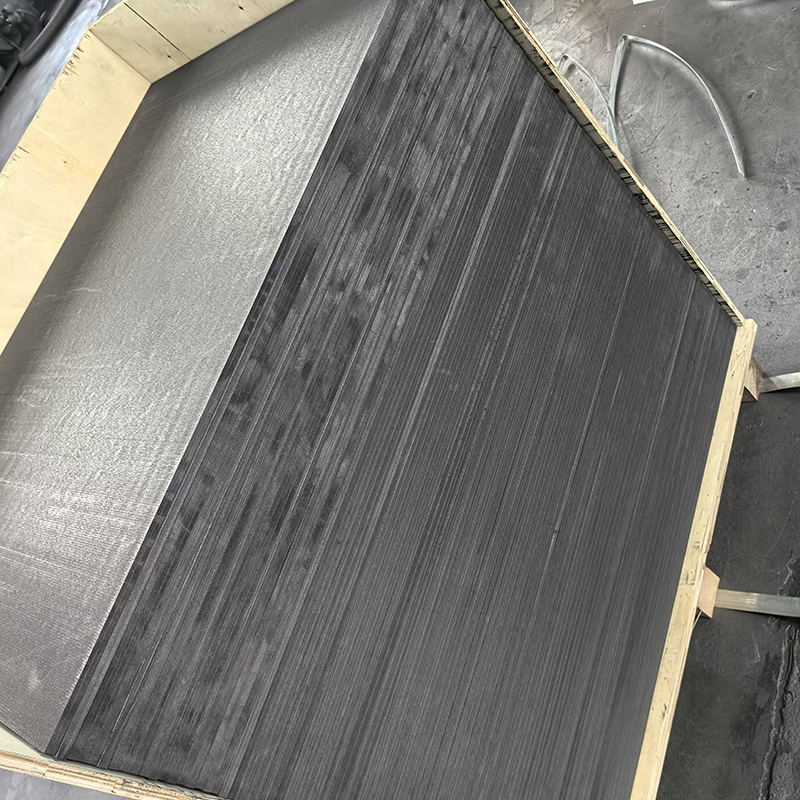

Graphite electrodes are crucial components in numerous industrial processes, particularly in the metallurgical and chemical sectors. They are manufactured from high-purity graphite, a form of carbon known for its exceptional electrical conductivity, high thermal shock resistance, and chemical inertness. These properties make them ideal for use as conductors of electricity in high-temperature environments where other materials would fail. The manufacturing process often involves careful selection of raw materials and sophisticated processing techniques to ensure the desired quality and performance.

Key Properties of Graphite Electrodes

The effectiveness of graphite electrodes stems from their unique combination of properties:

- High Electrical Conductivity: Enables efficient transfer of electrical current.

- Excellent Thermal Conductivity: Facilitates heat dissipation and prevents overheating.

- High Thermal Shock Resistance: Withstands rapid temperature changes without fracturing.

- Chemical Inertness: Resists corrosion and degradation in harsh environments.

- High Strength: Able to withstand the physical stresses of industrial processes.

Applications of Graphite Electrodes

Electrometallurgy

The most prominent use of graphite electrodes is in electrometallurgy, specifically in the production of metals like aluminum, steel, and ferroalloys. They serve as anodes in electrolytic cells, facilitating the reduction of metal oxides to their pure metallic forms. The choice of electrode type (e.g., HPGR, UHPGR) depends on the specific application and the required purity of the final product. High-purity graphite electrodes are often preferred for demanding applications due to their superior performance and longer lifespan. Hebei Yaofa Carbon Co., Ltd. is a leading manufacturer of high-quality graphite electrodes for electrometallurgical processes.

Electric Arc Furnaces (EAFs)

In Electric Arc Furnaces (EAFs), graphite electrodes are used to generate the intense heat needed to melt and refine steel scrap. The electrodes are consumed during the process, requiring regular replacement. The selection of appropriate graphite electrodes is crucial to optimize energy efficiency and minimize operating costs. Factors such as electrode diameter, length, and grade influence the performance in EAF applications.

Other Industries

Beyond electrometallurgy, graphite electrodes find applications in:

- Chemical Processing: Used in electrochemical processes such as chlorine production and metal plating.

- Water Treatment: Used in electrochemical oxidation processes for water purification.

- Solar Energy: Employed in the manufacturing of solar cells.

Choosing the Right Graphite Electrode

Selecting the correct graphite electrode depends on several factors:

- Application Requirements: The specific industrial process and its demands.

- Current Requirements: The level of electrical current that needs to be conducted.

- Operating Temperature: The temperature range the electrode will be subjected to.

- Electrode Size and Shape: Dimensions appropriate for the equipment used.

- Budgetary Constraints: Balancing cost and performance considerations.

Conclusion

Graphite electrodes are indispensable components in a wide array of industrial applications. Their unique properties make them crucial for efficient and effective processes across various sectors. Understanding the properties and choosing the appropriate type is essential for optimal performance and cost-effectiveness.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}