- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

High-Performance Graphite Electrodes for Electrolysis: A Comprehensive Guide

2025-05-17

High-Performance Graphite Electrodes for Electrolysis: A Comprehensive Guide

This guide provides a detailed overview of graphite electrodes used in electrolysis, exploring their properties, applications, selection criteria, and considerations for optimal performance. We delve into the critical factors influencing their effectiveness and longevity in various electrolytic processes. Learn how to choose the right electrode for your specific needs and maximize your process efficiency.

Understanding Graphite Electrodes in Electrolysis

What are Graphite Electrodes?

Graphite electrodes are crucial components in electrolytic cells. Their high electrical conductivity, chemical resistance, and thermal stability make them ideal for facilitating the flow of current and resisting degradation during the electrochemical reactions involved in electrolysis. Different grades of graphite offer varying properties, influencing their suitability for specific applications. For example, high-density graphite electrodes demonstrate superior performance in demanding electrolysis processes.

Types of Graphite Electrodes for Electrolysis

Several types of graphite electrodes are available, each tailored for specific applications. These include isostatic graphite electrodes, which offer excellent dimensional stability and are often used in high-temperature electrolysis. Other types include molded graphite and coated graphite electrodes, each with unique advantages. The choice depends heavily on the specific electrolytic process and the operating conditions.

Factors Affecting Graphite Electrode Performance

Electrical Conductivity

The electrical conductivity of the graphite electrode directly impacts energy efficiency. High conductivity minimizes energy loss during current transfer, leading to better overall process economics. The specific conductivity value depends on the grade of graphite and its processing methods. The higher the conductivity, the better the electrode performance. Furthermore, the electrode design also impacts conductivity, with uniform current distribution improving efficiency.

Chemical Resistance and Corrosion

Electrolytic processes often involve corrosive electrolytes. The chemical resistance of the graphite electrode is paramount to prevent its degradation and maintain performance. Different graphite grades exhibit varying levels of resistance to specific chemicals. Choosing an electrode with adequate resistance to the electrolyte used is crucial for longevity.

Thermal Stability

Electrolysis can generate significant heat. The thermal stability of the graphite electrode ensures it can withstand these temperatures without structural damage or performance deterioration. This is especially important in high-temperature electrolysis processes where electrode failure can be catastrophic.

Selecting the Right Graphite Electrode

Selecting the appropriate graphite electrode involves considering several factors:

| Factor | Considerations |

|---|---|

| Electrolyte Type | Chemical compatibility and corrosion resistance are crucial. |

| Operating Temperature | Thermal stability and dimensional stability are key at elevated temperatures. |

| Current Density | High current densities necessitate electrodes with superior conductivity. |

| Electrode Size and Shape | Optimal design for uniform current distribution and minimizing energy losses. |

Leading Supplier of High-Quality Graphite Electrodes

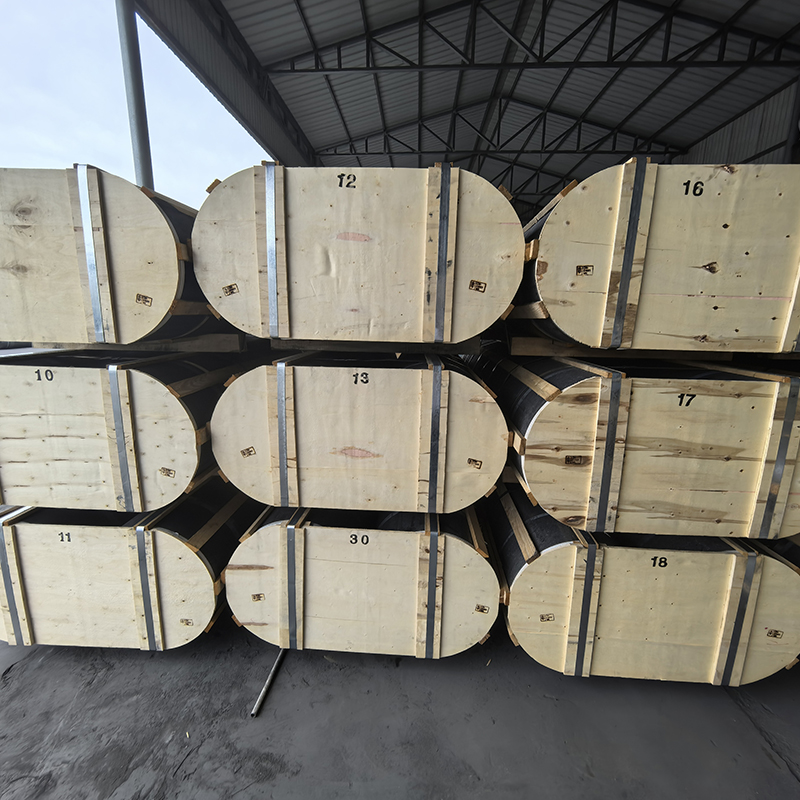

For high-quality graphite electrodes designed for optimal performance in electrolysis, consider Hebei Yaofa Carbon Co., Ltd.. They offer a wide range of electrodes tailored to diverse applications, ensuring efficient and reliable operation in your electrolytic processes. Their expertise and commitment to quality make them a trusted partner for your electrolysis needs.

1 Data on specific graphite electrode properties can be obtained from the manufacturers’ technical specifications. Consult Hebei Yaofa Carbon Co., Ltd. for detailed information on their product offerings.