- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Selecting UCAR Graphite Electrodes

2025-04-27

Understanding and Selecting UCAR Graphite Electrodes

This comprehensive guide explores the world of UCAR graphite electrodes, covering their properties, applications, selection criteria, and key considerations for various industries. Learn how to choose the right electrode for optimal performance and efficiency in your processes. We delve into the specifics of different types and grades, providing insights to help you make informed decisions.

What are UCAR Graphite Electrodes?

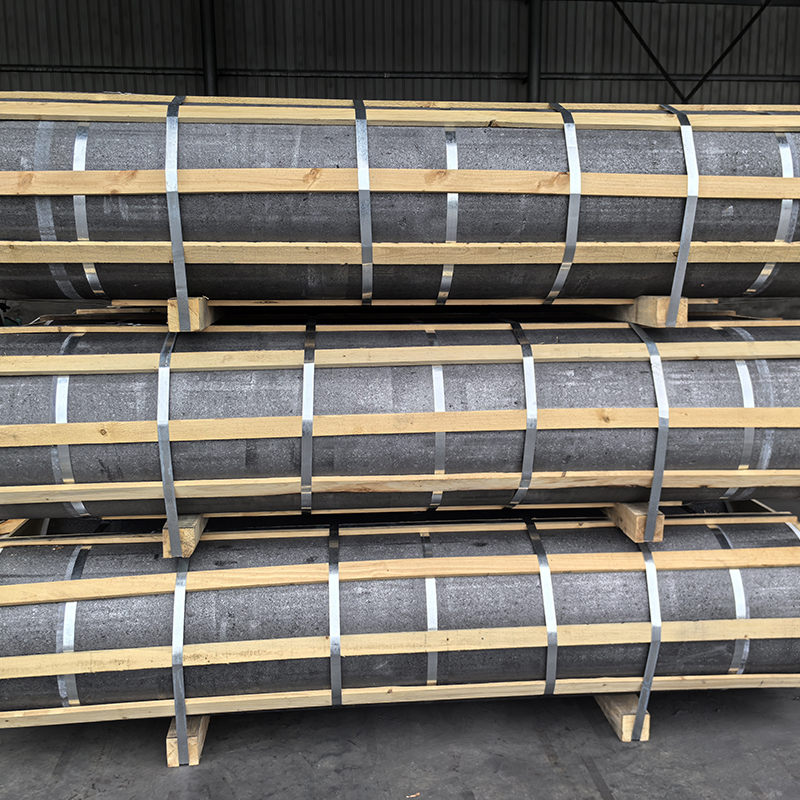

UCAR graphite electrodes, manufactured by various companies (including those with a history tied to Union Carbide’s legacy), are high-quality graphite components crucial in diverse industrial applications. They are prized for their exceptional electrical conductivity, high-temperature resistance, and chemical inertness. These properties make them ideal for use in electric arc furnaces (EAFs), aluminum smelting, and other high-temperature processes. The specific characteristics of a UCAR graphite electrode depend heavily on its grade and intended application.

Types and Grades of UCAR Graphite Electrodes

The market offers a wide variety of UCAR graphite electrodes, categorized by their grade and physical properties. These grades are engineered to meet specific performance requirements. Factors influencing grade selection include:

Factors Affecting Electrode Grade Selection

- Required Electrical Conductivity

- Thermal Shock Resistance

- Oxidation Resistance

- Mechanical Strength

- Specific Application (e.g., EAF steelmaking, aluminum production)

Higher-grade electrodes generally exhibit superior performance characteristics but come at a higher cost. Choosing the appropriate grade involves careful consideration of the trade-off between performance and cost.

Applications of UCAR Graphite Electrodes

Electric Arc Furnaces (EAFs)

In EAF steelmaking, UCAR graphite electrodes are essential for transferring electrical energy to melt scrap metal and produce steel. Their ability to withstand extreme temperatures and electrical currents is critical for efficient and reliable furnace operation. The selection of the appropriate electrode size and grade is crucial for optimizing energy consumption and minimizing electrode consumption.

Aluminum Smelting

The aluminum industry relies on UCAR graphite electrodes for the Hall-Héroult process, where alumina is reduced to aluminum. The electrodes must withstand extremely harsh conditions, including high temperatures and corrosive molten electrolyte. Specific electrode grades are optimized for this demanding application.

Other Industrial Applications

Beyond EAFs and aluminum smelting, UCAR graphite electrodes find use in various other high-temperature processes, including the production of silicon, ferroalloys, and other specialty metals. Their unique properties make them versatile tools in many industrial settings.

Selecting the Right UCAR Graphite Electrode

The selection of the best UCAR graphite electrode requires careful consideration of several factors:

| Factor | Considerations |

|---|---|

| Application | Specific requirements vary widely depending on the application (EAF, aluminum smelting, etc.). |

| Current Requirements | Electrode diameter and grade should match the current demands of the process. |

| Budget | Higher-grade electrodes often provide better performance but at a higher cost. |

| Supplier | Choose a reputable supplier who can provide quality products and technical support. Consider exploring options like Hebei Yaofa Carbon Co., Ltd. for your UCAR graphite electrodes needs. |

Conclusion

Understanding the properties and applications of UCAR graphite electrodes is crucial for optimizing various industrial processes. Careful consideration of factors such as grade, application requirements, and cost-effectiveness is essential for selecting the right electrode to ensure optimal performance, efficiency, and longevity. Always consult with reputable suppliers for expert guidance and support in making the best choice for your specific needs.