- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

High-Performance Graphite Electrodes: A Comprehensive Guide

2025-05-11

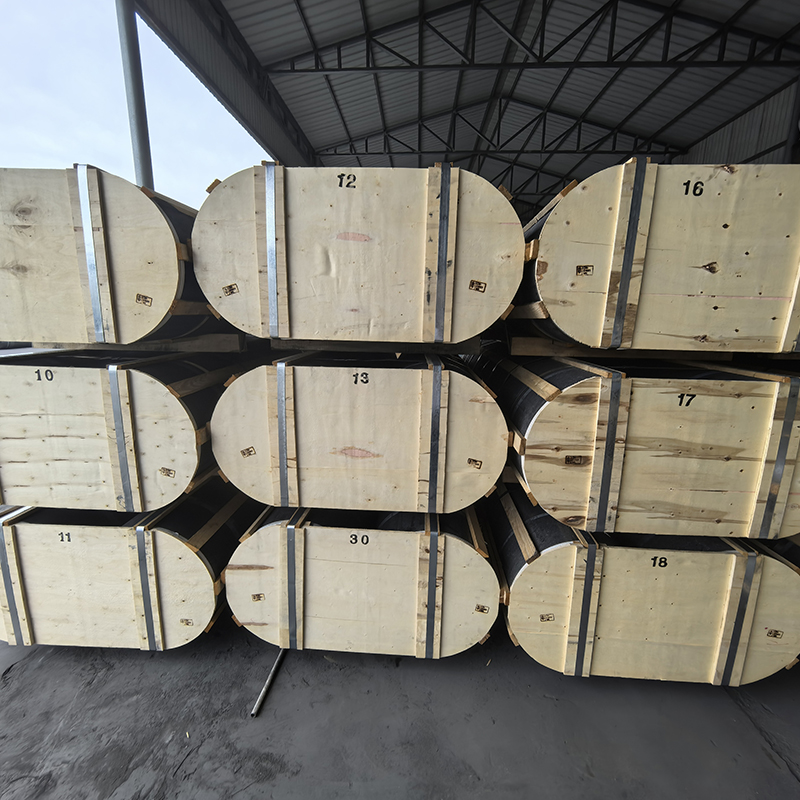

High-Performance Graphite Electrodes: A Comprehensive Guide

This guide provides a detailed overview of graphite electrodes, covering their properties, applications, manufacturing processes, and selection criteria. Learn about the different types of electrodes en graphite available, their advantages and disadvantages, and how to choose the right electrode for your specific needs. We’ll explore key factors to consider when selecting graphite electrodes for optimal performance in various industries.

Understanding Graphite Electrodes

What are Graphite Electrodes?

Graphite electrodes are essential components used in numerous industrial processes, primarily those involving high-temperature applications and electrical conductivity. They are manufactured from high-purity graphite, a form of carbon with exceptional properties, including excellent electrical conductivity, high thermal shock resistance, and chemical inertness. The quality and performance of a graphite electrode depend heavily on the raw materials and the manufacturing process employed. Different grades exist, tailored to specific applications.

Types of Graphite Electrodes

Graphite electrodes are categorized based on several factors, including their grade, size, and shape. Common types include:

- High-power electrodes en graphite: Designed for high-current applications, offering superior conductivity and durability.

- Ultra-high-power graphite electrodes: These electrodes are engineered for the most demanding applications requiring exceptional current carrying capacity and resistance to erosion.

- Standard-power electrodes en graphite: Providing a balance between performance and cost, suitable for a wide range of applications.

The choice depends heavily on the specific needs of the application. For example, electric arc furnaces often utilize high-power or ultra-high-power electrodes en graphite to handle the immense currents involved.

Applications of Graphite Electrodes

Key Industries Utilizing Graphite Electrodes

The versatility of graphite electrodes makes them indispensable in various industries. Their prominent applications include:

- Steelmaking: A significant application lies in electric arc furnaces (EAFs) where electrodes en graphite are crucial for melting and refining steel. The quality and performance of the graphite electrodes directly impact the efficiency and output of the steelmaking process.

- Aluminum Production: The electrolytic production of aluminum utilizes large-scale graphite electrodes for the efficient transfer of electrical current.

- Other Industrial Processes: Graphite electrodes also find use in other high-temperature processes, such as the production of ferroalloys, silicon carbide, and other advanced materials.

Selecting the Right Graphite Electrodes

Factors to Consider

Choosing the appropriate electrodes en graphite requires careful consideration of several factors:

- Current carrying capacity: This is crucial for determining the electrode’s suitability for a specific application. Higher currents demand electrodes with greater conductivity.

- Resistance to thermal shock: The electrode must withstand rapid temperature changes without fracturing or cracking.

- Chemical inertness: The electrode’s resistance to chemical attack from the molten materials is essential for prolonged lifespan.

- Size and shape: The physical dimensions of the electrode must match the requirements of the application.

Manufacturing Process and Quality Control

The manufacturing process for graphite electrodes involves several critical steps, ensuring high-quality products. Strict quality control measures are implemented throughout the process, from raw material selection to final inspection. Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) is a leading manufacturer of high-performance graphite electrodes, renowned for its commitment to quality and innovation. Their expertise ensures the production of consistent, high-performing electrodes en graphite for various industries.

Conclusion

Graphite electrodes are crucial components in many high-temperature industrial processes. Understanding their properties, applications, and selection criteria is vital for ensuring efficient and cost-effective operations. By considering factors like current carrying capacity, thermal shock resistance, and chemical inertness, businesses can choose the optimal electrodes en graphite to meet their specific requirements. Choosing a reputable supplier like Hebei Yaofa Carbon Co., Ltd. ensures access to high-quality graphite electrodes and expert support.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}