- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Utilizing Carbon Graphite Felt

2025-05-07

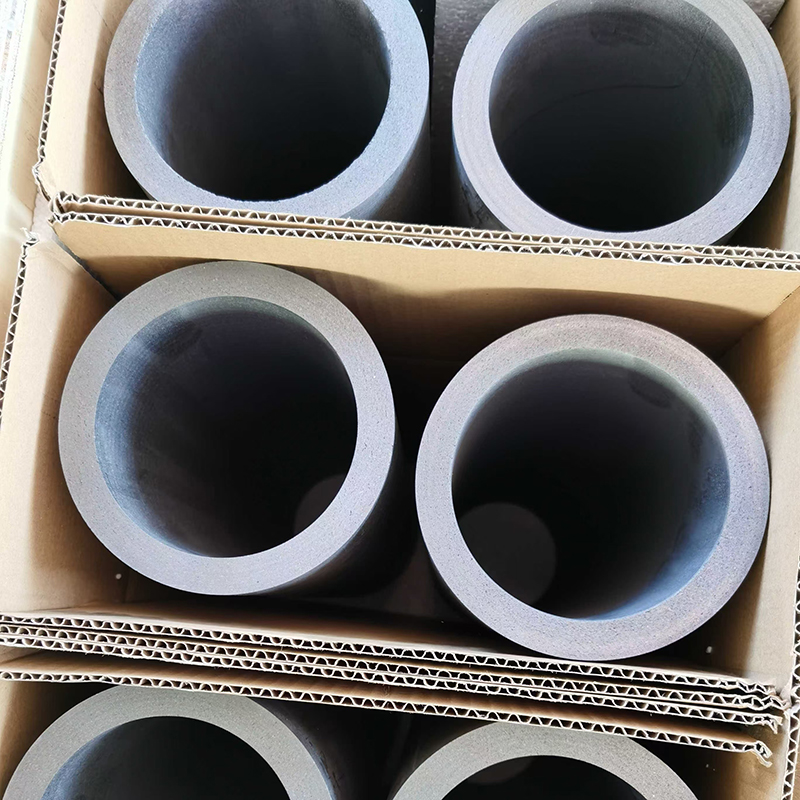

Understanding and Utilizing Carbon Graphite Felt

This comprehensive guide explores the properties, applications, and manufacturing processes of carbon graphite felt. We delve into its unique characteristics, making it a versatile material across various industries. Learn about its advantages, disadvantages, and how to select the right type for your specific needs. We will also examine key factors impacting its performance and explore future trends in carbon graphite felt technology.

What is Carbon Graphite Felt?

Carbon graphite felt is a porous material made from carbon fibers bonded together. Unlike traditional graphite, it possesses a unique combination of properties that make it suitable for a wide range of applications. Its porous nature allows for excellent permeability, while its carbon composition provides high thermal conductivity and chemical resistance. The manufacturing process involves carefully controlling fiber alignment and bonding techniques to achieve the desired properties, including density, porosity, and thermal conductivity.

Properties of Carbon Graphite Felt

Thermal Conductivity

One of the key advantages of carbon graphite felt is its high thermal conductivity. This property makes it ideal for applications requiring efficient heat transfer, such as heat exchangers and thermal insulation. The thermal conductivity can vary depending on the manufacturing process and the type of carbon fibers used. Higher density felts generally exhibit higher thermal conductivity.

Chemical Resistance

Carbon graphite felt demonstrates excellent resistance to various chemicals and corrosive environments. This makes it suitable for use in harsh chemical processing applications. However, its resistance may vary depending on the specific chemical and its concentration. Always consult the manufacturer’s specifications for compatibility with specific chemicals. Hebei Yaofa Carbon Co., Ltd. offers detailed information on the chemical resistance of their products.

Porosity and Permeability

The porous nature of carbon graphite felt contributes to its excellent permeability to gases and liquids. This characteristic is crucial in applications requiring filtration, diffusion, or wicking. The porosity and permeability are controlled during manufacturing and influence the overall performance of the material.

Applications of Carbon Graphite Felt

High-Temperature Applications

Due to its high-temperature resistance, carbon graphite felt finds extensive use in high-temperature applications, such as furnace linings, thermal insulation in aerospace components, and crucibles for metal processing. Its ability to withstand extreme temperatures without significant degradation makes it a valuable material in these demanding environments.

Filtration and Separation

The porous structure of carbon graphite felt makes it an effective filtration medium. It can be used to filter gases and liquids, removing impurities and contaminants. The pore size can be controlled during the manufacturing process to achieve the desired filtration efficiency. This application is prevalent in various industries, including chemical processing and environmental remediation.

Electrochemical Applications

Carbon graphite felt‘s electrical conductivity and chemical resistance make it a suitable material for electrochemical applications such as battery electrodes, fuel cells, and electrolyzers. Its large surface area facilitates efficient electrochemical reactions.

Choosing the Right Carbon Graphite Felt

Selecting the appropriate carbon graphite felt requires considering several factors, including density, porosity, thermal conductivity, chemical resistance, and intended application. Consult with manufacturers like Hebei Yaofa Carbon Co., Ltd. to determine the best option for your specific needs. They can provide tailored solutions based on your application requirements.

Comparison of Different Types of Carbon Graphite Felt

| Property | Type A | Type B |

|---|---|---|

| Density (g/cm3) | 1.5 | 1.8 |

| Porosity (%) | 70 | 65 |

| Thermal Conductivity (W/m·K) | 150 | 180 |

Note: These values are illustrative examples and may vary depending on the specific manufacturer and production process.

Future Trends in Carbon Graphite Felt

Ongoing research and development are focused on improving the properties of carbon graphite felt, including enhancing its thermal conductivity, increasing its chemical resistance, and developing new manufacturing techniques to create more customized materials. Further exploration into sustainable and cost-effective manufacturing processes is also a key area of focus.

This information is for general guidance only. Always refer to the manufacturer’s data sheet for precise specifications and safety information before using carbon graphite felt in any application.