- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Li-Electrode tsa Graphite tsa Matla a Phahameng a Matla a Matla, Litšireletso tse Tlase le Ts'ebetso e Phahameng, Lithupa / Lihokelo

2025-12-25

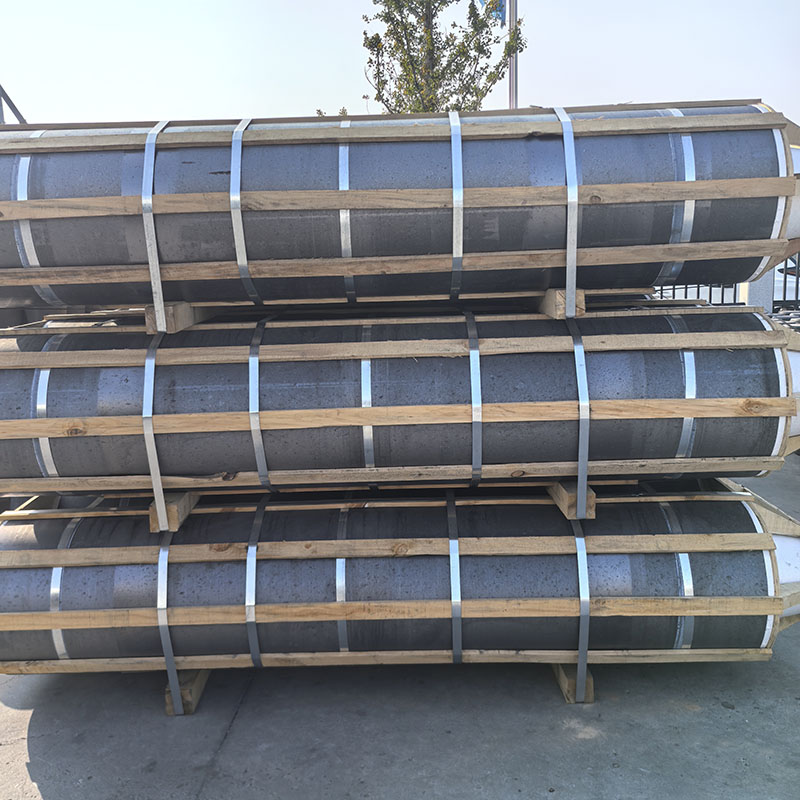

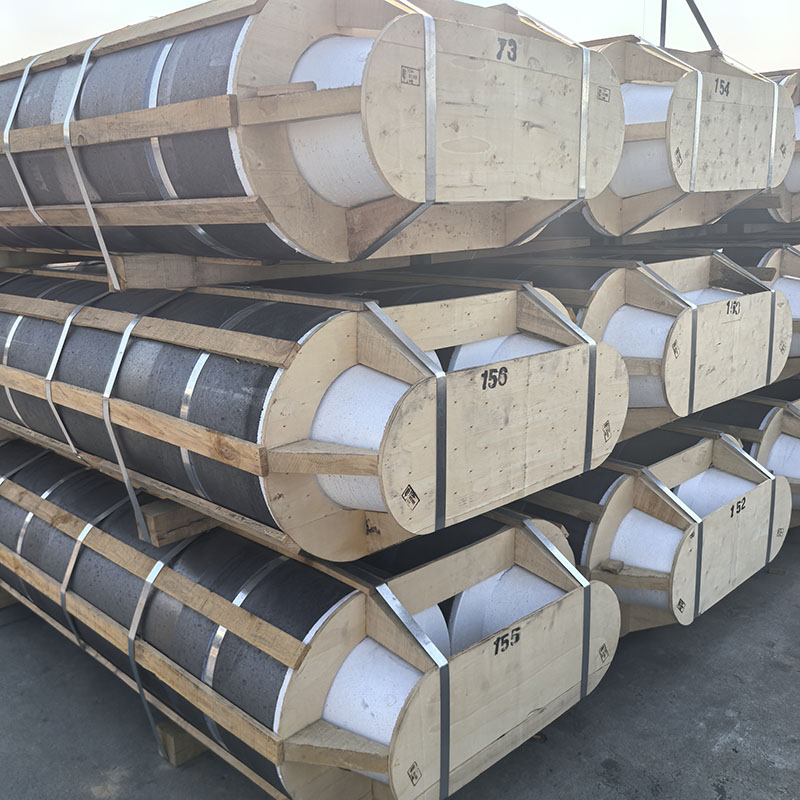

Lebitso la Sehlahisoa: Ultra-High Power Graphite Electrode

Litlhaloso tsa Sehlahisoa: Diameter Φ200-600mm, bolelele bo ka khonehang; e nang le lihokelo tsa li-electrode tse tloaelehileng tsa naha, tse tsamaellanang le libono tse fapaneng tsa li-arc tsa motlakase tse phahameng haholo.

I. Melemo ea Konokono

1. High Conductivity and Low Resistance: E entsoe ka lisebelisoa tse tala tsa nale ea coke 'me e tšoaroa ka graphitization e phahameng ea mocheso, e bonts'a conductivity e babatsehang, ka katleho ho fokotsa tšebeliso ea matla a sebōpi sa motlakase le ho ntlafatsa bokhoni ba ho qhibilihisa.

2. Thermal Shock Resistance le Corrosion Resistance: Sebopeho se teteaneng sa ka hare se fa sehlahisoa ho hanyetsa mocheso o phahameng. Ha e na oxidized kapa ho petsoha habonolo libakeng tse nang le mocheso o phahameng oa mocheso, 'me bophelo ba eona ba ts'ebeletso bo feta hole ba li-electrode tse tloaelehileng.

