- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur

Imikhiqizo

-

I-Electrode yamandla we-graphite ephezulu ye-HP

-

Isengezo se-petroleum coke carbon esine-calcined: izinga lokumunca eliphezulu, usayizi wezinhlayiyana oguquguqukayo, olungele ukuphonsa kanye nokusansimbi

-

960 Graphite Electrodes – Amandla Aphezulu, Amandla Aphakeme Kakhulu – Ukuthumela Imikhumbi Emhlabeni Wonke

-

Ukudayiswa okuqondile kwasefekthri! Ama-electrode anamandla aphezulu e-UHP, adizayinelwe ngokukhethekile iziko likagesi ze-arc kanye neziko lokucwenga.

-

Ama-electrode e-graphite ekhwalithi ephezulu, usayizi we-600mm, ukuthunyelwa komhlaba wonke kuyatholakala

-

I-Ultra-High Power Graphite Electrode

-

I-Electrode yamandla ajwayelekile ye-RP

-

450mm ultra-high/high-power graphite electrode, ukuminyana okuphezulu nokumelana okuphansi, ahlinzekwe ngokuqondile kumkhiqizi.

-

85-1260mm ukufakwa kobubanzi obugcwele, amandla aphezulu kanye nama-electrode e-graphite aphezulu kakhulu - umnyombo wamandla wokuncibilikiswa kwezimboni

-

I-granular carriburizer

-

Amapuleti e-graphite amelana nezinga lokushisa eliphezulu: ayakwazi ukuqhubekisa, aphathe ukushisa, amelana nokugqwala; ukucutshungulwa ngokwezifiso okutholakalayo kweziko lezimboni

-

I-Metallurgical steelmaking ultra-high power graphite electrode, ukumelana nezinga lokushisa eliphezulu futhi imelana nomthelela, ukunikezwa okuqondile okuvela kumkhiqizi

-

Ipuleti le-graphite

-

Impushana ye-graphite yekhwalithi ephezulu etholakala esitokweni, enohlu olugcwele lwezicaciso kanye nezinketho ongazikhetha.

-

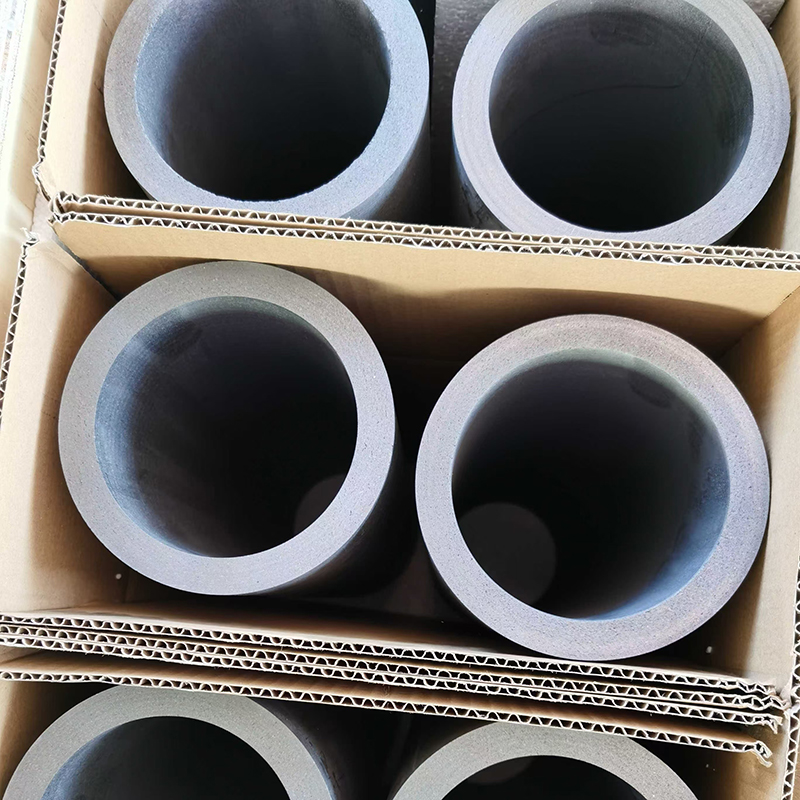

I-silicon carbide crucible ekwazi ukumelana nokushisa okuphezulu, edizayinelwe ngokukhethekile ukuncibilika i-aluminium nethusi, imelana nokugqwala futhi imelana nomthelela, isuka kumkhiqizi.

-

UHP Ultra ophakeme graphite graphite electrode

I-graphite ecashile

Izithako eziyinhloko ze-graphite ezibalulekile kanye nesakhiwo • Izici zesakhiwo: Ine-cr ephakathi ...

