- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding Graphite Electrode Use

2025-05-25

Understanding Graphite Electrode Use

This comprehensive guide explores the diverse applications of graphite electrodes, delving into their properties, manufacturing processes, and various industrial uses. We’ll cover everything from the fundamental principles to advanced applications, providing you with a thorough understanding of this crucial material.

What are Graphite Electrodes?

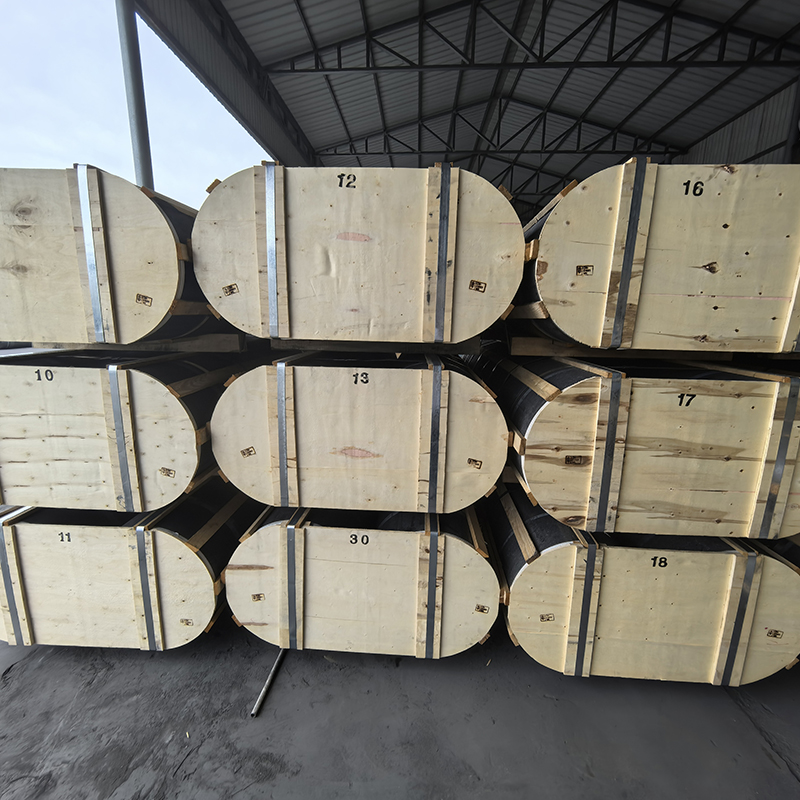

Graphite electrodes are essential components in numerous high-temperature industrial processes. Made from high-purity graphite, these electrodes are known for their exceptional electrical conductivity, high thermal shock resistance, and chemical inertness. Their unique properties make them ideal for applications demanding extreme conditions. The manufacturing process involves careful selection of raw materials and sophisticated techniques to ensure consistent quality and performance. Understanding the different grades and types of graphite electrodes is crucial for selecting the right one for a specific application. For example, the choice between high-power electrodes and standard electrodes depends heavily on the specific needs of the application and the desired performance characteristics.

Types and Grades of Graphite Electrodes

The market offers a wide range of graphite electrodes, categorized by size, grade, and intended application. The grade classification often reflects the purity and the resulting properties, affecting factors such as electrical conductivity and resistance to oxidation. Choosing the appropriate grade is crucial for optimizing performance and longevity. High-purity grades are often preferred for applications requiring minimal contamination, while others are better suited for less demanding applications. Many manufacturers, like Hebei Yaofa Carbon Co., Ltd., provide detailed specifications for their various electrode types, allowing for careful selection based on specific project requirements.

Key Applications of Graphite Electrodes

Electric Arc Furnaces (EAFs)

One of the most significant uses of graphite electrodes is in electric arc furnaces (EAFs) used in steelmaking. The electrodes conduct high electrical currents to generate intense heat, melting scrap metal and other raw materials. The electrode’s properties—high conductivity, thermal resistance, and low reactivity—are critical for this demanding process. The efficiency of the EAF is directly related to the quality of the graphite electrodes used, impacting energy consumption and overall steel production.

Aluminum Smelting

In the aluminum industry, graphite electrodes are vital for the electrolytic process used to extract aluminum from alumina. These electrodes act as anodes in the process, facilitating the electrochemical reactions that produce molten aluminum. The quality and performance of the graphite electrodes directly affect the energy efficiency and the overall output of the aluminum smelter. High-quality electrodes minimize electrode consumption and enhance the efficiency of the entire process.

Other Industrial Applications

Beyond steelmaking and aluminum production, graphite electrodes find applications in various other industries: In the chemical industry for electrochemical processes, in the semiconductor industry for specialized manufacturing, and in lighting technologies for high-intensity arc lamps. The versatility and durability of graphite electrodes make them suitable for a diverse range of industrial processes.

Factors Affecting Graphite Electrode Selection

Several factors need consideration when choosing graphite electrodes. These include:

| Factor | Considerations |

|---|---|

| Size and Diameter | Determined by the specific application and furnace capacity. |

| Grade and Purity | Impacts electrical conductivity, oxidation resistance, and overall lifespan. |

| Manufacturing Process | Impacts the overall quality and consistency of the electrodes. |

| Cost | Needs to be balanced against performance and lifespan. |

Conclusion

Graphite electrodes are indispensable components in various high-temperature industrial processes. Understanding their properties, applications, and selection criteria is crucial for maximizing efficiency and minimizing operational costs. The choice of graphite electrode significantly impacts the overall performance and productivity of diverse industrial applications.

Note: Information regarding specific electrode grades and specifications should be obtained from the manufacturer’s documentation. This information is for general guidance only.