- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

Columnar Carburizer

-

Yepamusoro-mhando graphite poda inowanikwa mu stock, iine huwandu hwakazara hwezvakatemerwa uye customizable sarudzo.

-

Spherical carburizer

-

Calcined petroleum coke kabhoni yekuwedzera: yakakwira kunyura mwero, inogadziriswa particle size, yakanakira kukanda uye simbi.

-

600mm ekupedzisira-yepamusoro simba graphite maelectrode ane hupamhi hwepamusoro uye kushomeka kushomeka: kuseta bhenji nyowani yekunyungudutsa zvakanaka.

-

960 Graphite Electrodes – High Power, Ultra-High Power – Worldwide Shipping

-

Rp yakajairika simba graphite electrode

-

450mm ultra-high / high-power graphite electrodes, high density uye yakaderera kuramba, inopiwa zvakananga kubva kumugadziri.

-

Metallurgical steelmaking ultra-high power graphite electrodes, high tembiricha inopikisa uye inopikisa simba, yakananga kugovera kubva kumugadziri.

-

UHP Ultra High Simba Graphiti Electrode

-

High-simba graphite electrodes: sarudzo inosarudzika yekuchengetedza simba, kuderedzwa kushandiswa, uye kunatsiridza kugadzirwa kwesimbi.

-

Graphite crucibles yakanyatsogadzirirwa zvinhu zvisina kunaka zve electrode: kupikisa kwekushisa kwepamusoro uye kupikisa oxidation; yakanakira lithium-ion bhatiri kugadzirwa

-

Mutengesi wemagraphite electrodes ane global distribution network.

-

High-temperature resistant graphite plates: conductive, thermally conductive, uye corrosion-resistant; tsika yekugadzirisa inowanikwa kune maindasitiri evira

-

Nine-gomba crucible yakanyatsogadzirirwa kune negative electrode zvinhu; inoratidzira yakaderera tsvina yemukati, yakakwirira tembiricha kuramba, uye kuenderana negraphitization maitiro

-

High-quality graphite electrodes, 600mm saizi, kutumirwa kwepasirese kunowanikwa

HP High Simba Graphite Electrode

HP High Simba Graphite Electrode Electrode pfupi Tsananguro: HP Graphite Electrode application: 1600 ~ Simbi): 1.65-1.6 (BSN)

Tsanangudzo

Marker

HP High Simba Graphite Electrode

Tsananguro pfupi:

Nyora: HP Graphite Electrode

Chikumbiro: simbi / metallurgical simbi

Kureba: 1600 ~ 2800mm

Giredhi: Hp (simba rakakwirira)

Kudzivisa (μω.m): 5.8-6.6

Kuonekera density (G / CM³): 1.65-1.70

Kuwedzera kwekuwedzera: 100-600 3TPI / 4TPI / 4TPIL

Zvishandiso Zvakabikwa: sindano coke, petroleum coke, marasha tar pitch

Mukana: Low Compration Rate

Ruvara: dema grey

DIAMETER: 250mm, 300mm, 400mm, 400mm, 450mm, 450mm, 500mm, 600mm, 650mm, 650mm, 700mm, 800mm, 800mm, 800mm

•Maitiro ekuita

•Kubata kwakanyanya: Runoramba kupokana, pakati pe5 5.8-6.μTEMBEMAM, dzinogona kuderedza kurasikirwa kweVESE, kugadzirisa Arc kugadzikana uye kubvumira density pakati pa 18-25a / cmè.

•Yakanaka yekupisa kupisa: Yakagadzirwa neyemhando yepamusoro-mhando zvigadzirwa zvakadai sepeturu coke uye sindano coke, mushure mekurapa kwakakwirira, kunogona kuchengeta zvivakwa zvepanyama uye zvemakemikari mune yakanyanya tembiricha uye isiri nyore kushatisa kana kukuvara.

•Yakakwirira Mechan Simba: Iine simba rakakura uye kukanganisa simba, ≥11.0mpa, kunogona kukanganisa kushushikana kukuru uye kukanganisa, hazvisi nyore kuputsa panguva yekushandisa, uye nechokwadi chekusimbisa uye hupenyu hwebasa hwemagetsi.

