- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

Baaruud sare iyo kookaha baaruud hoose, gaar ahaan codsiyada birta iyo shubista. Si toos ah u soo saaray soo saaraha, oo kayd ah oo diyaar u ah shixnad degdeg ah

-

Electrodes garaafyada tayada sare leh, cabbirka 600mm, dhoofinta adduunka oo dhan waa la heli karaa

-

Kala duwanaansho buuxda oo ah electrodes graphite: 450, 500, 550 mm sizes diyaar ah, awood sare iyo ikhtiyaaro awood sare leh, dhammaan cabbirada kaydka

-

550mm koronto ultra-sare/awood sare leh oo garaafyo ah: iska caabin hoose, cufnaanta sare, iyo hormuudka yaraynta isticmaalka tamarta

-

RP korantada garaafka caadiga ah

-

ultra-High Power Graphite Electrode

-

UHP ultra high power graphite electrode

-

85-1260mm daboolida kala duwan oo buuxa, awood sare iyo ultra-high-power graphite electrodes - xudunta tamarta ee dhalada warshadaha

-

Sagaal-dalool crucible oo si gaar ah loogu talagalay qalabka korantada xun; waxa ku jira waxyaabo wasakhaysan oo hooseeya, iska caabin heerkul sare ah, iyo waafaqsanaanta hababka garaafaynta

-

Carburizer wareegsan

-

Electrodes garaafyada awooda sare leh: doorashada la door biday ee badbaadinta tamarta, isticmaalka yaraynta, iyo hufnaanta biraha oo la hagaajiyay

-

600mm dhexroor-awood sare iyo ultra-high-power graphite electrodes, koronto ku shaqeeya, heerkul sare u adkaysta, heerka warshadaha, xasilloon oo waara.

-

Warshada iibka tooska ah! UHP ultra-high electrodes, si gaar ah loogu talagalay foornooyinka laydhka ee korontada ku shaqeeya iyo foornooyinka sifaynta.

-

saxan garaafka

-

Graphite Crucible

-

Electrodes garaafyada awooda sare leh, dhexroorka 600 mm, dhoofinta

HP garaafyada elektiroonigga sare

HP graphite electrode Sharaxaad gaaban: Nooca: HP graphite electrode Codsiga: birta / birta birta dhererka: 1600 ~ 2800mm Fasalka: HP (awood sare) caabbinta (μω.m): 5.8-6.6 Cufnaanta muuqata (G/CM³): 1.65-1.7001000 heerkulka: 6 3TPI/4TPI/4TPIL Walxaha ceeriin: coke cirbad...

Sharaxaada

calaamadeeye

HP garaafyada elektiroonigga sare

Sharaxaad gaaban:

Nooca: HP graphite electrode

Codsiga: bir / birta birta ah

Dhererka: 1600 ~ 2800mm

Darajo: HP (awood sare)

Iska caabin (μω.m): 5.8-6.6

Cufnaanta muuqata (G/CM³): 1.65-1.70

Balaadhinta kulaylka: 100-600 3TPI/4TPI/4TPIL

Agabka ceeriin: kookaha irbadda, kookaha batroolka, garoonka daamurka dhuxusha

Faa'iidada: heerka isticmaalka hooseeya

Midabka: cawl madow

Dhexroorka: 250mm, 300mm, 400mm, 400mm, 450mm, 450mm, 500mm, 600mm, 650mm, 650mm, 650mm, 650mm, 700mm, 800mm, 800mm, 800mm

•Tilmaamaha waxqabadka

•Dhaqdhaqaaq sare: iska caabin hoose, inta u dhaxaysa 5.8-6.6μΩ・m, waxay si hufan u dhaqmi kartaa hadda, yaraynaysaa tamarta luminta, hagaajinta xasiloonida iyo hufnaanta, oo u ogolaato cufnaanta hadda u dhaxaysa 18-25A/cm².

•Iska caabin heerkul sare oo wanaagsan: Laga sameeyay alaab tayo sare leh sida kookaha batroolka iyo coke irbadda, ka dib daawaynta heerkulka sare, waxay ilaalin kartaa sifooyinka jirka iyo kiimikaad ee jawiga heerkulka sare mana fududa in la beddelo ama waxyeeleeyo.

•Awood farsamo sare leh: Waxay leedahay xoog foorarsi sare leh iyo iska caabin saameyn leh, ≥11.0MPa, waxay u adkeysan kartaa walbahaarka iyo saameynta weyn, ma fududa in la jebiyo inta lagu jiro isticmaalka, waxayna hubisaa xasilloonida iyo nolosha adeegga elektaroonigga.