Ukufanisa

okokulakatha

I-graphite ecashile

Izithako eziphambili nesakhiwo

•Izithako eziphambili: Ngokuyinhloko eyakhiwa i-graphite, imvamisa equkethe amakhabhoni angaphezu kwama-90%, futhi ingangeza inani elincane lobumba, i-silicon carbide nezinye izengezo zokuthuthukisa ukusebenza kwayo.

•Izici Zokwakheka: Inesakhiwo esijwayelekile se-crystal, futhi izingqimba ze-graphite ziboshwe ngamabutho abuthakathaka we-van der Waals. Lesi sakhiwo sinikeza i-graphite ebethelwe izinga lokushisa eliphakeme lokushisa, ukuqhutshwa kanye nokuthambisa.

Izici Zokusebenza

•Ukumelana nokushisa okuphezulu okuphezulu: Ingamelana namazinga okushisa aphezulu angu-1500 ℃ -2000 ℃, futhi asakwazi ukugcina ukuqina okuhle ezindaweni eziphakeme zokushisa, futhi akulula ukuthambisa nokumona.

•Ukusebenza okuhle okushisayo: Ingashisa ngokushesha futhi ngokulinganayo ukudlulisa ukushisa, ukuze izinto zokwenziwa zibe ne-empini zifudumele ngokulinganayo, okulungele ukusabela kwamakhemikhali kanye nezinqubo zokunqwabelana, futhi kungathuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

•Ukuqina okuhle kwamakhemikhali: Ezindaweni eziningi zamakhemikhali ezivela emazingeni okushisa asekamelweni kuya ekushiseni okuphezulu, ama-graphite ama-graphiores anokumelana kahle nokuqina, alkalis namanye amakhemikhali, angaqinisekisa ubumsulwa bezinto ezisetshenzisiwe, futhi ulungele ukubhema nezindlela ezahlukahlukene zamakhemikhali.

•Izakhiwo ezinhle zemishini: Inamandla athile nokumelana nomthelela, akulula ukuhlukana ngesikhathi sokulayisha nokulayisha nokusebenzisa, futhi kungamelana nengcindezi ethile yemishini.

Izindawo zohlelo lokusebenza

•Ukubhema insimbi: Kusetshenziswe kabanzi ekunyisweni kwezinsimbi ezingezona nezinsimbi ezinjenge-alloys enjengegolide, isiliva, ithusi kanye ne-aluminium. Inganikeza indawo yokushisa ephezulu yokubhema insimbi, iqinisekisa ukuthi insimbi incibilike ngokuphelele futhi ixubene kahle, futhi ithuthukise ubumsulwa nekhwalithi yensimbi.

•Ukuhlolwa kwamakhemikhali: Elebhu, kuvame ukusetshenziselwa ukusabela kwamakhemikhali okushisa okuphezulu, izivivinyo ezincibilikayo, kanye nemisebenzi yesampula yokuhamba. Ingasetshenziswa njengesikebhe sokuphendula ukuze uhlangabezane nezidingo zokuhlolwa okuhlukahlukene kwamakhemikhali zokushisa okuphezulu nokuqina kwamakhemikhali.

•Ukukhiqiza ingilazi: Enqubweni yokukhiqiza ingilazi, isetshenziselwa ukuncibilikisa izinto eziluhlaza zengilazi, ezisiza ukuthuthukisa ukusebenza kahle nokufakelwa kwengilazi futhi kuthuthukise ikhwalithi nokusebenza kwengilazi.

Izinhlobo

•I-graphite ejwayelekile enobuhlakani: Kwenziwe nge-graphite yemvelo nobumba, kushibhile futhi kufanelekile ngokubheme okujwayelekile kwensimbi kanye nokuhlolwa.

•Igrafu yokuhlanza okuphezulu enobunzima: Kwenziwe ngezinto zokuhlanza izithonjana zokuhlanza okuphezulu futhi kucutshungulwa ubuchwepheshe obukhethekile, kunobumsulwa obuphakeme, ukumelana okungcono okuphezulu okuphezulu nokuqina kwamakhemikhali. Ilungele ukubhema kwensimbi okuyigugu nokuhlolwa okuphezulu kwamakhemikhali ngezidingo eziphakeme zokuhlanzeka.

•I-Silicon Carbide graphible ebekiwe: Ukungeza izinto ezifana ne-silicon Carbide to graphite kuthuthukisa amandla, ukumelana nokushisa okuphezulu nokumelana nokushaqeka okushisayo kwe-ebekiwe. Ivame ukusetshenziselwa ukunyibilikisa nokuphendula ezindaweni eziphakeme zokushisa nezindawo ezilimazayo.