- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Is RP graphite electrode power sustainable?

2025-06-14

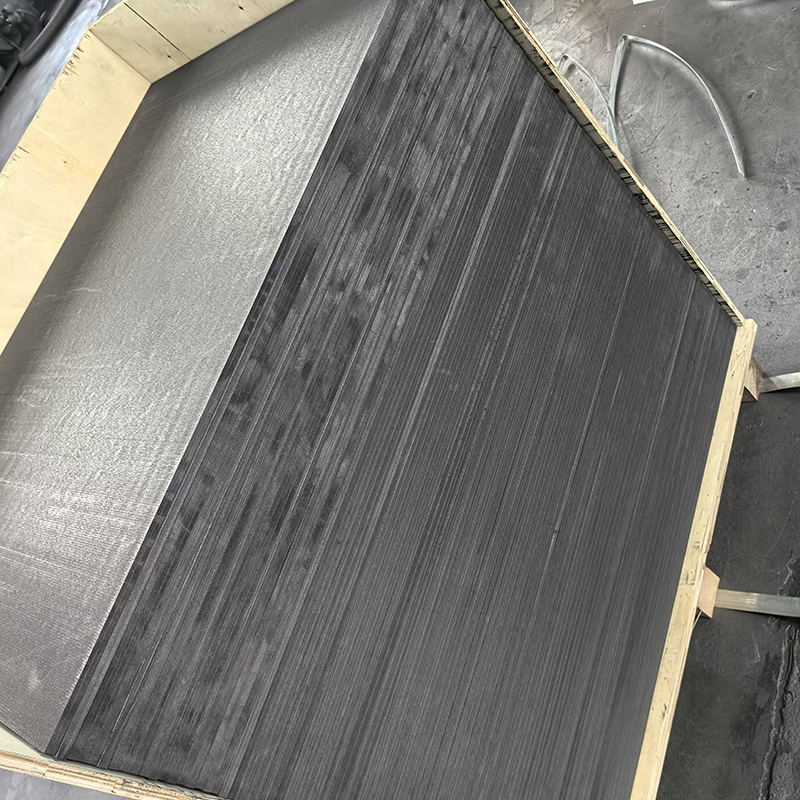

RP Normal Power Graphite Electrodes: A Comprehensive GuideRP normal power graphite electrodes are a crucial component in numerous industrial processes, particularly in electric arc furnaces (EAFs) used for steelmaking. This guide provides a comprehensive overview of their properties, applications, and selection considerations.

Understanding RP Normal Power Graphite Electrodes

RP normal power graphite electrodes are manufactured using high-quality petroleum coke and pitch. The manufacturing process involves careful control of temperature and pressure to achieve the desired density and electrical conductivity. These electrodes are characterized by their relatively high resistance to oxidation and their ability to withstand the high temperatures and currents encountered in EAF operations. The ‘RP’ designation often refers to a specific grade or manufacturer’s specification, indicating properties like resistivity and strength. Understanding these specifications is vital for selecting the optimal electrode for a particular application.

Key Properties and Specifications

Several key properties determine the suitability of a RP normal power graphite electrode for a specific application. These include:

- Electrical Resistivity: This determines the efficiency of current transfer and heat generation.

- Mechanical Strength: Crucial for withstanding the physical stresses during operation.

- Thermal Shock Resistance: The ability to resist damage from rapid temperature changes.

- Oxidation Resistance: Important for maintaining electrode longevity.

- Density: Affects the electrode’s overall performance and durability.

These specifications are often detailed in the manufacturer’s datasheets, ensuring users can choose the correct electrode for their needs. For precise specifications, consult the Hebei Yaofa Carbon Co., Ltd. website, a leading supplier of high-quality graphite electrodes.

Applications of RP Normal Power Graphite Electrodes

The primary application of RP normal power graphite electrodes is in electric arc furnaces (EAFs) used for steelmaking. Their ability to efficiently conduct electricity and withstand high temperatures makes them indispensable in this process. Beyond steelmaking, these electrodes find applications in other high-temperature industrial processes, including:

- Ferroalloy production

- Silicon carbide production

- Aluminum smelting (although specialized electrodes are often preferred)

Selecting the Right RP Normal Power Graphite Electrode

Choosing the appropriate RP normal power graphite electrode requires careful consideration of several factors. These include the specific application, the operating conditions (temperature, current, etc.), and the desired electrode life. It’s crucial to consult with experienced professionals and manufacturers to ensure compatibility and optimal performance.

Comparison of RP Normal Power Graphite Electrodes with Other Types

While RP normal power graphite electrodes are widely used, other types of graphite electrodes, such as high-power and ultra-high-power electrodes, are available, each with its own strengths and weaknesses. The choice depends heavily on the specific demands of the application.

| Electrode Type | Power Level | Typical Applications |

|---|---|---|

| RP Normal Power | Medium | General steelmaking, some ferroalloy production |

| High-Power | High | High-intensity steelmaking, specialized applications |

| Ultra-High-Power | Very High | Extremely demanding applications, requiring high current density |

For detailed information on different types and specifications, visit the Hebei Yaofa Carbon Co., Ltd. website.

Conclusion

RP normal power graphite electrodes play a vital role in various industrial processes, particularly steelmaking. Understanding their properties, applications, and selection criteria is crucial for ensuring optimal performance and efficiency. Careful consideration of the specific application requirements and consultation with experienced professionals will lead to the best selection of graphite electrodes for your needs.