•Yakanaka Thermal kuvhundutsa kuramba: Mukutonga kwekuwedzera kudziya uye kutonhora kutenderera, zvinogona kuramba kuita kwekunetseka kwekunetseka, hazvisi nyore kupaza, kana kusimuka, nezvimwe, uye kunovandudza kusimba kweiyo electrode.

•Low ASH Zvinyorwa: ASH Zvinyorwa ≤0.2%, kusachena kushoma, kunogona kuderedza kusvibiswa kwekunyungudika

•Maitiro ekugadzira

•Raw zvinyorwa zvinosarudzwa: Petroleum Coke uye Sindano Coke ndiyo huru yekuunganidza, uye kora tar ndeye binder. Pakati pavo, sindano coke maakaunti kweanenge makumi matatu muzana, uye simba rayo rakakwirira, rakanyanya kuitwa uye rakakura rekudzikama rakakosha mukuvandudza magetsi ekugadzirisa electrode.

•Calcination: Calcine zvigadzirwa zvemberi pakubvisa kusviba kwakadai kuti ubvise zvakadai sekunyorova uye kushamisika, kuwedzera dentity uye kusimba kwezvinhu zvisina kugadzirwa, uye kuvandudza maitiro avo uye anogadzikana.

•Kupwanya uye kugeda: Kupwanya uye kugeda nekukasira zvigadzirwa zvekushandisa zvakaringana kuti uwane kukodzera kugovaniswa kwekugovaniswa kwekugoverwa kwakasarudzika kwekutevera uye maitiro ekupfugama.

•Bata uye kupfugama: Zvigadzirwa zvakasiyana-siyana zvisina kuvharwa zvinobatwa zvinoenderana neyakaenzana, uye huwandu hwakakodzera hwemarongo anowedzerwa seyekuchinjika. Kukara kunoitwa pakudziya kwakanyanya kuti uvhenganise zvizere zvigadzirwa uye gadzira pasita ine zvakanaka plasticity.

•Kuumbwa: Pfumo panyama inoiswa mune imwe furati, uye electrode isina chinhu cheiyo inodiwa chimiro uye saizi inogadzirwa nekuwedzera, kuumbwa uye kumwe nzira dzekuumbwa.

•Calcination: Iyo Electrode isina chinhu yakagadziridzwa pakupisa kwakanyanya pasi pemhepo-yakasimba mamiriro ekuti canbonize iyo maronda tarn, inovandudza simba uye kuita kwealectrode, uye zvakare kubvisa tsvina.

•Kusimbisa: Electrode yakagadziriswa yakanyorwa mumubatanidzwa wemvura, seyakafanana nemwenje, resin, etc.

•Graphifization: Iyo yakasarudzika electrode inofemerwa mune yakakwirira-tembiricha grapitifional chando kushandura kabhoni mune graphiti carnstal chimiro, nekukonzera kuitisa kunhuwirira, kuparadzaniswa kwesirivha uye kupisa kwakanyanya kweiyo electrode.

•Machining: Electrode yakagadziriswa neElectrodics yakagadziriswa, yakadai sekutendeuka, inodhirowa, yekubira zvigadzirwa zvezvigadzirwa zvinosangana nezvinodiwa zvekuita zvakaringana uye nemhando imwe chete, uye madhirowa kana majoini ekubatana anoitwa.

•Minda yekushandisa

•Magetsi arc echoto steelmaking: Icho chinhu chakakosha chemagetsi epamusoro-semagetsi arc chirimwa chemagetsi

•Isina-ferrous simbi yekunyudza: Mukufunga kwekunyepedzera kwevasiri-fure, aluminium, uye zinc, rinoshandiswa kupa yakakwirira kupisa sosi, kusimudzira kunyungudutsa uye kunatsa mitezo, uye kunatsiridza kuchena uye mhando yesimbi.

•Dzimwe minda: Inogona zvakare kushandiswa muyero phosphorus kugadzirwa, maindasitiri silicon chinese, mamwe maindasitiri ekugadzira maindasitiri ekuita magetsi uye ekudziya mabasa ekugadzika magetsi mune aya maindasitiri kuti asangane nezvinodiwa zvekuita zvavanoda.

