- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

The Comprehensive Guide to Use of Graphite Electrodes

2025-06-12

The Comprehensive Guide to Use of Graphite Electrodes

This guide explores the diverse applications of graphite electrodes, covering their properties, manufacturing processes, and various industrial uses. We’ll delve into the advantages and disadvantages of using graphite electrodes across different sectors, providing practical examples and insights for a comprehensive understanding. Learn about selecting the right electrode for your specific needs and optimizing its performance for maximum efficiency.

Understanding Graphite Electrodes

What are Graphite Electrodes?

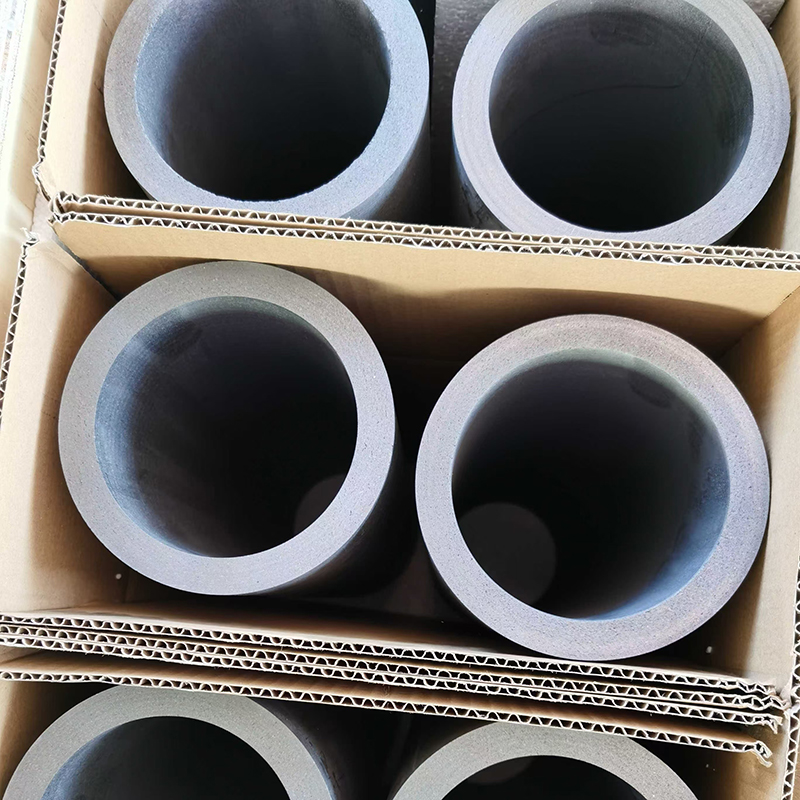

Graphite electrodes are cylindrical rods or blocks made from high-purity graphite. Their exceptional electrical conductivity, high thermal stability, and resistance to chemical corrosion make them invaluable in various industries. The manufacturing process involves careful selection of raw materials, purification, and high-temperature graphitization to achieve the desired properties. The quality and performance of a graphite electrode depend heavily on its density, purity, and crystalline structure. Key characteristics include high electrical conductivity, resistance to thermal shock, and low reactivity. The choice of graphite electrode depends heavily on the specific application, demanding careful consideration of factors such as size, shape, and grade.

Types and Grades of Graphite Electrodes

Graphite electrodes are categorized into various grades based on their properties and intended applications. These grades differ in terms of their density, strength, and resistivity. High-power applications often require electrodes with higher density and lower resistivity, while some applications prioritize strength and resistance to thermal shock. The selection of a suitable grade requires a thorough understanding of the operational parameters and the chemical environment involved. For example, the selection process will differ for use in electric arc furnaces versus electrolytic processes. More detailed information on specific grades can be found on the manufacturer’s website, such as Hebei Yaofa Carbon Co., Ltd., a leading supplier of high-quality graphite electrodes.

Applications of Graphite Electrodes

Electric Arc Furnaces (EAFs)

One of the most significant applications of graphite electrodes is in electric arc furnaces (EAFs) used for steelmaking. The high electrical conductivity of graphite electrodes allows for efficient transfer of electrical energy to generate the intense heat required to melt and refine steel. The electrodes must withstand extremely high temperatures and intense wear and tear. Proper electrode selection and maintenance are crucial for optimizing EAF productivity and efficiency.

Electrolysis Processes

Graphite electrodes play a vital role in various electrolytic processes, such as the production of aluminum, chlorine, and caustic soda. Their excellent electrical conductivity and chemical inertness make them ideal for conducting electricity and facilitating the electrochemical reactions. The selection of electrode material must be precise considering the specific chemical environment and process conditions to ensure both performance and longevity. Considerations such as electrode spacing and current density significantly impact the overall efficiency of these processes.

Other Industrial Applications

Beyond EAFs and electrolysis, graphite electrodes find applications in other industrial processes, including: continuous casting, metal refining, powder metallurgy, and the production of certain chemicals and materials. Their versatility allows for adaptations to a wide range of specific applications. The chemical inertness of high-quality graphite electrodes minimizes contamination and ensures product quality.

Factors Affecting Graphite Electrode Performance

Electrode Consumption and Degradation

The consumption rate of graphite electrodes depends on several factors, including current density, operating temperature, and the chemical environment. Understanding these factors allows for improved operational planning and reduced production costs. The physical properties of the electrode itself also play a vital role in the rate of degradation. Proper maintenance and regular inspection are critical for maximizing electrode lifespan.

Maintenance and Replacement

Regular inspection and timely replacement of worn graphite electrodes are essential for maintaining production efficiency and preventing costly downtime. A maintenance schedule must account for the specific operational parameters, environmental factors, and the grade of the graphite electrode used. Careful planning and preventative maintenance can significantly extend the lifespan of the electrodes and reduce operating costs. Manufacturer guidelines should always be followed for proper maintenance practices.

Choosing the Right Graphite Electrode

Selecting the appropriate graphite electrode requires careful consideration of the specific application and operating conditions. Factors such as the required current density, operating temperature, and the chemical environment must be taken into account. Consultation with graphite electrode manufacturers like Hebei Yaofa Carbon Co., Ltd. can assist in making an informed decision, ensuring optimal performance and efficiency.

| Factor | Considerations |

|---|---|

| Current Density | Higher current density requires electrodes with lower resistivity. |

| Operating Temperature | High temperatures require electrodes with high thermal shock resistance. |

| Chemical Environment | Electrode material must be compatible with the chemicals involved. |

| Budget | Balance performance requirements with cost-effectiveness. |

This information is for general guidance only and should not be considered exhaustive. For specific applications, consult with a graphite electrode specialist or refer to the relevant manufacturer’s specifications. Remember to always prioritize safety when handling graphite electrodes.