- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

How’s graphite electrode tech evolving?

2025-04-25

Graphite Electrodes: A Comprehensive GuideUnderstanding the role of graphite electrodes in various industries is crucial for anyone involved in manufacturing, materials science, or related fields. This guide provides an in-depth exploration of graphite electrodes, covering their properties, applications, manufacturing processes, and considerations for selection and maintenance.

What are Graphite Electrodes?

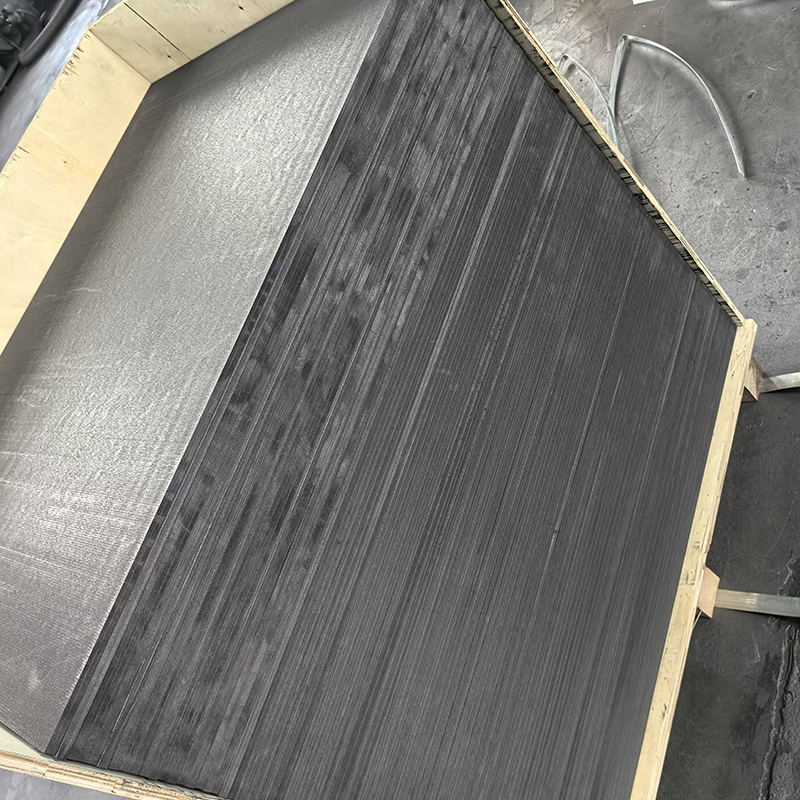

Graphite electrodes are essential components used in numerous industrial processes, primarily in electric arc furnaces (EAFs) for steelmaking and other high-temperature applications. They are manufactured from high-quality graphite, a form of carbon known for its exceptional electrical conductivity, high thermal shock resistance, and resistance to corrosion. The precise properties of a graphite electrode depend heavily on the manufacturing process and the raw materials used. Understanding these variations is key to selecting the right electrode for a specific application.

Types and Properties of Graphite Electrodes

Different Grades of Graphite Electrodes

Graphite electrodes are available in various grades, each tailored to specific needs. These grades are classified based on their properties, such as density, electrical resistivity, and mechanical strength. Choosing the appropriate grade is crucial for optimizing performance and extending electrode lifespan. For example, high-power applications often benefit from high-density electrodes, while applications demanding high thermal shock resistance may require electrodes with specific formulations.

Key Properties and Their Significance

The success of any process relying on graphite electrodes hinges on understanding their key properties. These include:

- Electrical Conductivity: The ability to efficiently conduct electricity is paramount. Higher conductivity leads to reduced energy consumption and improved efficiency in EAFs.

- Thermal Conductivity: Efficient heat transfer is crucial, especially in high-temperature environments. A good thermal conductivity minimizes localized heating and prolongs electrode life.

- Mechanical Strength: Electrodes must withstand significant physical stresses during operation. High mechanical strength reduces breakage and ensures consistent performance.

- Thermal Shock Resistance: The ability to withstand rapid temperature changes is vital in applications with fluctuating heat loads. Superior resistance minimizes cracking and extends service life.

Applications of Graphite Electrodes

Steelmaking and Metal Production

The most prevalent use of graphite electrodes is in steelmaking within EAFs. They are used to create the electric arc necessary to melt scrap metal and produce steel. The choice of electrode grade significantly impacts the energy efficiency and overall productivity of the steelmaking process. Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) is a leading manufacturer of high-quality graphite electrodes for this critical application.

Other Industrial Applications

Beyond steelmaking, graphite electrodes find use in various other high-temperature applications, such as:

- Aluminum smelting

- Ferroalloy production

- Silicon carbide production

- Electrochemical processes

Selection and Maintenance of Graphite Electrodes

Proper selection and maintenance are vital for maximizing the performance and lifespan of graphite electrodes. Factors to consider include the specific application requirements, operating conditions, and the desired electrode life. Regular inspection for signs of wear and tear, proper handling, and appropriate storage procedures all contribute to extended electrode service life. Consulting with experienced suppliers like Hebei Yaofa Carbon Co., Ltd. can provide valuable insights into best practices.

Comparison of Graphite Electrode Grades

| Grade | Density (g/cm3) | Resistivity (μΩ·cm) | Tensile Strength (MPa) |

|---|---|---|---|

| HP Grade | 1.75 | 7.5 | 8 |

| RP Grade | 1.70 | 8.0 | 7 |

Note: These are example values and can vary based on manufacturer and specific product specifications. Consult the manufacturer’s data sheets for precise values.

This information is for general guidance only and should not be considered professional advice. Always consult with experts and relevant safety guidelines before handling or working with graphite electrodes.