3. Mokhoa o nepahetseng le ho ikamahanya le maemo a matla: Ho nepahala ho entsoeng ka lisebelisoa tsa CNC, sefahleho sa ho qetela sa electrode se na le flatness e phahameng, ho netefatsa hore ho na le khokahanyo e thata le sehokelo, ho kenya habonolo, le ho lumellana ho tsitsitseng le lisebelisoa tsa motlakase tse nang le matla a phahameng a matla a ho etsa litšepe tsa motlakase, libōpi tsa arc tse koahetsoeng ke metsi, le lisebelisoa tse ling.

4. Fektheri ea Mohloli e nang le Boleng bo Laolehang: Re na le mohala oa rona oa tlhahiso, o nang le tlhahlobo ea boleng bo felletseng ho tloha ho khetho ea thepa e tala ho isa ho phepelo ea sehlahisoa se felileng. E kopana le litekanyetso tsa naha tsa indasteri ea metallurgic mme e ts'ehetsa phepelo ea thepa e ngata le mokhoa o sa tloaelehang.

II. Scenarios tse sebetsang

E sebelisoa haholo ho etsa tšepe ea tšepe ea motlakase ea matla a phahameng a phahameng, ho qhibilihisa tšepe e se nang ferrous, tlhahiso ea ferroalloy, le masimo a mang, ke ntho e ka sehloohong e ka sebelisoang bakeng sa ho finyella ts'ebetso e sebetsang hantle le e bolokang matla indastering ea metallurgic.

III. Tiisetso ya Tshebeletso

1. E ts'ehetsa litlhaloso le boholo bo ikhethileng ho fihlela litlhoko tsa tlhahiso ea motho ka mong tsa bareki ba fapaneng;

2. Ho reka ka bongata ho natefeloa ke litheko tse tobileng tsa feme, ka mehala ea thepa e ikemiselitseng ho netefatsa hore ho tsamaisoa ho bolokehile le ka nako;

3. E fana ka likeletso tse felletseng tsa pele ho thekiso ea tekheniki le lits'ebeletso tsa ho latedisa boleng ba kamora thekiso ho rarolla mathata a bareki.