- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Top Graphite Electrode Manufacturers Worldwide

2025-06-20

Top Graphite Electrode Manufacturers Worldwide

This comprehensive guide explores the leading graphite electrode manufacturers in the world, examining their capabilities, product offerings, and market presence. We delve into the key factors influencing the selection of these crucial industrial components and provide insights for businesses seeking reliable suppliers. Discover which manufacturers consistently deliver high-quality products and meet the demands of diverse industries.

Understanding the Graphite Electrode Market

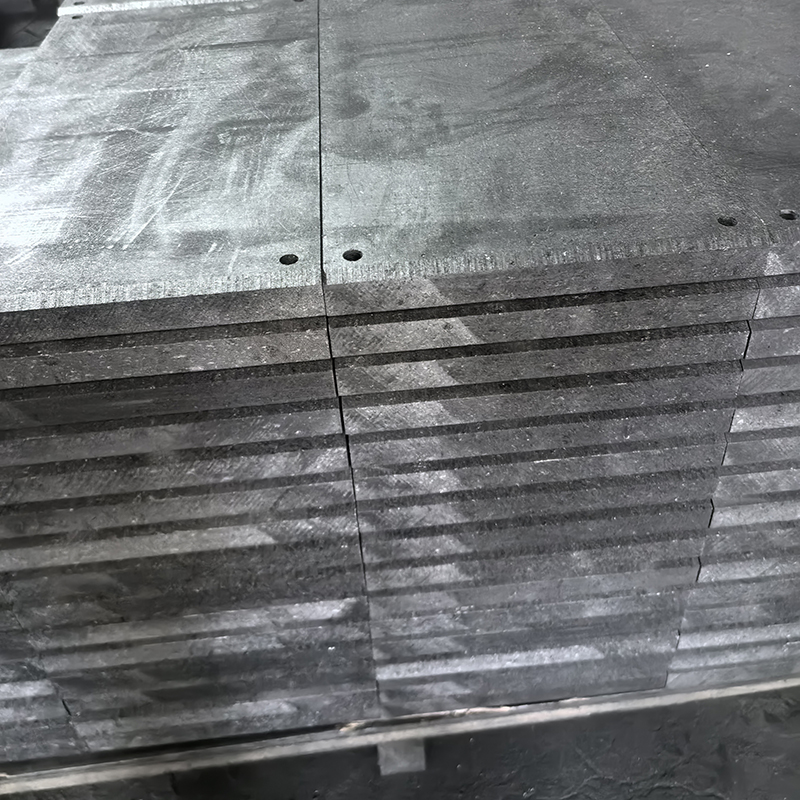

Graphite electrodes are essential components in various industries, primarily in electric arc furnaces (EAFs) for steelmaking. Their quality significantly impacts the efficiency and cost-effectiveness of steel production. The global market for graphite electrodes is dynamic, driven by factors such as steel production growth, technological advancements in electrode manufacturing, and raw material availability. Choosing the right manufacturer is crucial for securing consistent supply and optimal performance.

Key Factors in Selecting a Graphite Electrode Manufacturer

Quality and Consistency

The consistency of the graphite electrode‘s physical and chemical properties is paramount. Manufacturers should adhere to strict quality control measures throughout the production process, ensuring uniformity in density, resistivity, and other crucial characteristics. Independent certifications and testing reports are vital for verifying the quality claims.

Production Capacity and Delivery Reliability

Reliable supply is essential for uninterrupted operations. Consider the manufacturer’s production capacity and their ability to meet your anticipated demand consistently. A proven track record of on-time delivery is a significant indicator of a reliable partner. Inquire about their logistics network and capabilities.

Technological Innovation

The industry is constantly evolving, with ongoing research and development into improving graphite electrode performance and efficiency. Leading manufacturers invest in R&D to develop innovative products and processes, often resulting in improved energy efficiency, longer service life, and reduced operational costs.

Global Reach and Support

For businesses operating across multiple regions, a manufacturer with a global presence and comprehensive support network is essential. This ensures easy access to technical assistance, spare parts, and timely responses to any issues that may arise.

Leading Graphite Electrode Manufacturers

While a definitive ranking is difficult due to constantly shifting market dynamics and proprietary data, several manufacturers consistently stand out for their quality, reputation, and global reach. These manufacturers are often distinguished by their vertical integration (control over raw materials), advanced manufacturing processes, and dedication to research and development. Researching each manufacturer individually is crucial to understand their specific capabilities and suitability for your needs. One such manufacturer with a strong reputation is Hebei Yaofa Carbon Co., Ltd., known for its high-quality products and commitment to customer satisfaction.

Choosing the Right Partner for Your Needs

Selecting the best graphite electrode manufacturer requires careful consideration of several factors. Understanding your specific requirements, such as electrode size, grade, and quantity, is the first step. Thorough due diligence, including reviewing manufacturer certifications, conducting site visits, and obtaining references, will further help in making an informed decision. Consider long-term partnerships for sustained value and reliability.

Conclusion

The selection of a graphite electrode manufacturer is a crucial decision for businesses relying on these components. By understanding the key factors discussed above and conducting thorough research, you can identify a reliable partner that meets your requirements and contributes to the success of your operations. Remember to prioritize quality, consistency, and a proven track record when making your choice.