•Iska caabbinta shoogga kulaylka wanaagsan: Habka kuleylka iyo qaboojinta joogtada ah ee wareegyada qaboojinta, waxay u adkeysan kartaa saameynta diiqada kulaylka, ma fududa in la dillaaco, diiriyo, iwm, waxayna hagaajinaysaa cimriga elektaroonigga ah.

•Waxa ku jira dambas hooseeya: Waxa ku jira dambaska ≤0.2%, wasakhda yar, waxay yarayn kartaa wasakhowga dhalaalaysa

•Habka wax soo saarka

•Xulashada alaabta ceeriin: Coke batroolka iyo kookaha irbadda ayaa ah isku geynta ugu weyn, taamurka dhuxushana waa xiraha. Waxaa ka mid ah, kookaha cirbadda waxay xisaabisaa qiyaastii 30%, iyo xooggeeda sare, dhaqdhaqaaqa sare iyo xasilloonida kuleylka sare ayaa muhiim u ah hagaajinta waxqabadka korantada.

•Calcination: Calcine alaabta ceeriin heerkul sare si aad meesha uga saarto wasakhda sida qoyaanka iyo kacsanaanta, kordhiso cufnaanta iyo xoogga alaabta ceeriin, oo aad u wanaajiso dhaqdhaqaaqooda iyo xasiloonida kulaylka.

•Burburinta iyo shiididda: Burburinta iyo shiididda alaabta ceeriin ee la kariyey si loo gaaro qaybinta cabbirka walxaha ku habboon ee habsocodyada iyo cajiinta xiga.

•Duubista iyo cajiin: Qalab cayriin oo kala duwan ayaa loo habeeyey iyadoo loo eegayo saami go'an, waxaana lagu daraa daamur dhuxul ah oo ku habboon xirmo ahaan. Kneading waxaa lagu fuliyaa heerkul sare si si buuxda loogu qaso alaabta ceeriin oo loo sameeyo koollo leh caag wanaagsan.

•Qaabaynta: Xabagta la cajiimay waxaa lagu dhejiyaa caaryar, iyo korantada bannaan ee qaabka iyo cabbirka loo baahan yahay waxaa lagu sameeyaa extrusion, qaabeynta iyo hababka kale ee wax-qabashada.

•Calcination: Korodhka bannaan ee bannaan waxa lagu xisaabiyaa heerkul sare oo hoos imanaya xaalado hawo-ku-hayn si loo kaarboonysiiyo daamurka dhuxusha, loo hagaajiyo xoogga iyo korriinka korantada, ugana saaro wasakhda.

•Uurka: Electrode-ka la kariyey waxa lagu dhex shubaa dareere wasakhaysan, sida daamurka dhuxusha, xabagta, iwm.

•Sawiraynta: Electrode impregnated waxaa graphitized in a foornada graphitization heerkulka sare si loogu badalo carbon amorphous qaab crystal graphite ah, oo sidaas hagaajinaysaa conductivity, conductivity kulaylka iyo caabbinta heerkulka sare ee electrode ah.

•Mashiinka: Electrode graphitized waxaa si farsamaysan loo farsameeyaa, sida leexinta, qodista, tuubada, iwm, si loo soo saaro alaabada korantada ee buuxisa shuruudaha saxnaanta cabbirka iyo tayada dusha sare, isla mar ahaantaana, dunta ama kala-goysyada isku xirka ayaa la farsameeyaa.

•Goobaha codsiga

•Samaynta birta foornada korantada: Waa qayb muhiim ah oo ka mid ah birta foornada foornada koronto ee awoodda sare leh, loo isticmaalo in lagu sameeyo hadda, abuurto arc koronto, u beddelo tamarta korantada tamarta kulaylka, ka dhig qiimaha foornada dhalaali oo si dhakhso ah u nadiifiso, hagaajinta waxtarka iyo tayada birta samaynta, iyo dhimista isticmaalka tamarta.

•Dhalinta birta aan birta ahayn: Habka dhalaalidda biraha aan biraha ahayn sida naxaasta, aluminium, iyo zinc, waxaa loo isticmaalaa in lagu bixiyo il kulaylka sare leh, kor loogu qaado dhalaalka iyo sifaynta biraha, iyo hagaajinta nadiifinta iyo tayada biraha.

•Beeraha kale: Waxa kale oo loo isticmaali karaa wax soo saarka fosfooraska jaalaha ah, dhalada silikon warshadaha, wax soo saarka abrasive iyo warshadaha kale si ay u bixiyaan conduction korantada iyo hawlaha kululaynta foornooyinka korontada ee warshadaha kuwan si ay u buuxiyaan shuruudaha geedi socodka wax soo saarka ay.

