- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Selecting the Right Normal Power Graphite Electrode

2025-07-04

Understanding and Selecting the Right Normal Power Graphite Electrode

This comprehensive guide explores the intricacies of normal power graphite electrodes, providing insights into their composition, applications, selection criteria, and crucial factors to consider for optimal performance. We’ll delve into the technical aspects, addressing common questions and offering practical advice for users seeking to maximize efficiency and longevity in their operations.

What are Normal Power Graphite Electrodes?

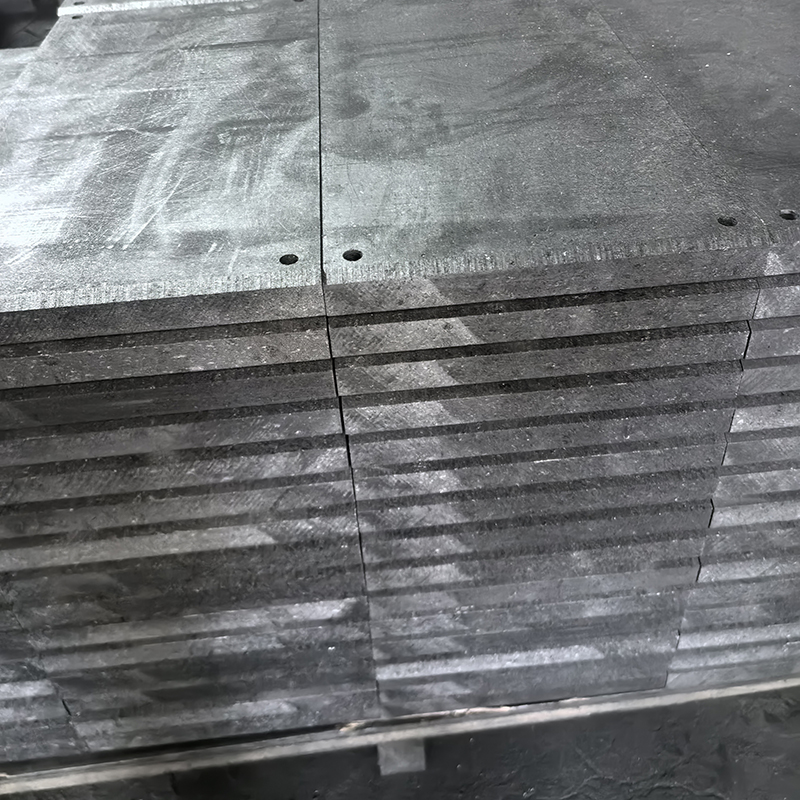

Normal power graphite electrodes are a crucial component in various industrial processes, primarily electric arc furnaces (EAFs) used in steelmaking. These electrodes, made from high-quality graphite, conduct electricity to generate the intense heat necessary for melting and refining the steel. Their performance directly impacts the efficiency and cost-effectiveness of the entire operation. The term normal power refers to their typical power consumption levels compared to other specialized electrodes designed for higher power applications. Understanding the characteristics and specifications is crucial for selecting the appropriate electrode for specific needs.

Key Properties and Specifications of Normal Power Graphite Electrodes

Several critical properties dictate the performance of a normal power graphite electrode. These include:

Electrical Resistivity

Lower electrical resistivity is desirable, leading to reduced energy consumption during operation. This property significantly impacts the overall efficiency of the EAF process. Manufacturers provide detailed specifications for this crucial parameter.

Mechanical Strength

The electrode must withstand the substantial thermal and mechanical stresses experienced within the EAF. High mechanical strength ensures durability and minimizes breakage, leading to reduced downtime and increased productivity.

Thermal Shock Resistance

Rapid temperature fluctuations are common in EAFs. High thermal shock resistance prevents cracking and extends the operational lifespan of the electrode. This characteristic is vital for maintaining consistent performance.

Density and Porosity

The density and porosity of the graphite influence its electrical conductivity and mechanical strength. Optimizing these properties is essential for achieving optimal performance. Manufacturers typically provide detailed data on these aspects.

Selecting the Right Normal Power Graphite Electrode: Factors to Consider

Choosing the appropriate normal power graphite electrode depends on several factors. These include:

- EAF size and capacity: Larger furnaces often require electrodes with higher current carrying capacity.

- Steelmaking process: Different steel grades and production methods may necessitate electrodes with specific properties.

- Operating conditions: Factors like temperature, voltage, and current need to be considered for optimal electrode performance.

- Budget and cost-effectiveness: Balancing the initial investment with long-term operating costs is crucial.

Comparison of Normal Power Graphite Electrodes from Different Manufacturers

To illustrate the variations in specifications, let’s consider a simplified comparison (Note: Actual specifications vary greatly between manufacturers and electrode types. Consult individual manufacturer datasheets for accurate information).

| Manufacturer | Electrical Resistivity (μΩ·cm) | Mechanical Strength (MPa) | Thermal Shock Resistance |

|---|---|---|---|

| Manufacturer A | 7.5 | 30 | Excellent |

| Manufacturer B | 8.0 | 28 | Good |

| Hebei Yaofa Carbon Co., Ltd. https://www.yaofatansu.com/ | 7.2 | 32 | Superior |

Conclusion

Selecting the optimal normal power graphite electrode requires a thorough understanding of its properties and the specific operational requirements. By carefully considering the factors discussed above, users can ensure efficient and cost-effective steel production. Always consult with experienced professionals and refer to the manufacturer’s specifications to make an informed decision. For high-quality normal power graphite electrodes, consider exploring the offerings from reputable manufacturers like Hebei Yaofa Carbon Co., Ltd. https://www.yaofatansu.com/.