- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Understanding and Utilizing Graphitized Petroleum Coke

2025-07-24

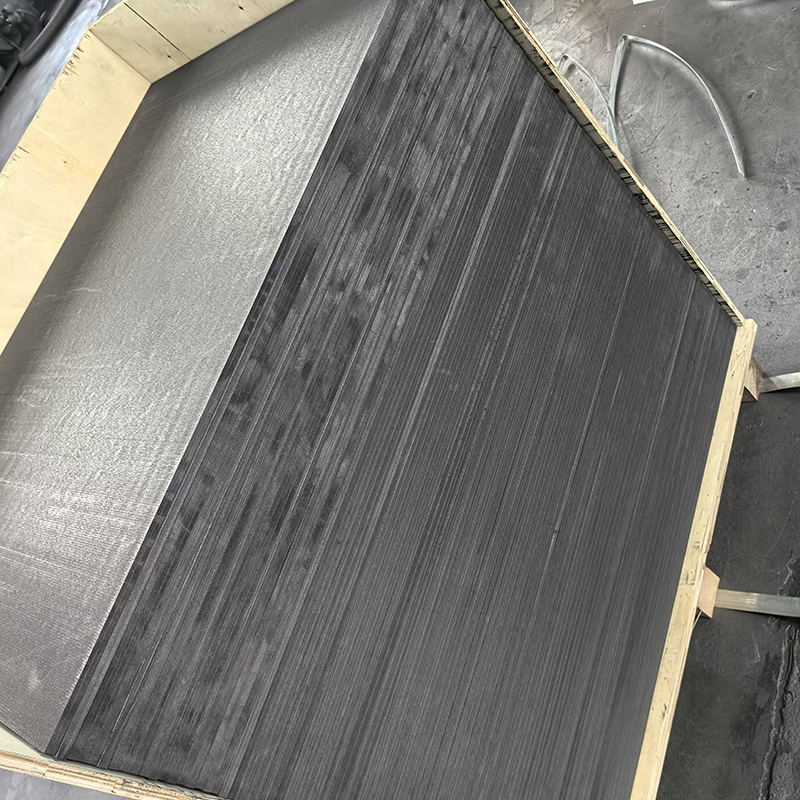

Understanding and Utilizing Graphitized Petroleum Coke

This comprehensive guide explores graphitized petroleum coke (GPC), detailing its properties, applications, and market considerations. Learn about its manufacturing process, key characteristics, and the industries that rely on this crucial material. We’ll also delve into the differences between GPC and other forms of coke and explore its future prospects.

What is Graphitized Petroleum Coke?

Graphitized petroleum coke is a high-carbon material produced by the calcination and graphitization of petroleum coke. This process involves heating petroleum coke to extremely high temperatures, typically above 2500°C, under controlled conditions. This treatment significantly alters its physical and chemical properties, resulting in a product with enhanced strength, electrical conductivity, and thermal stability. Unlike other forms of coke, GPC exhibits a highly ordered, crystalline structure similar to graphite.

Manufacturing Process of Graphitized Petroleum Coke

The creation of GPC involves several key stages: Firstly, petroleum coke is produced as a byproduct of petroleum refining. This coke is then calcined at high temperatures to remove volatile matter and increase its carbon content. Finally, the calcined coke undergoes graphitization, a high-temperature process that rearranges the carbon atoms into a more ordered structure. The exact parameters of each stage significantly influence the final properties of the GPC produced.

Key Properties and Characteristics of GPC

The remarkable properties of graphitized petroleum coke make it valuable in numerous industrial applications. These include:

- High Carbon Content: Typically exceeding 99%.

- Excellent Electrical Conductivity: Crucial for its use in electrodes.

- High Thermal Conductivity: Enables efficient heat transfer.

- Exceptional Thermal Stability: Able to withstand extreme temperatures.

- Chemical Inertness: Resistant to many corrosive substances.

Applications of Graphitized Petroleum Coke

GPC finds wide use across various sectors. Some prominent examples include:

Electrode Manufacturing

A major application is in the manufacturing of electrodes for electric arc furnaces used in steelmaking and other metallurgical processes. The high electrical conductivity and thermal stability of GPC make it ideal for this demanding application. Hebei Yaofa Carbon Co., Ltd. (https://www.yaofatansu.com/) is a leading supplier of high-quality carbon products, including those utilizing GPC.

Other Industrial Applications

Beyond electrodes, GPC also serves as a crucial component in:

- Carbon Brushes

- Nuclear Graphite

- High-Temperature Furnace Linings

- Lubricants

GPC vs. Other Forms of Coke

| Property | Graphitized Petroleum Coke (GPC) | Petroleum Coke | Calcined Petroleum Coke |

|---|---|---|---|

| Crystalline Structure | Highly Ordered | Amorphous | Partially Ordered |

| Electrical Conductivity | High | Low | Moderate |

| Thermal Conductivity | High | Low | Moderate |

The Future of Graphitized Petroleum Coke

The demand for GPC is expected to continue growing, driven by the increasing global steel production and the expansion of other industrial sectors relying on its unique properties. Ongoing research focuses on improving the manufacturing process to enhance its performance characteristics and reduce its environmental impact. The development of sustainable and efficient production methods will be crucial for the long-term viability of GPC.

Disclaimer: This information is for general knowledge and informational purposes only, and does not constitute professional advice. While every effort has been made to ensure accuracy, Hebei Yaofa Carbon Co., Ltd. is not responsible for any errors or omissions.