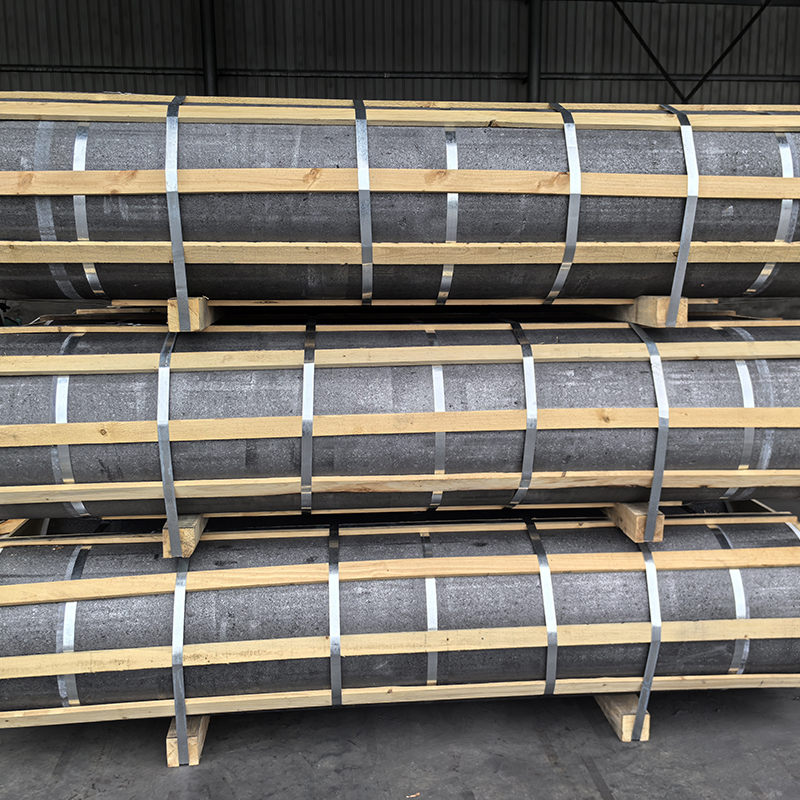

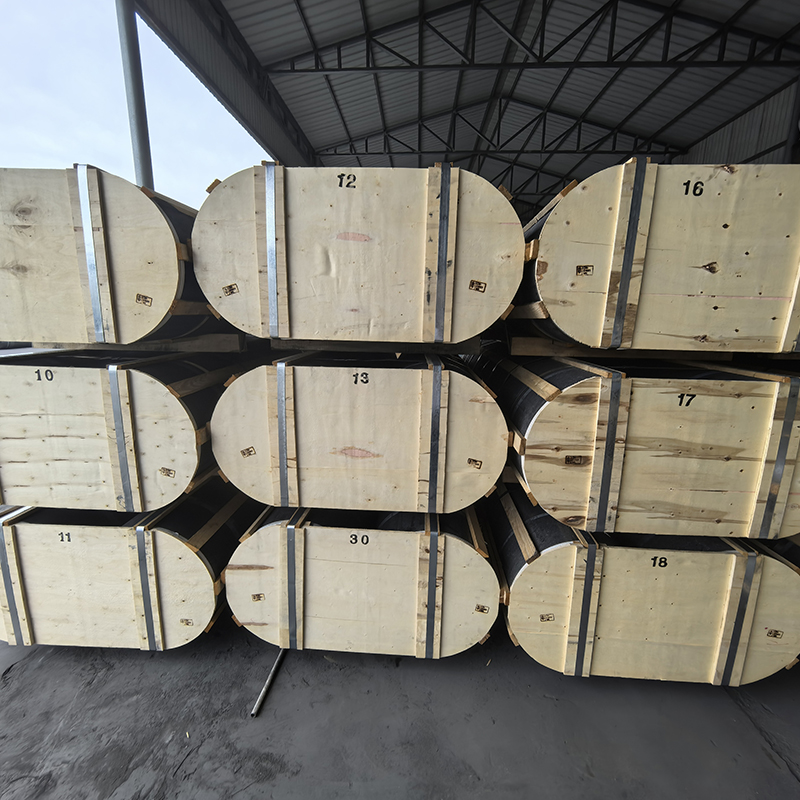

Baakadaha iyo gaarsiinta

Faahfaahinta Xirmooyinka: Baakadaha caadiga ah ee palette.

Dekadda: Dekedda Tianjin