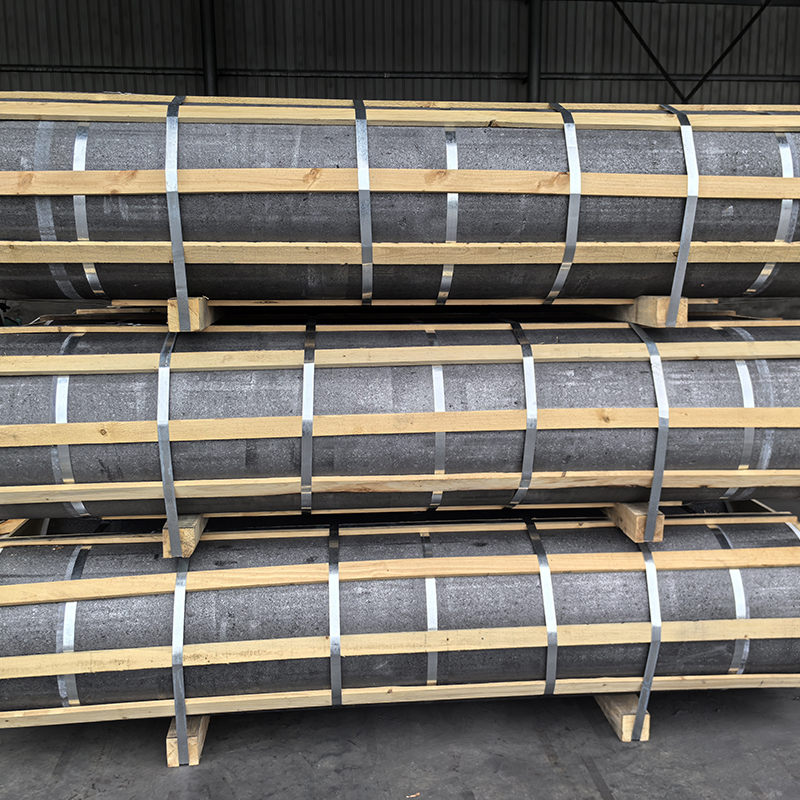

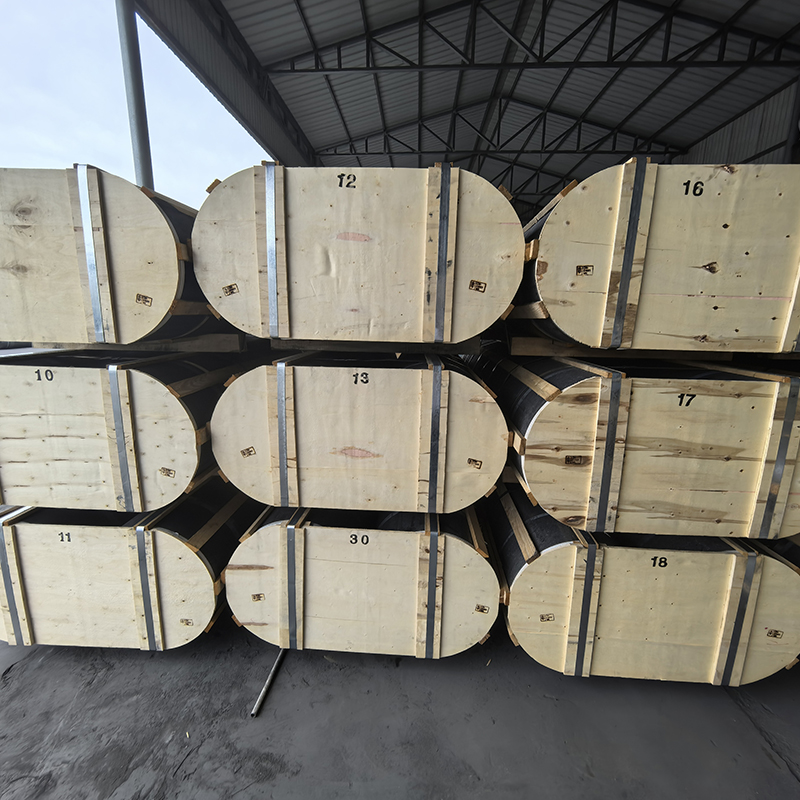

Kurongedza uye kuendesa

Kurongedza zvinyorwa: standard kurongedza muPallet.

Chiteshi: Tianjin Port