- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Utilizing UHP Ultra High Power Graphite Electrodes

2025-06-16

Understanding and Utilizing UHP Ultra High Power Graphite Electrodes

This article provides a comprehensive overview of UHP ultra high power graphite electrodes, exploring their properties, applications, and the factors influencing their performance. We delve into the manufacturing process, key considerations for selection, and best practices for optimal utilization. Learn how to maximize efficiency and lifespan, ultimately contributing to improved productivity and cost savings in your operations.

What are UHP Ultra High Power Graphite Electrodes?

UHP ultra high power graphite electrodes represent the pinnacle of graphite electrode technology. They are characterized by their exceptionally high purity, fine grain size, and superior electrical conductivity. These characteristics contribute to their significantly increased power capacity compared to standard graphite electrodes, leading to improved efficiency in various industrial processes.

Manufacturing Process and Key Properties

The Manufacturing Process

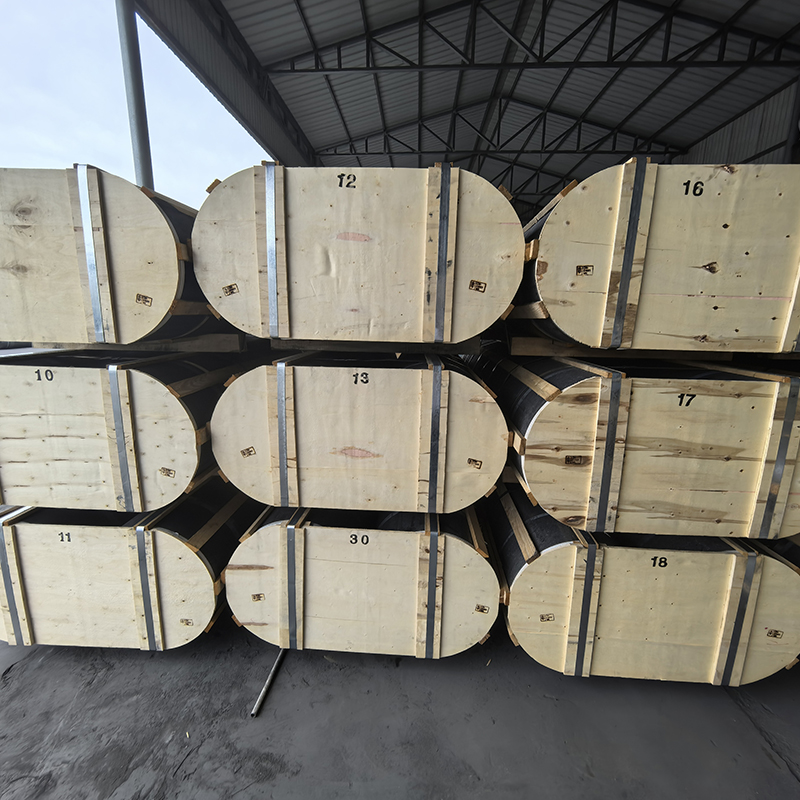

The production of UHP ultra high power graphite electrodes involves a complex process, starting with the selection of high-quality raw materials. These materials undergo meticulous purification and are then carefully processed to achieve the desired fine grain structure. High-temperature graphitization further enhances the material’s properties. This precise manufacturing process ensures the exceptional quality and performance of these electrodes. Specific details regarding the process vary among manufacturers, with companies like Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) being a prominent example.

Key Properties and Their Significance

Several key properties distinguish UHP ultra high power graphite electrodes:

- High Purity: Minimizes impurities that can negatively impact electrical conductivity and lifespan.

- Fine Grain Size: Enhances strength, thermal shock resistance, and overall performance.

- Exceptional Electrical Conductivity: Enables the efficient transfer of electrical power, reducing energy consumption.

- High Thermal Conductivity: Facilitates heat dissipation, contributing to extended electrode lifespan.

- High Oxidation Resistance: Improves resistance to wear and tear, prolonging operational life.

These superior properties translate to cost savings and increased productivity in applications where they are used.

Applications of UHP Ultra High Power Graphite Electrodes

UHP ultra high power graphite electrodes find extensive use in a wide range of industries. Their superior performance makes them particularly well-suited for demanding applications such as:

- Electric Arc Furnaces (EAFs): In steelmaking, these electrodes deliver greater efficiency and reduced energy consumption compared to conventional electrodes.

- Aluminum Smelting: Their high power capacity enables the efficient production of aluminum, optimizing the smelting process.

- Other High-Temperature Applications: Their robust nature and high resistance to thermal shock make them suitable for various high-temperature industrial processes.

Selection Criteria and Optimization

Factors to Consider When Selecting UHP Ultra High Power Graphite Electrodes

The selection of the appropriate UHP ultra high power graphite electrodes depends on several factors, including:

- Specific Application Requirements: The demands of the application will dictate the necessary properties of the electrodes.

- Power Requirements: The desired power capacity of the electrodes should align with the application’s needs.

- Budgetary Constraints: While high-quality electrodes offer long-term cost savings, budgetary considerations are important.

- Manufacturer Reputation: Choosing a reputable manufacturer like Hebei Yaofa Carbon Co., Ltd. ensures reliable quality and performance.

Optimizing Performance and Lifespan

To maximize the performance and lifespan of UHP ultra high power graphite electrodes, it’s crucial to follow best practices, including proper handling, storage, and operational procedures. Regular inspection and maintenance also play a significant role in ensuring optimal utilization.

Comparison of UHP Graphite Electrodes with Other Types

| Feature | UHP Graphite Electrodes | Standard Graphite Electrodes |

|---|---|---|

| Power Capacity | Significantly Higher | Lower |

| Purity | Very High | Lower |

| Lifespan | Longer | Shorter |

| Cost | Higher Initial Cost | Lower Initial Cost |

While UHP ultra high power graphite electrodes have a higher initial cost, their superior performance and longer lifespan often result in significant long-term cost savings.

Note: Data comparisons are based on general industry knowledge and may vary depending on specific manufacturers and product specifications.