- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

How innovative are Graftech electrodes?

2025-06-22

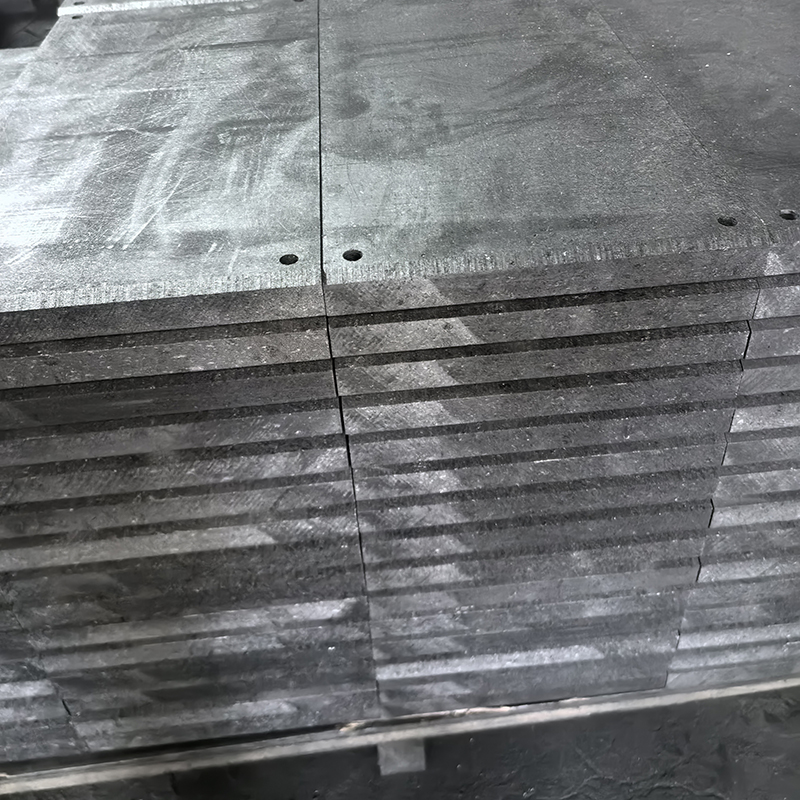

Graftech Electrodes: A Comprehensive GuideGraftech electrodes are high-quality graphite components crucial for various industrial processes. This article provides a comprehensive overview of Graftech electrodes, exploring their applications, benefits, and key considerations for selection and use. We’ll delve into different types, sizes, and specifications, ensuring you have the knowledge to make informed decisions for your specific needs.

Understanding Graftech Electrodes

What are Graftech Electrodes?

Graftech electrodes are manufactured from high-purity graphite, renowned for its exceptional electrical conductivity, thermal shock resistance, and high operating temperatures. This makes them ideal for demanding applications where superior performance and reliability are critical. The company, Graftech, is a leading global supplier of advanced materials, and their electrodes are widely recognized for their consistent quality and performance. Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) also offers a range of high-quality carbon products that may be suitable alternatives or complementary to Graftech electrodes depending on your specific requirements.

Types and Applications of Graftech Electrodes

Graftech electrodes come in a variety of shapes and sizes, tailored to specific applications. These include: High-Power Electrodes: Designed for applications requiring high current densities and exceptional thermal stability. These are often used in demanding industrial furnaces and electrolytic processes. Ultra-High-Purity Electrodes: Essential where contamination must be minimized, such as in the semiconductor and solar industries. Specialty Electrodes: Custom-designed electrodes for unique applications, often involving specialized shapes or materials.These electrodes find extensive use in industries such as: Aluminum Smelting: Graftech electrodes are a critical component in the Hall-Héroult process for aluminum production. Their durability and high conductivity contribute significantly to the efficiency and longevity of the smelting process. Steelmaking: Used in electric arc furnaces (EAFs) for steel production, Graftech electrodes contribute to efficient and cost-effective steel manufacturing. Other Industrial Applications: Beyond aluminum and steel production, Graftech electrodes are applied in various other industrial processes, including the production of silicon, ferroalloys, and other metallurgical applications.

Choosing the Right Graftech Electrode

Selecting the appropriate Graftech electrode necessitates considering several crucial factors:

Key Selection Criteria

Electrical Conductivity: A critical parameter determining the efficiency of the process. Higher conductivity translates to less energy consumption and improved overall performance. Thermal Shock Resistance: Essential for applications involving frequent temperature fluctuations. High resistance prevents cracking or damage due to thermal stress. Size and Shape: The electrode dimensions must be carefully selected to ensure compatibility with the equipment and process requirements. Purity: The level of purity required depends on the application. Ultra-high purity is needed in some processes to avoid contamination.

Specifications and Data Sheets

Detailed specifications and data sheets are available from Graftech for each electrode type. These documents provide essential information, including dimensions, material properties, and performance characteristics. Always consult these documents before making a purchase to ensure compatibility with your specific application and requirements.

Maintenance and Handling of Graftech Electrodes

Proper handling and maintenance extend the lifespan and performance of Graftech electrodes.

Best Practices for Handling

Avoid dropping or impacting the electrodes. Store them in a dry place to prevent moisture absorption. Inspect electrodes regularly for any signs of damage or wear.

Troubleshooting Common Issues

Premature wear: This could indicate improper handling, incorrect operating parameters, or electrode material incompatibility. Electrode breakage: Check for flaws in the electrode material or excessive thermal stress.

Conclusion

Graftech electrodes are high-performance components essential for various industrial applications. Careful consideration of their various types, specifications, and application requirements is crucial for achieving optimal efficiency and performance. By understanding the key selection criteria and employing proper handling and maintenance practices, users can ensure the longevity and effectiveness of their Graftech electrodes in their operations. Remember to consult the official Graftech documentation for detailed specifications and further information.table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}