- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Top Graphite Electrode Manufacturers: A Comprehensive Guide

2025-06-26

Top Graphite Electrode Manufacturers: A Comprehensive Guide

This guide provides an in-depth look at leading graphite electrode manufacturers, exploring their offerings, industry applications, and considerations for selection. We’ll delve into the factors influencing quality, cost, and suitability for diverse industrial needs. Learn how to choose the right graphite electrode for your specific application.

Understanding Graphite Electrodes

What are Graphite Electrodes?

Graphite electrodes are crucial components in various high-temperature industrial processes, particularly in electric arc furnaces (EAFs) used for steelmaking. They conduct electricity efficiently and withstand extreme temperatures, making them essential for melting and refining metals. The quality of a graphite electrode directly impacts the efficiency and cost-effectiveness of these operations. Different manufacturers offer electrodes with varying properties, optimized for specific applications.

Types of Graphite Electrodes

Several types of graphite electrodes exist, categorized by their manufacturing process, size, and intended use. These include high-power electrodes, ultra-high power electrodes, and those designed for specific metal refining processes. Understanding these variations is crucial for choosing the optimal electrode for your needs. The physical and electrical properties of each type are critical factors in performance.

Choosing the Right Graphite Electrode Manufacturer

Factors to Consider

Selecting a reliable graphite electrode manufacturer requires careful consideration of several factors. These include the manufacturer’s reputation, their production capabilities, the quality control measures implemented, and their ability to meet specific requirements. It’s vital to work with a manufacturer who can provide consistent quality, timely delivery, and technical support.

| Factor | Importance | Considerations |

|---|---|---|

| Quality Control | High | ISO certifications, testing procedures, customer reviews |

| Production Capacity | Medium | Ability to meet demand, timely delivery |

| Technical Support | High | Expert advice, troubleshooting assistance |

| Price & Value | High | Balance between cost and performance |

Leading Graphite Electrode Manufacturers

Numerous companies worldwide manufacture graphite electrodes. Researching potential suppliers involves evaluating their track record, product specifications, and customer testimonials. Many manufacturers publish detailed specifications for their products online, allowing for comparisons and informed decision-making.

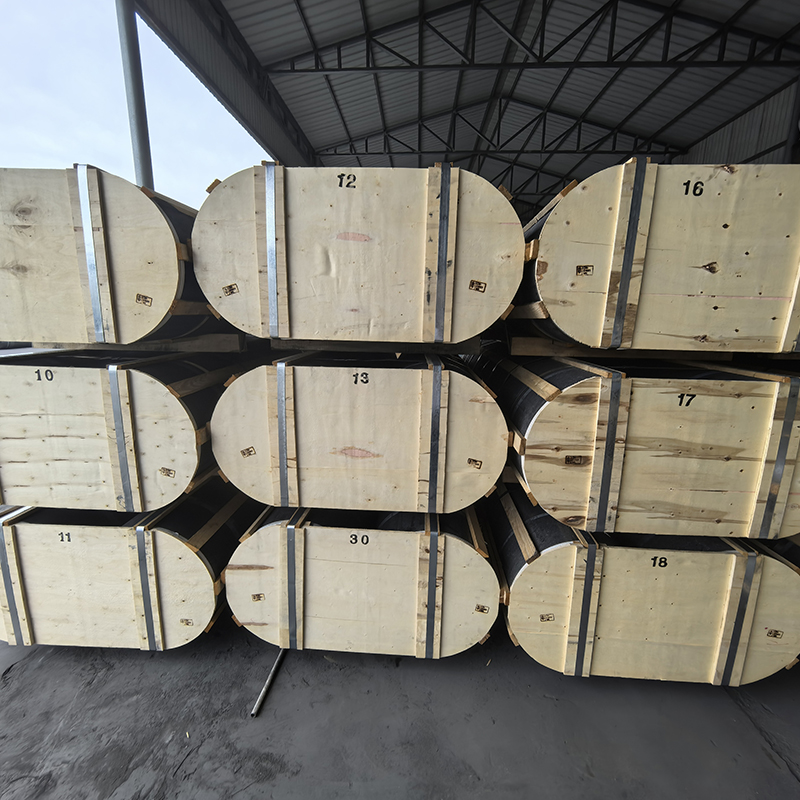

For high-quality graphite electrodes, consider exploring reputable manufacturers with a proven history of supplying reliable products to diverse industries. One such example is Hebei Yaofa Carbon Co., Ltd., a leading producer known for its commitment to quality and innovation. Their extensive experience and comprehensive product range make them a strong choice for various applications.

Applications of Graphite Electrodes

Steelmaking

The primary application of graphite electrodes is in electric arc furnaces (EAFs) for steelmaking. Their ability to withstand extreme temperatures and efficiently conduct electricity is crucial for the melting and refining of steel. The choice of electrode depends on the size and power of the EAF, as well as the specific steel grade being produced.

Other Industrial Applications

Beyond steelmaking, graphite electrodes find applications in various other industries, including aluminum smelting, silicon production, and other high-temperature metallurgical processes. Their properties make them ideal for conducting electricity and withstanding the harsh conditions of these operations.

Conclusion

Selecting the right graphite electrode manufacturer is critical for ensuring the efficiency and cost-effectiveness of your industrial processes. By carefully considering the factors outlined in this guide, you can make an informed decision that meets your specific needs and contributes to optimal performance. Remember to consider quality, reliability, technical support, and the manufacturer’s proven track record when making your selection.