Understanding and Utilizing Graphite Electrode Particles

2025-07-11

Understanding and Utilizing Graphite Electrode Particles

This comprehensive guide explores the properties, applications, and market considerations surrounding graphite electrode particles. We delve into the various types, their manufacturing processes, and their crucial role in diverse industries. Learn how to select the right graphite electrode particles for your specific needs, considering factors like purity, size, and morphology. Discover leading suppliers and explore future trends in this vital material sector.

Types and Properties of Graphite Electrode Particles

Different Grades and Specifications

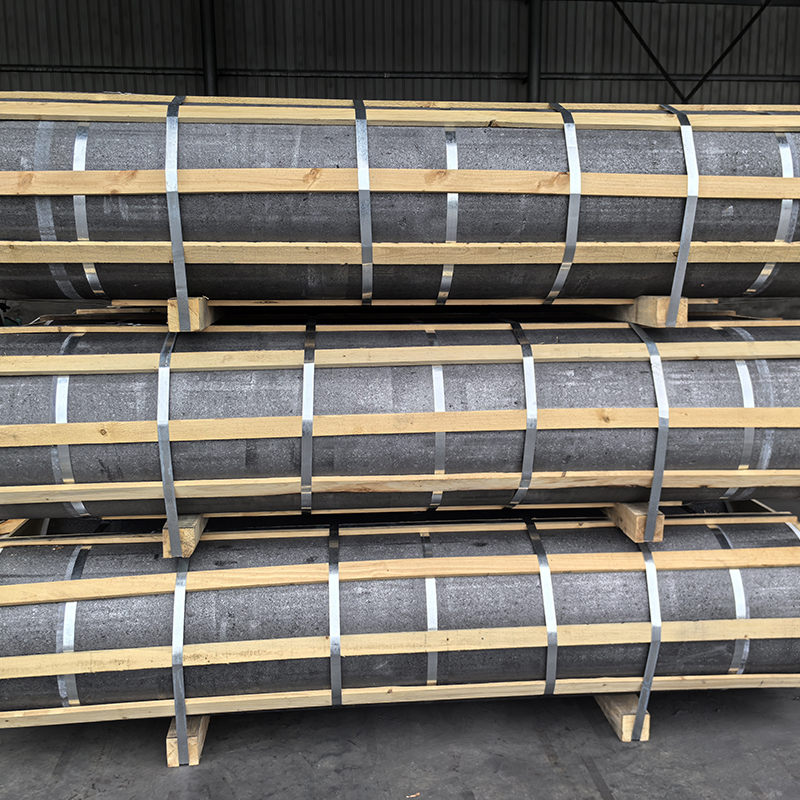

Graphite electrode particles are available in various grades, each tailored to specific applications. These grades are determined by factors such as purity, particle size distribution, and surface area. High-purity graphite electrode particles are often preferred for demanding applications requiring minimal contamination. Particle size is critical; finer particles may be suitable for dispersion in liquids, while coarser particles are better suited for applications requiring higher strength or abrasion resistance. Understanding these specifications is key to selecting the right product for your needs. For detailed specifications and available grades, refer to reputable suppliers such as Hebei Yaofa Carbon Co., Ltd., a leading manufacturer in the field. They offer a range of high-quality graphite electrode particles designed for various industrial applications.

Manufacturing Processes and Purity

The manufacturing process significantly influences the properties of graphite electrode particles. Common methods include crushing and grinding of larger graphite electrodes, followed by sieving and purification processes to achieve the desired particle size and purity level. The purity level is crucial and directly impacts the performance of the particles in various applications. Impurities can hinder electrical conductivity, chemical reactivity, and overall performance. Higher purity grades typically come at a premium but often justify the cost with improved results.

Applications of Graphite Electrode Particles

Steelmaking and Foundry Applications

A significant portion of graphite electrode particles are used in steelmaking and foundry applications. They serve as a crucial component in electric arc furnaces (EAFs), contributing to efficient energy transfer and improved steel quality. Their properties allow them to withstand high temperatures and aggressive chemical environments during the steelmaking process. The specific grade of graphite electrode particles selected often depends on the type of steel being produced and the desired properties of the final product. The consistent supply of high-quality graphite electrode particles is essential for efficient and reliable steel production.

Other Industrial Applications

Beyond steelmaking, graphite electrode particles find applications in diverse industries, including:

- Battery Manufacturing: Used as conductive additives in lithium-ion batteries, improving conductivity and performance.

- Refractory Materials: Incorporated into refractory materials to enhance their thermal shock resistance and conductivity.

- Lubricants: Their low friction coefficient makes them suitable for use as solid lubricants in high-temperature applications.

- Conductive Composites: Used to improve the electrical conductivity of various composite materials.

Choosing the Right Graphite Electrode Particles

Selecting the appropriate graphite electrode particles requires careful consideration of several factors:

- Particle Size: Influences flowability, packing density, and surface area.

- Purity: Determines the performance characteristics and suitability for specific applications.

- Morphology: Affects the material’s properties and behavior.

- Application Requirements: The specific needs of the application will dictate the appropriate grade and properties.

Future Trends and Market Outlook

The demand for graphite electrode particles is expected to increase in the coming years, driven by growth in various industries, including renewable energy and electric vehicles. Research and development are continuously focused on improving the quality and performance of these particles, including advancements in production techniques and exploring new applications. The market is witnessing an increasing emphasis on sustainability and environmentally friendly production methods.

| Property | Typical Value (Example) |

|---|---|

| Particle Size | 50-150 μm |

| Purity | 99.5% |

| Bulk Density | 1.8 g/cm3 |

Note: The values in the table are examples and may vary depending on the specific product and supplier. Consult with Hebei Yaofa Carbon Co., Ltd. for detailed specifications.