- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

RP Graphite Electrodes: A Comprehensive Guide

2025-06-28

RP Graphite Electrodes: A Comprehensive GuideThis article provides a detailed overview of RP graphite electrodes, covering their properties, applications, manufacturing process, and market trends. Learn about the different types of RP graphite electrodes, their advantages and disadvantages, and how to choose the right electrode for your specific needs. We’ll also explore the future of this crucial material in various industries.

RP Graphite Electrodes: A Comprehensive Guide

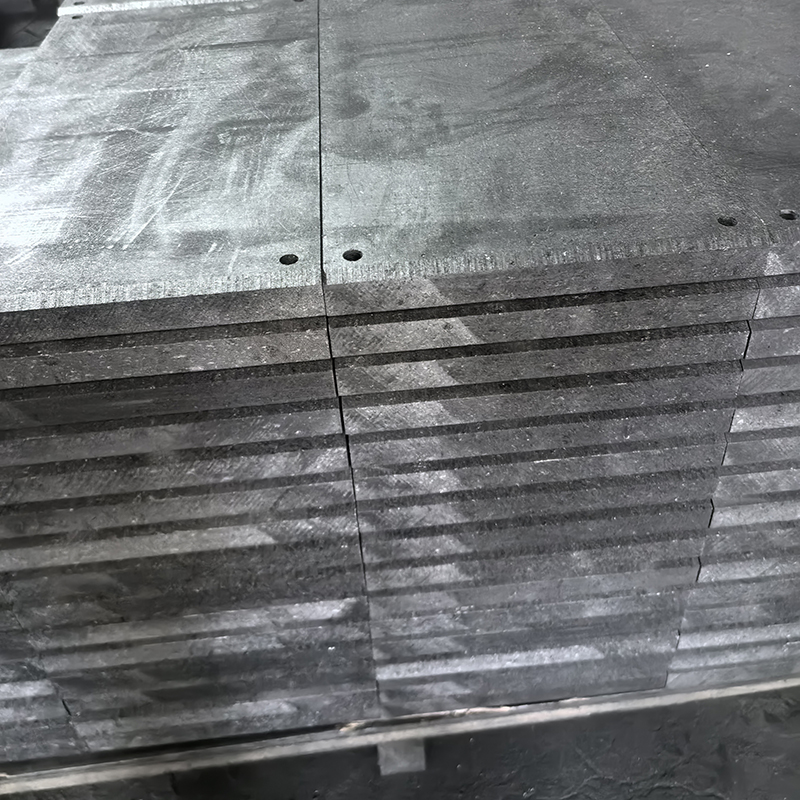

RP graphite electrodes are high-quality, high-performance electrodes used in various industries, primarily in electric arc furnaces (EAFs) for steelmaking. Their exceptional properties make them crucial for efficient and cost-effective steel production. This guide explores the intricacies of RP graphite electrodes, delving into their composition, manufacturing, applications, and market dynamics.

Understanding RP Graphite Electrodes

RP stands for Regular Petroleum coke, indicating the type of coke used in the manufacturing process. This type of coke contributes significantly to the electrodes’ superior properties. The key characteristics of RP graphite electrodes include high electrical conductivity, high thermal shock resistance, and exceptional mechanical strength. These features allow for efficient energy transfer and prolonged electrode lifespan, ultimately improving the efficiency and reducing the operating costs of EAFs.

Composition and Properties

RP graphite electrodes are primarily composed of high-quality graphite, derived from petroleum coke. The manufacturing process involves careful selection of raw materials and precise control over various parameters to achieve the desired properties. The resulting electrodes exhibit high purity, contributing to their superior performance. Specific properties, such as density, electrical resistivity, and thermal conductivity, are tailored to meet the demands of different applications.

Manufacturing Process

The creation of RP graphite electrodes is a complex multi-stage process. It begins with the careful selection and blending of petroleum coke, followed by calcining and graphitization processes under controlled temperatures and pressures. This process transforms the raw materials into high-density, high-strength graphite. Finally, the graphite is machined to the precise dimensions required for different applications. The entire process requires advanced technology and skilled personnel to ensure consistent quality and performance.

Applications of RP Graphite Electrodes

The primary application of RP graphite electrodes is in the steel industry, specifically in electric arc furnaces (EAFs). They act as the conduit for the electric current needed to melt scrap metal, facilitating steel production. However, their uses extend beyond steelmaking. They are also employed in other industries requiring high-performance electrical components, such as:

- Aluminum smelting

- Silicon production

- Other metallurgical processes

Choosing the Right RP Graphite Electrode

Selecting the appropriate RP graphite electrode depends on several factors, including the specific application, power requirements, and desired operating conditions. Key considerations include electrode diameter, length, and the overall quality of the graphite. Consulting with a supplier specializing in RP graphite electrodes is recommended to ensure optimal performance and cost-effectiveness.

Market Trends and Future Outlook

The market for RP graphite electrodes is experiencing significant growth, driven primarily by the expanding steel industry, particularly in emerging economies. Advancements in manufacturing technologies and ongoing research and development efforts are leading to the creation of even higher-performance electrodes with improved efficiency and longer lifespans. This continued innovation promises to enhance the cost-effectiveness and sustainability of various industrial processes.

Contact Us

For high-quality RP graphite electrodes and expert consultation, contact Hebei Yaofa Carbon Co., Ltd., a leading manufacturer in the industry. Our dedication to quality and innovation ensures our products meet the demands of even the most challenging applications.

table { width: 700px; margin: 20px auto; border-collapse: collapse;}th, td { border: 1px solid #ddd; padding: 8px; text-align: left;}th { background-color: #f2f2f2;}