- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

-

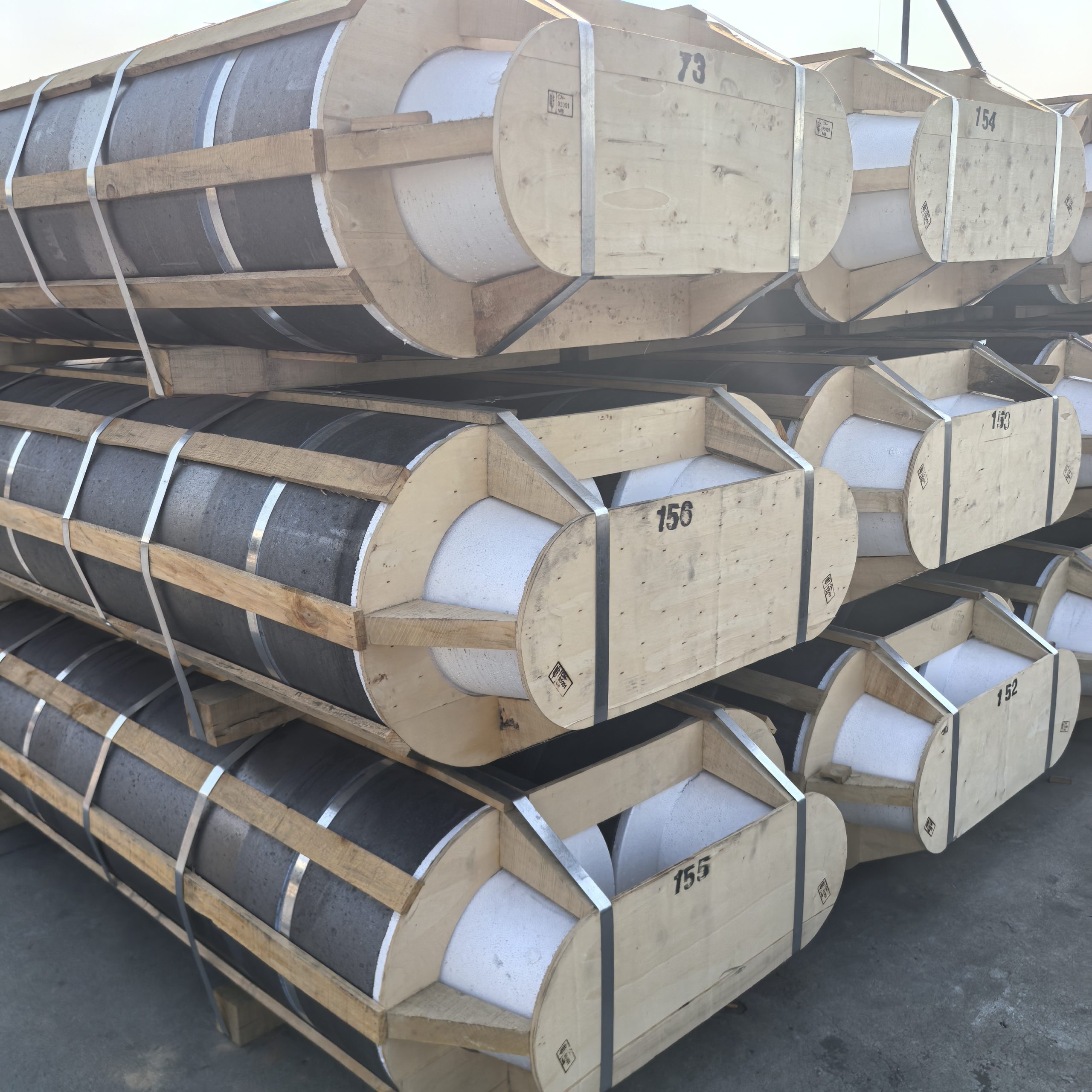

600mm diameter high-power and ultra-high-power graphite electrodes, electrically conductive, high-temperature resistant, industrial-grade, stable and durable.

-

85-1260mm full range coverage, high-power and ultra-high-power graphite electrodes – the energy core of industrial smelting

-

High-temperature resistant graphite plates: conductive, thermally conductive, and corrosion-resistant; custom processing available for industrial furnaces

-

RP normal power graphite electrode

-

450mm ultra-high/high-power graphite electrodes, high density and low resistance, supplied directly from the manufacturer.

-

Metallurgical steelmaking ultra-high power graphite electrodes, high temperature resistant and impact resistant, direct supply from the manufacturer

-

High-sulfur and low-sulfur petroleum coke, specifically for metallurgy and casting applications. Directly supplied by the manufacturer, in stock and ready for immediate shipment

-

600mm ultra-high power graphite electrodes with high density and low resistance: setting a new benchmark for smelting efficiency

-

Nine-hole crucible specifically designed for negative electrode materials; features low impurity content, high temperature resistance, and compatibility with graphitization processes

-

Graphite plate

-

HP high power graphite electrode

-

High-power graphite electrode rods, specifically for steelmaking and refining. In stock and ready for immediate shipment. Bulk orders receive discounted pricing.

-

High-quality graphite powder available in stock, with a full range of specifications and customizable options.

-

Calcined petroleum coke carbon additive: high absorption rate, adjustable particle size, ideal for casting and metallurgy

-

High-power graphite electrodes, 600 mm diameter, for export.

-

High-temperature resistant silicon carbide crucible, specially designed for melting aluminum and copper, corrosion-resistant and impact-resistant, direct from the manufacturer.

Ultra-High Power Graphite Electrode

Product Specifications Diameter: Φ200-600mm, length customizable; equipped with national standard electrode joints, suitable for various ultra-high power electric arc furnaces. Core Advantages **High Conductivity & Low Resistance**: Made from high-quality needle coke and processed by high-te...

Description

marker

Product Specifications Diameter: Φ200-600mm, length customizable; equipped with national standard electrode joints, suitable for various ultra-high power electric arc furnaces.

- Core Advantages

- **High Conductivity & Low Resistance**: Made from high-quality needle coke and processed by high-temperature graphitization, it boasts excellent conductivity, effectively reducing electric furnace energy consumption and improving smelting efficiency.

- **Thermal Shock & Corrosion Resistance**: The dense internal structure endows the product with strong thermal shock resistance. It is not easy to oxidize or crack in high-temperature smelting environments, and has a much longer service life than ordinary electrodes.

- **Precision Machining & Strong Adaptability**: Precision machined by CNC lathes, the electrode has high end face flatness, connects tightly with joints, and is easy to install. It can stably adapt to ultra-high power steelmaking electric arc furnaces, submerged arc furnaces and other equipment.

- **Source Factory with Controllable Quality**: With its own production line, it implements full-process quality inspection from raw material screening to finished product delivery, complying with national metallurgical industry standards. It supports bulk spot supply and non-standard customization. ## II. Application Scenarios Widely used in ultra-high power electric arc furnace steelmaking, non-ferrous metal smelting, ferroalloy production and other fields, it is a core consumable for achieving efficient and energy-saving smelting in the metallurgical industry.

- Service Guarantee

- Customization of specifications and sizes is supported to meet the personalized production needs of different customers.

- Bulk purchasers enjoy factory direct prices, and logistics line distribution ensures safe and on-time delivery of goods.

- Provide comprehensive pre-sales technical consultation and after-sales quality tracking services to eliminate customers’ worries during use.