- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Utilizing EDM Graphite

2025-04-27

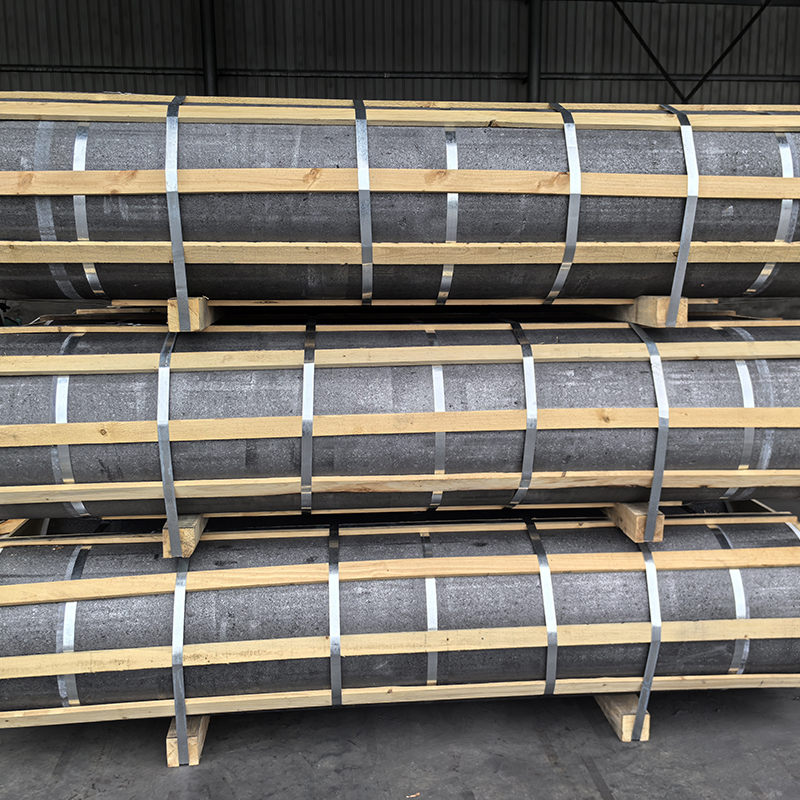

Understanding and Utilizing EDM Graphite

This comprehensive guide explores the properties, applications, and sourcing of EDM graphite, a crucial material in electrical discharge machining (EDM). We’ll delve into its characteristics, compare different grades, and discuss considerations for selecting the right EDM graphite for your specific needs. Learn how to optimize your EDM processes and achieve superior results by understanding the nuances of this specialized material.

What is EDM Graphite?

EDM graphite, also known as electrode graphite, is a high-purity form of graphite specifically engineered for use in electrical discharge machining. This process removes material from a workpiece by using a series of precisely controlled electrical discharges. The EDM graphite electrode acts as a tool, shaping the workpiece with remarkable accuracy. Its properties, like high electrical conductivity, thermal stability, and machinability, make it ideally suited for this demanding application. The quality and type of EDM graphite significantly impact the efficiency and precision of the EDM process.

Key Properties of EDM Graphite

Electrical Conductivity

High electrical conductivity is paramount for efficient EDM. EDM graphite possesses excellent conductivity, ensuring consistent and reliable sparking during the machining process. This translates to faster material removal rates and improved surface finish.

Thermal Stability

The intense heat generated during EDM requires the electrode material to withstand high temperatures without significant degradation. EDM graphite exhibits exceptional thermal stability, maintaining its structural integrity even under extreme conditions. This prevents premature electrode wear and ensures consistent machining performance.

Machinability

EDM graphite needs to be easily machinable to create electrodes of intricate shapes and sizes. It’s readily shaped using conventional machining techniques, allowing for the creation of customized electrodes for various applications.

Different Grades of EDM Graphite

EDM graphite comes in various grades, each with slightly different properties optimized for specific applications. The choice of grade depends on factors such as the material being machined, the desired surface finish, and the required machining speed. Some common grades include high-density graphite, isotropic graphite, and fine-grained graphite. The selection process requires careful consideration of the desired outcome.

Selecting the Right EDM Graphite

Choosing the appropriate EDM graphite is critical for successful EDM processes. Factors to consider include the material being machined, desired surface finish, and required machining speed. Consult with experienced EDM specialists or refer to manufacturer specifications for guidance. Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) offers a range of high-quality EDM graphite products tailored to various applications.

Applications of EDM Graphite

EDM graphite finds widespread use in various industries, including aerospace, automotive, and medical. Its precision and ability to machine complex shapes make it indispensable in the creation of intricate components. Examples include molds for plastic injection molding, dies for stamping, and precision parts for aerospace applications.

EDM Graphite vs. Other Electrode Materials

| Property | EDM Graphite | Other Materials (e.g., Copper) |

|---|---|---|

| Cost | Generally lower | Can be higher |

| Machinability | High | Varies |

| Thermal Conductivity | Moderate | High |

Note: This comparison is generalized. The optimal electrode material depends on specific application requirements.

Conclusion

Understanding the properties and applications of EDM graphite is essential for anyone involved in electrical discharge machining. By carefully selecting the right grade and considering the specific machining requirements, users can optimize their processes and achieve superior results. Remember to consult with experienced professionals or manufacturers like Hebei Yaofa Carbon Co., Ltd. for expert guidance.